Full-automatic tin paste printer for cleaning

A solder paste printing machine, fully automatic technology, used in printing machines, rotary printing machines, screen printing machines, etc., can solve the problems of affecting the yield, difficult to rule out that the circuit board is not stained with dust, and cannot be used normally. Improve utilization, facilitate flushing, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

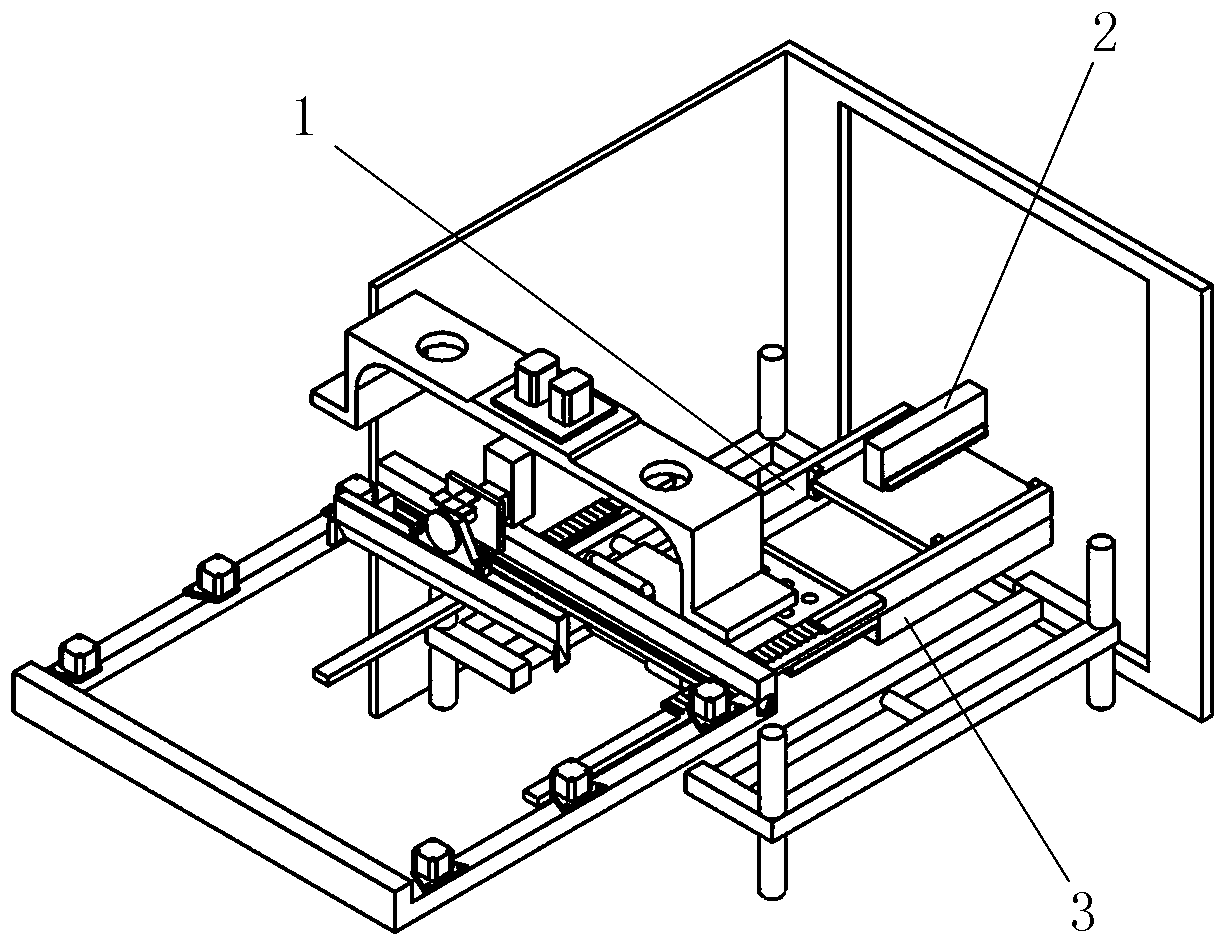

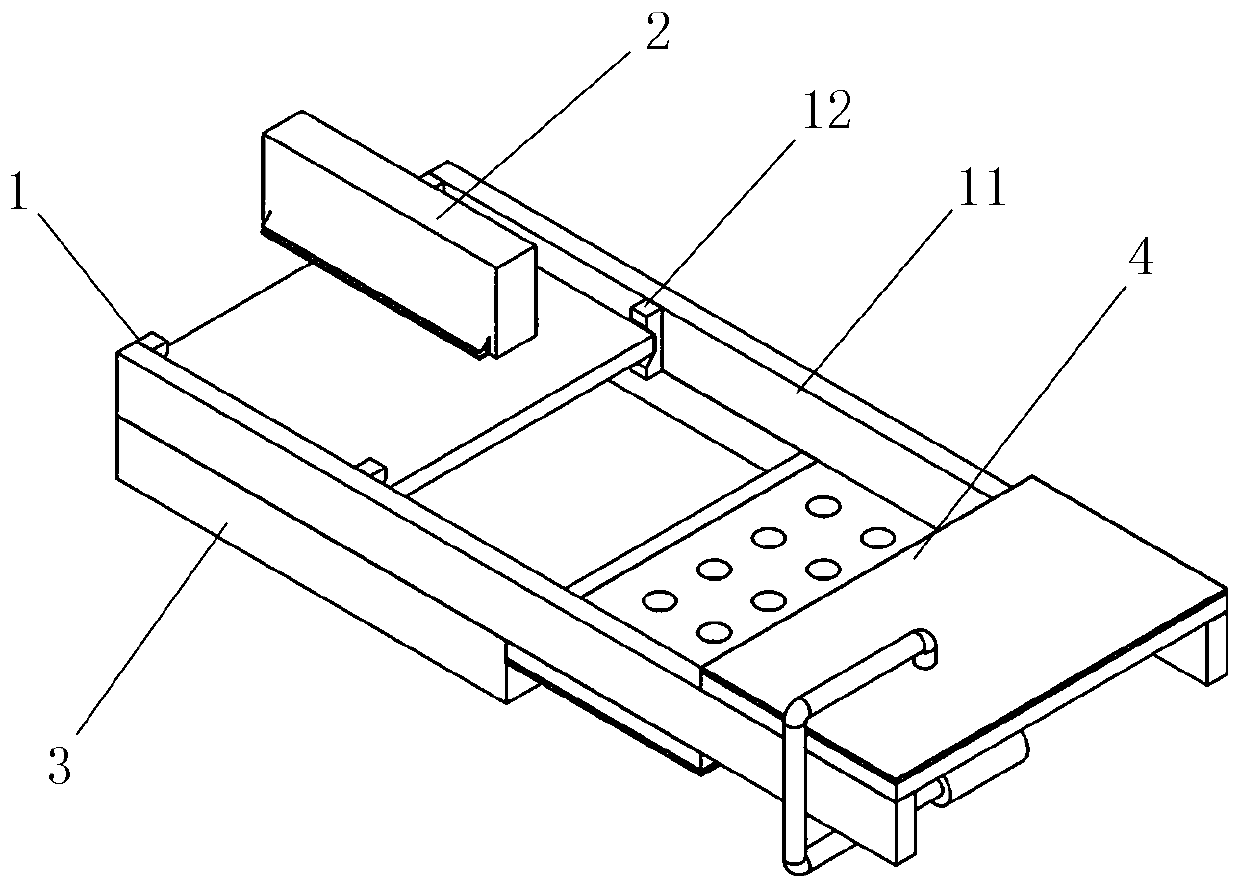

[0033] Example 1, such as figure 1 Shown is an overall schematic diagram of a clean automatic solder paste printing machine, a clean automatic solder paste printing machine, including the casing, clamping and lifting system, platform correction system, guide rail transportation system, and stencil frame clamping system , scraper printing system and follow-up cleaning system, which also includes the pre-cleaning system, such as figure 2 As shown, the pre-cleaning system includes a splint track 1 for clamping and moving the circuit board, a first water outlet 2 for spraying water on the circuit board, a water collection bottom tank 3 for collecting water flowing through the circuit board, and In the drying part 4 of the drying circuit board, the first water outlet 2 is located above the entrance of the splint track 1, the water collection bottom tank 3 is located below the splint track 1, and the drying part 4 is located at the end of the splint track 1. The splint track 1 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com