Edge tightening process for cabinet

A kind of craft and cabinet technology, applied in the field of furniture, can solve problems such as panel deformation, water infiltration, deliquescence, etc., and achieve the effect of reducing the probability of curling away from the panel and stabilizing the connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

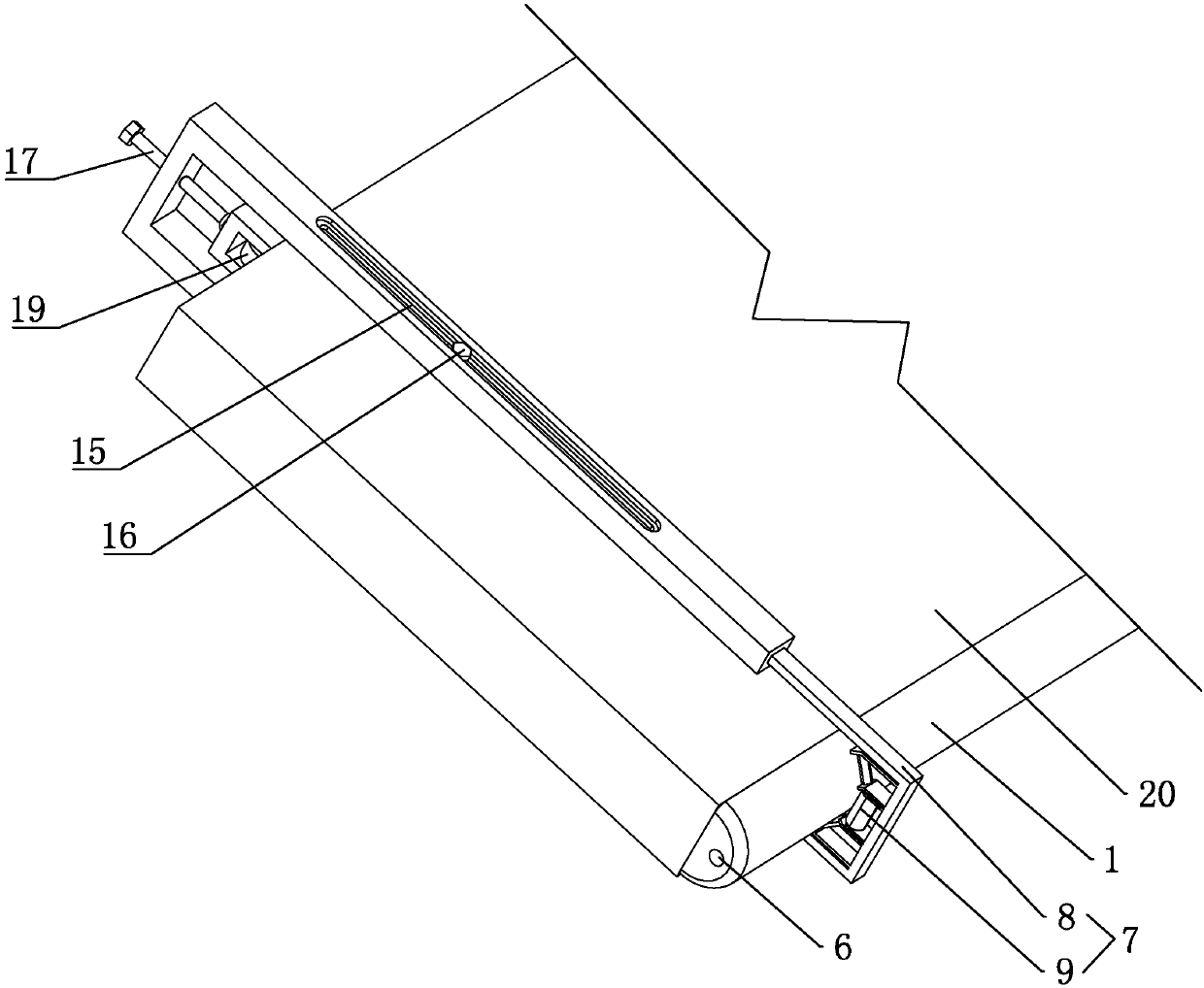

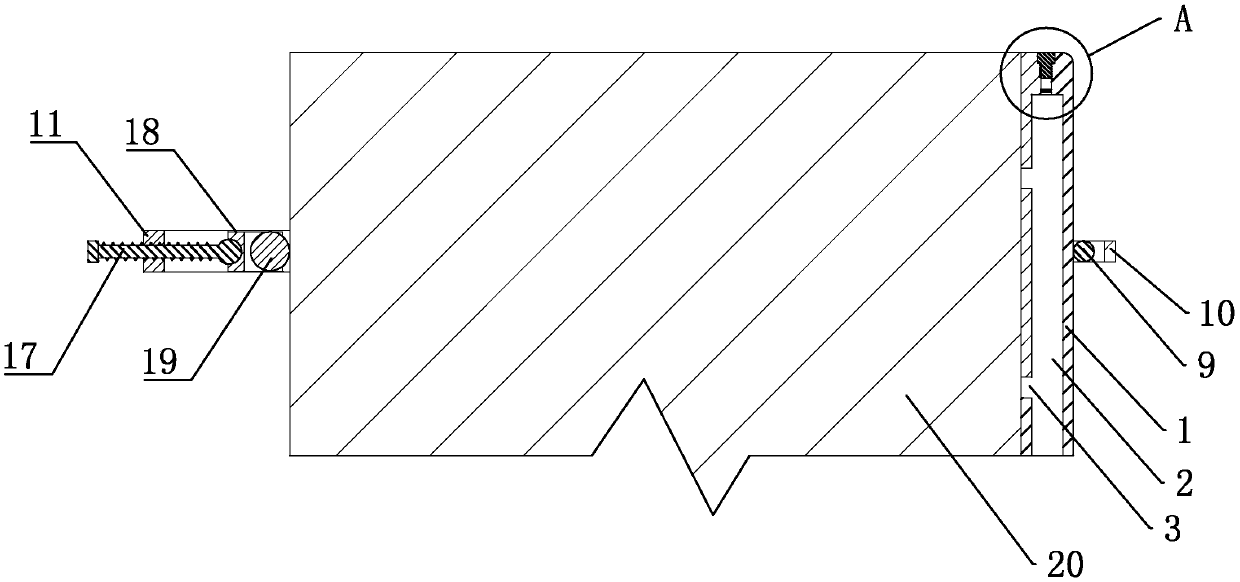

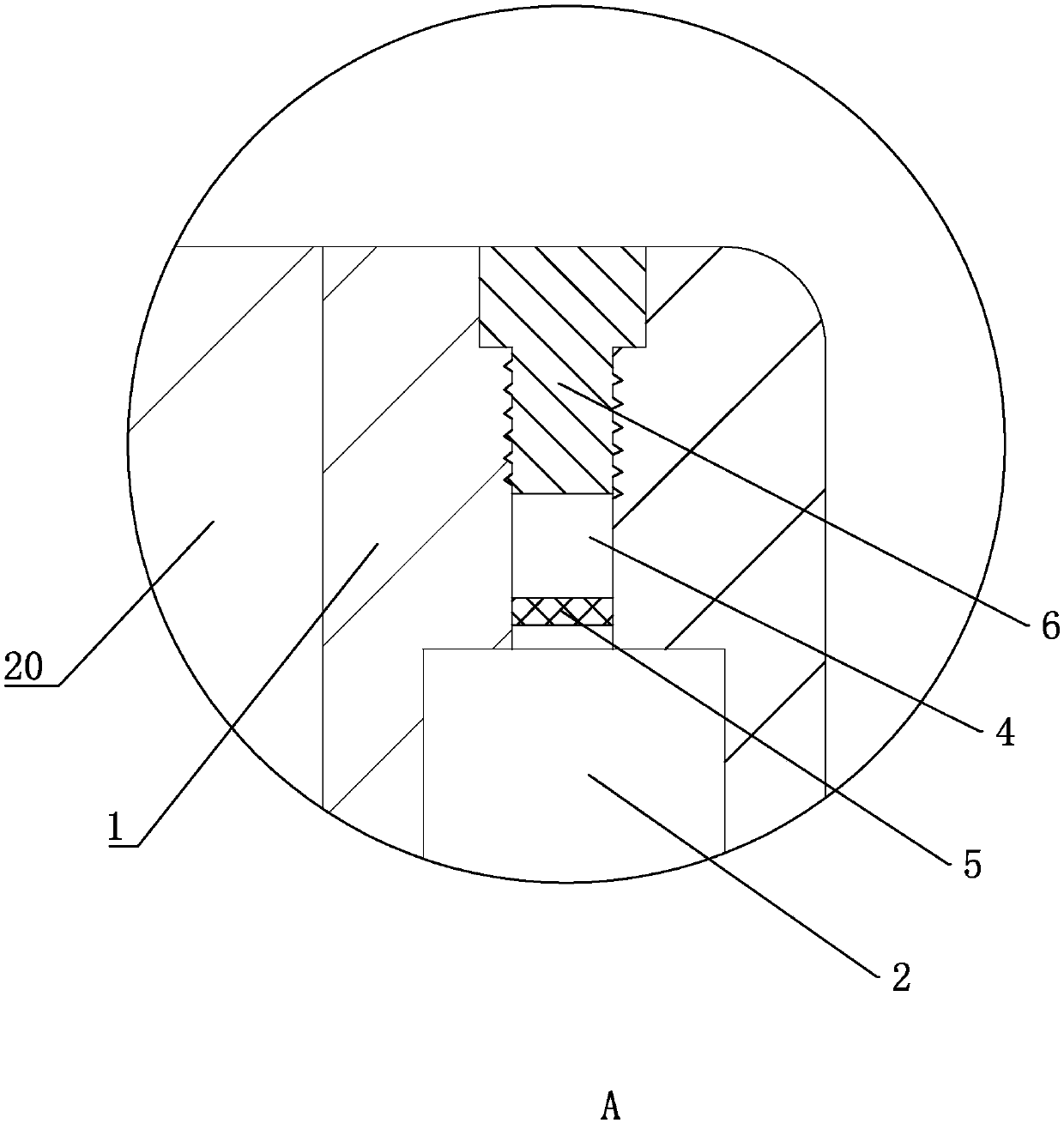

[0044] Such as figure 1 As shown, an edge banding 1 used for closing cabinets, the outer circumference of the section of the edge banding 1 is arc-shaped, and both ends of the edge banding 1 have rounded corners. Such as figure 2 As shown, a cavity 2 is provided inside the edge banding strip 1 , and a through hole 3 is opened on one end surface of the edge banding strip 1 , and the through hole 3 communicates with the cavity 2 . Such as image 3 As shown, one side of the edge banding strip 1 is provided with an air extraction hole 4 communicating with the cavity 2, and the cross section of the air extraction hole 4 is T-shaped. The lower end of the air extraction hole 4 is fixedly