System for peeling non-peeled walnuts

A walnut peeling and walnut technology is applied in the field of green walnut peeling systems, which can solve the problems of difficulty in walnuts, low walnut peeling efficiency, easy contamination of colored walnuts, etc., and achieves the effect of reducing post-processing procedures and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

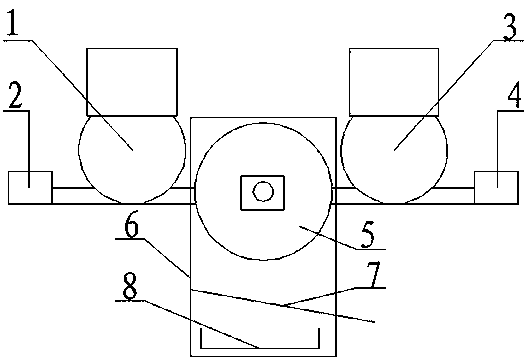

[0029] As shown in the figure, the specific implementation method is as follows:

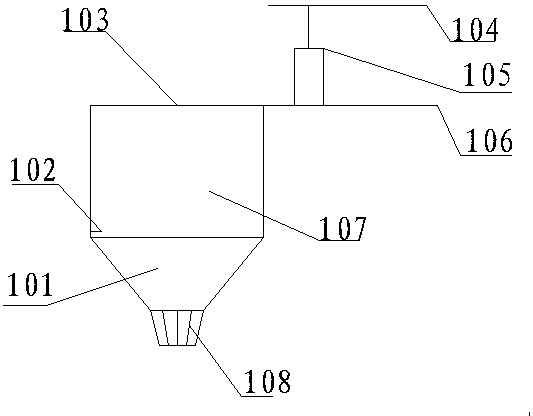

[0030] A green walnut peeling system, including a peeling system, a cleaning system, a drying system and a selection system,

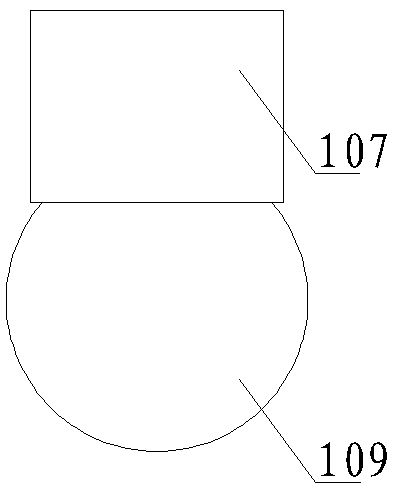

[0031] The peeling system includes a first box body 6, a peeling mechanism 5 is arranged in the first box body 6, and the peeling mechanism 5 includes a peeling box 504, and a pair of symmetrically distributed feeding ports are arranged on the peeling box 504 , the feeding port is respectively the first feeding port 501 and the second feeding port 503, a skinning roller 505 is arranged in the peeling box 504, and the peeling roller 505 is arranged in the peeling box 504 by rotating shaft 502, to remove The distance between the skin roller 505 and the inner wall of the peeling case 504 is greater than the minimum outer diameter of the walnut after peeling, and the distance between the peeling roller 505 and the inner wall of the peeling case 504 is less than the maximum o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com