Profile-adjustable stretch-bending forming mold for stand column-like components of railway vehicles

A rail vehicle and stretch bending forming technology, which is applied to vehicle parts, forming tools, manufacturing tools, etc., can solve the problems of long mold manufacturing cycle, complex stress and strain changes, and poor component assembly accuracy, so as to reduce labor intensity and reduce production Cost, the effect of improving the forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

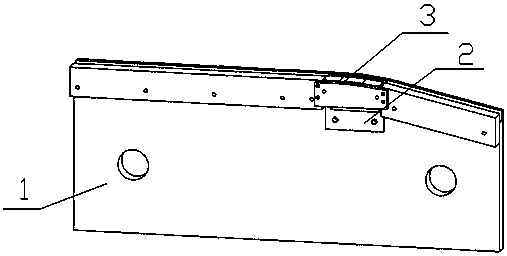

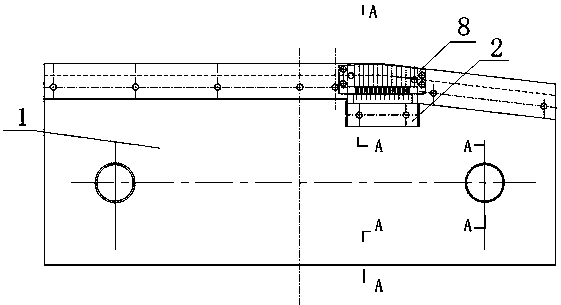

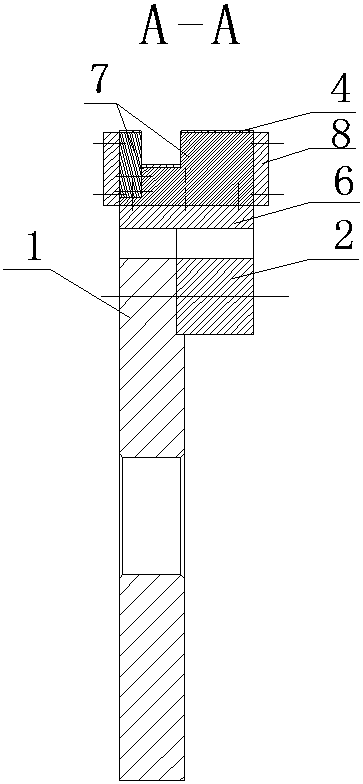

[0022] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0023] see Figure 1 to Figure 7 As shown, the tension-bending forming die for rail vehicle column members with adjustable profile does not need to modify the profile, just adjust the profile, and can also adapt to the forming of different parts, which can greatly reduce the cost, and the cycle is short. obvious. The invention simultaneously solves defects such as wing edge warping, cross-section opening, and side wall bending that occur in the stretch-bending forming process of rail vehicle column members, improves work efficiency, and reduces production costs. Including mold main body 1, support block 2, backing plate 4, end baffle plate 5, bottom plate 6, base body 7, side baffle plate 8, adjusting stud 9, locking screw 10, said mold main body 1 is fixed on the stretch bending machine , the adjustable profile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com