Clamp and machine tool

A fixture and machine tool technology, applied in the field of fixture manufacturing, can solve the problems of waste, inability to process machine tools, increased equipment and site investment, etc., and achieve the effect of reducing installation, saving time and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

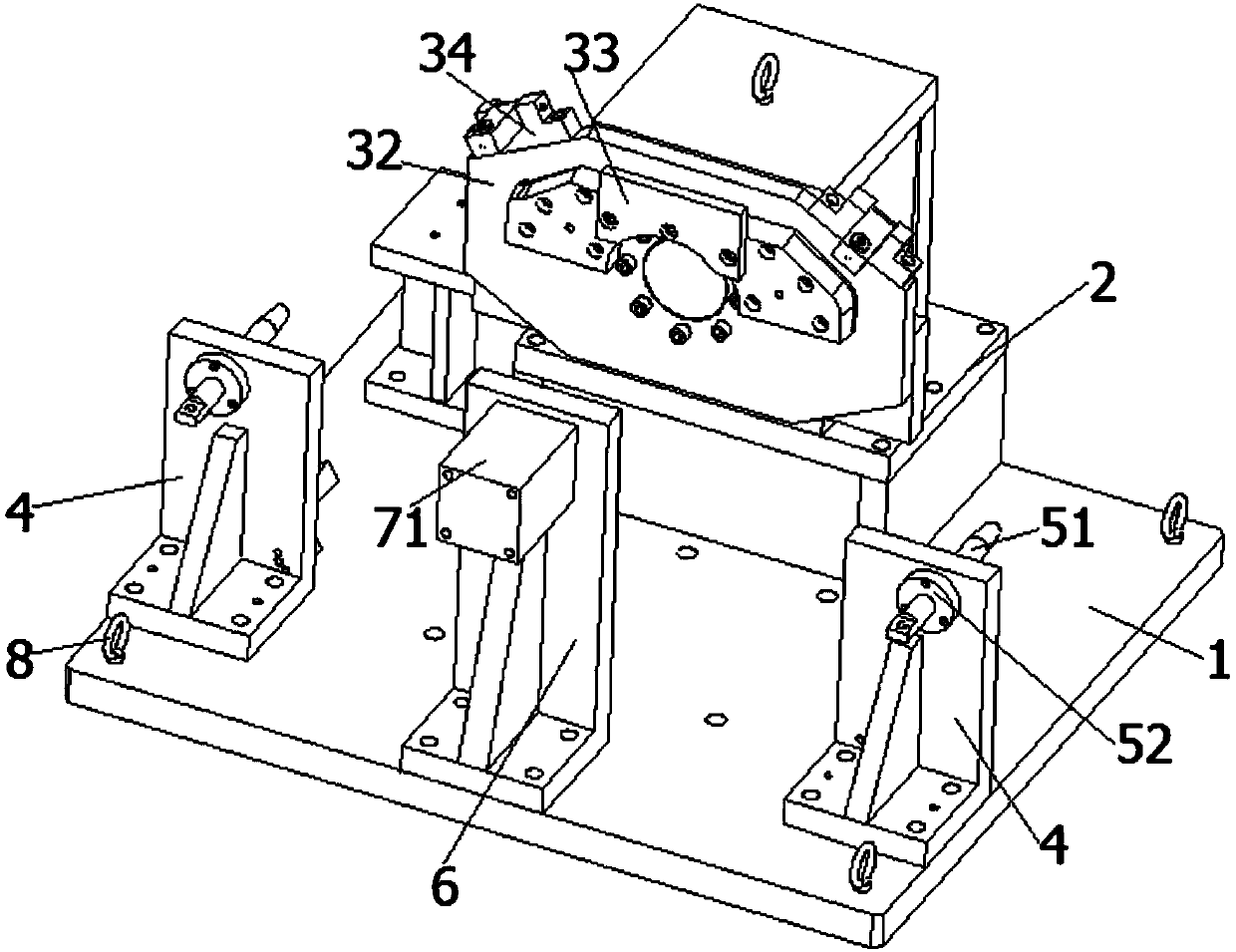

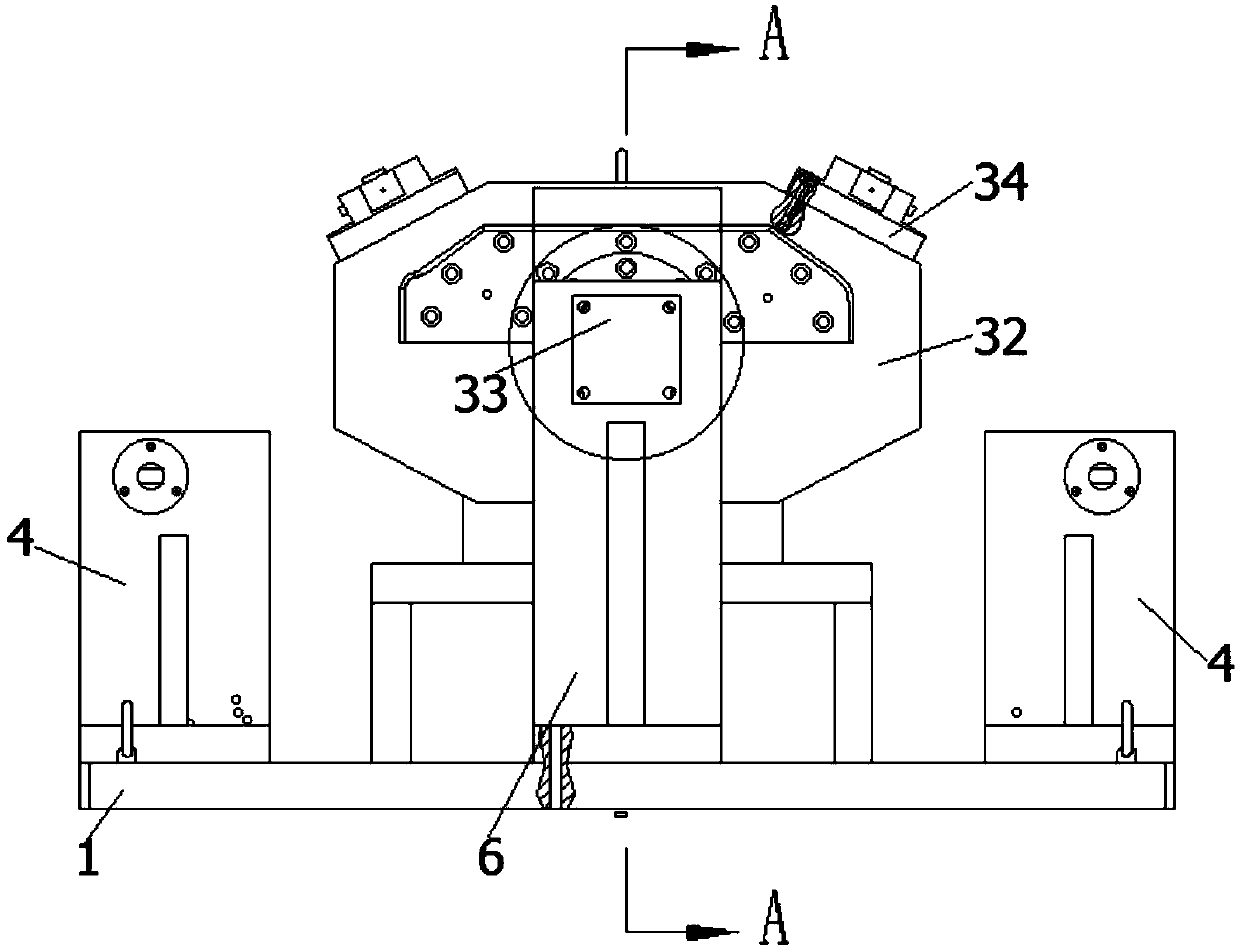

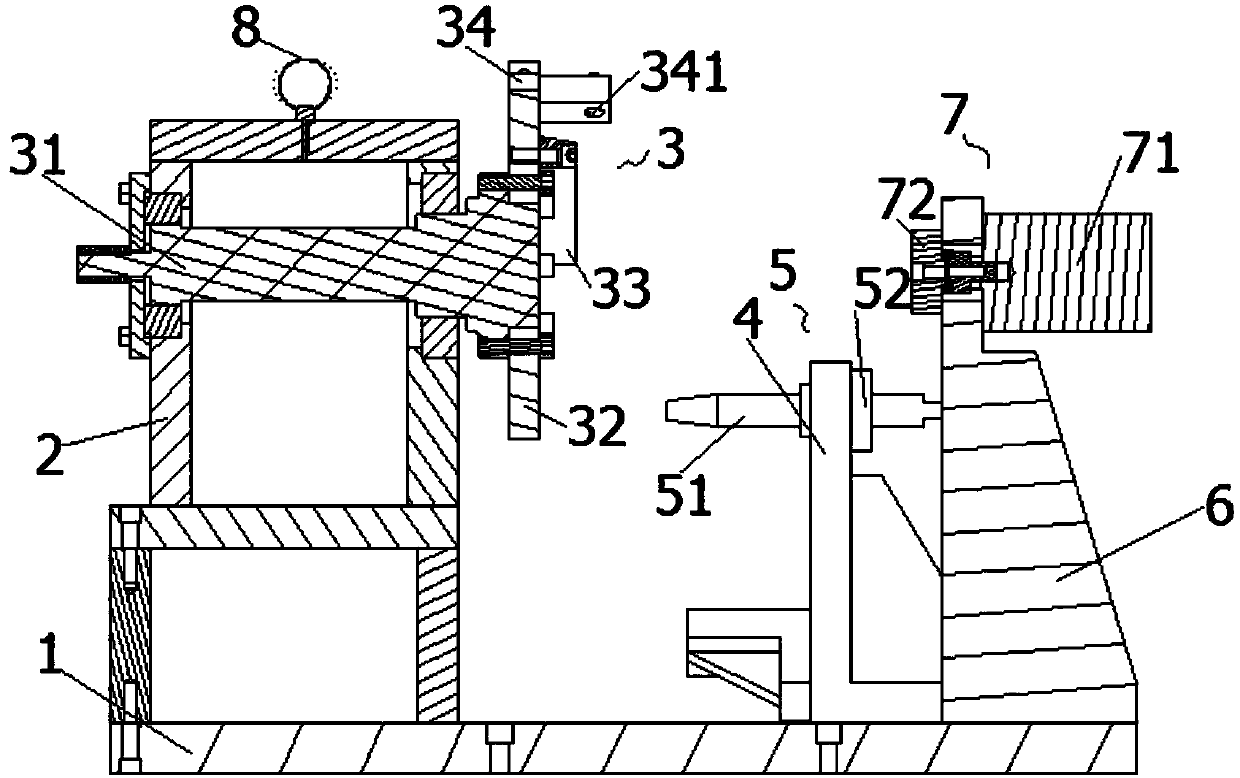

[0035] Such as figure 1 - Figure 5 As shown, the embodiment of the present invention provides a fixture, including a base 1, a fixing device and at least two positioning devices; the fixing device includes a first bracket 2 fixed on the base 1, and the first bracket 2 is pivotally connected to The fixed portion 3 of the workpiece; the positioning device includes a second support 4 fixed on the base 1, the second support 4 is provided with a positioning portion 5 that can limit the rotation of the workpiece to be processed, when the workpiece to be processed and the fixed portion 3 and the positioning When the part 5 is fixedly connected, the corresponding processing surface 91 of the workpiece to be processed faces the processing part of the machine tool.

[0036] The clamp provided by the embodiment of the present invention includes a base 1, a fixing device and at least two positioning devices, wherein the first bracket 2 in the fixing device is fixed on the base 1, and th...

Embodiment 2

[0060] An embodiment of the present invention provides a machine tool, including the above-mentioned clamp, which is detachably fixed on the machine tool.

[0061] After the fixture is fixed on the machine tool by bolts, the workpiece to be processed is fixedly connected to the fixed part 3. At this time, its rotation is restricted by a positioning device to complete the fixing of the workpiece to be processed on the base 1. At this time, one of the processing surfaces 91 Facing the processing part of the machine tool, the processing part can complete the processing of the processing surface 91. After the processing is completed, the positioning device cancels the restriction on the rotation of the workpiece to be processed, and then re-completes the positioning of the workpiece to be processed on the base 1 by another positioning device. Fixed, at this moment, another processing surface 91 is towards the processing part of machine tool, and processing part can complete the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com