Vibratory sieving device for bauxite

A vibrating screening, bauxite technology, applied in the direction of sieve, solid separation, grid, etc., can solve the problem of high fine dust concentration, and achieve the effect of reducing fine dust concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further detailed explanation through specific implementation mode below:

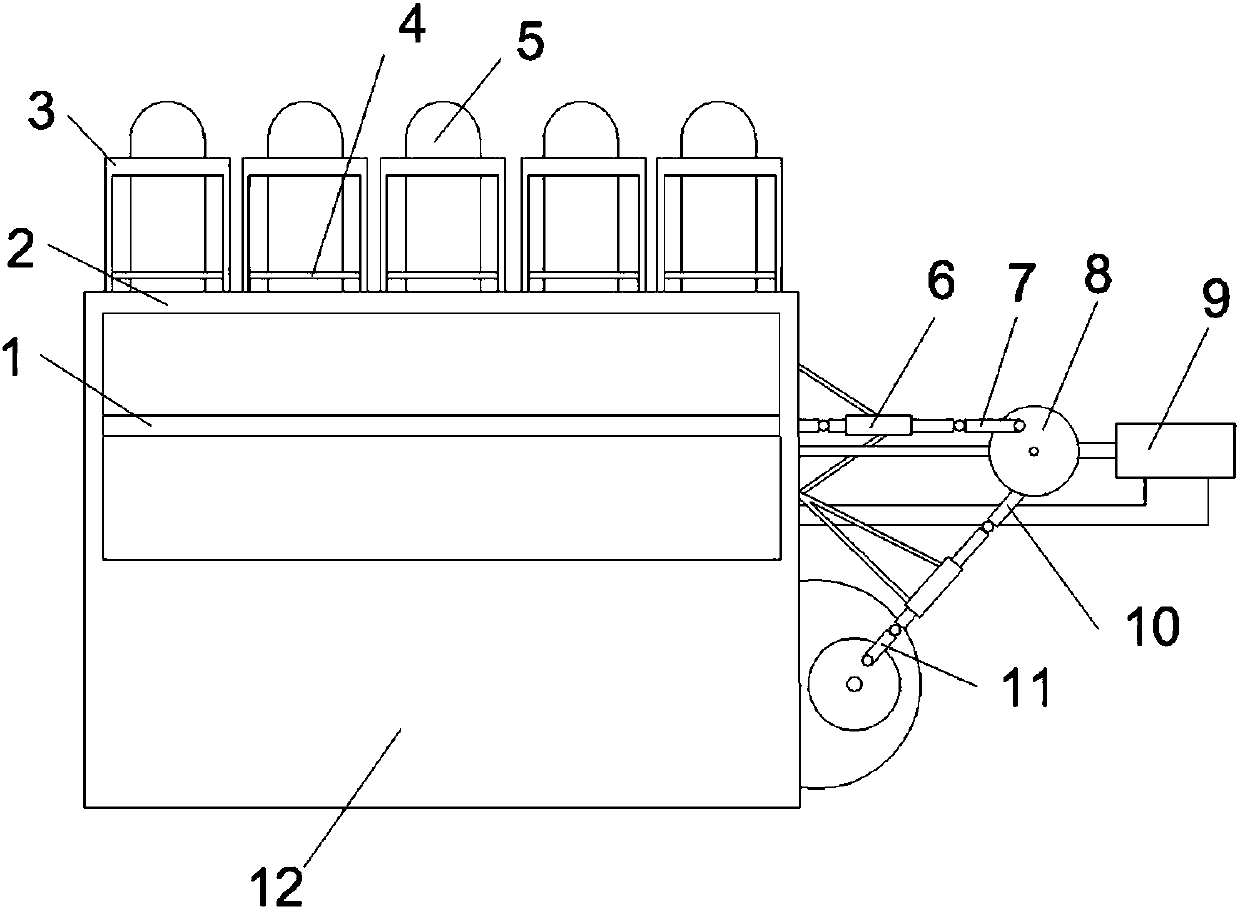

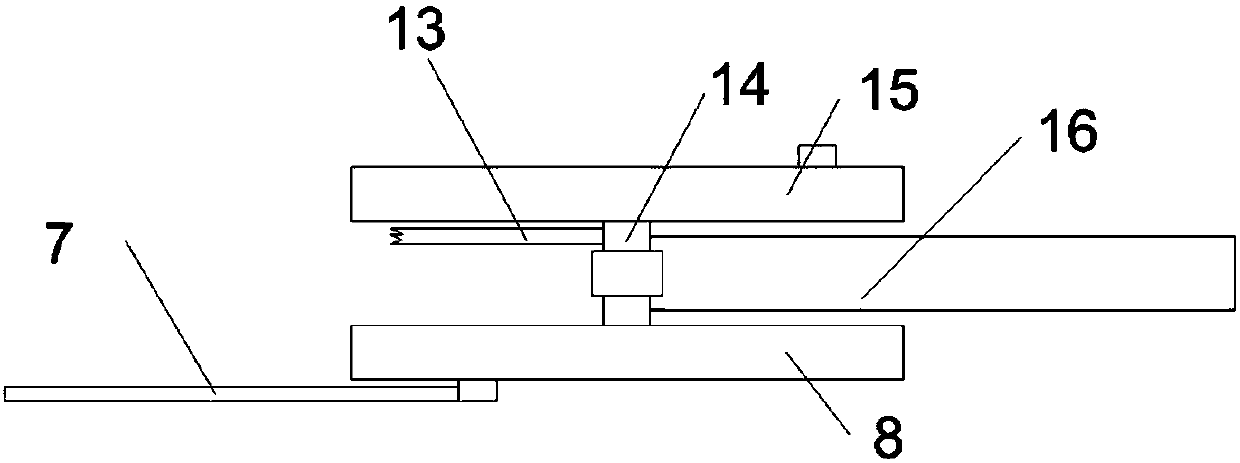

[0016] The reference signs in the drawings of the description include: rectangular screen 1, connecting beam 2, vibrator 3, iron ring 4, bag filter 5, orientation sleeve 6, left connecting rod 7, left wheel 8, motor 9, right connecting rod 10, depression bar 11, base 12, connecting arm 13, transmission shaft 14, right wheel 15, driving helical gear 16.

[0017] The embodiment is basically as attached Figure 1~2 Shown: a vibration screening device for bauxite, including a rectangular base 12 and a power system, a layer of rectangular screen 1 is installed directly above the base 12, a support arm is connected between the rectangular screen 1 and the base 12, and the support arm is vertical It is connected to the four corners of the base 12, and a chute is provided between adjacent support arms, and the chute is slidably connected with the rectangular screen 1.

[0018] The power system includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com