provided with a rubber membrane 5 , and the rubber membrane 5 seals the air extraction hole 4 . A sealing cover 6 is threadedly connected to the air extraction hole 4; when the sealing cover 6 is tightened, the sealing cover 6 is embedded in the air extraction hole 4 and seals the air extraction ...

Embodiment 2

[0046] Such as figure 1 As shown, an auxiliary device 7 for edge trimming of cabinets includes a frame 8 and pressing rollers 9 . The frame 8 is configured as a frame and sheathed outside the panel 20 . Such as Figure 4 As shown, the rack 8 includes a first bar 10 , a second bar 11 and a third bar 12 . The first rod 10 and the second rod 11 are arranged in the vertical direction, and the third rod 12 is arranged in the horizontal direction. There are two third rods 12, and two ends of one third rod 12 are fixedly connected to the upper ends of the first rod 10 and the second rod 11 respectively. Two ends of another third rod 12 are fixedly connected to the lower ends of the first rod 10 and the second rod 11 respectively.

[0047]Such as Figure 4 As shown, the third rod 12 is telescopically arranged. The third rod 12 includes a fixed rod 13 and a sliding rod 14 . One end of the fixed rod 13 is fixedly connected to the first rod 10 , and one end of the sliding rod 14 i...

Embodiment 3

[0050] An edge trimming process for a cabinet, comprising the following steps,

[0051] S1, using a blade to cut off the protrusion on the end face of the plane plate 20;

[0052] S2, use coarse sandpaper to roughen the end face of the panel 20;

[0053] S3, coating adhesive glue on the end face of the panel 20;

[0054] S4, bonding one end of the edge strip 1 to one end of the panel 20;

[0055] S5. Gradually attach the edge banding strip 1 to the end surface of the panel 20. At this time, the through hole 3 of the edge banding strip 1 is located on the side of the edge banding strip 1 opposite to the panel 20;

[0056] S6, insert the needle of the syringe into the rubber membrane 5, extract the air in the cavity 2, reduce the pressure in the cavity 2, make the atmospheric pressure press the edge band 1 on the panel 20, and improve the edge band 1 and The tightness between the panels 20; when the needle is pulled out after the extraction is completed, the rubber membrane 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com