Power conversion system and common mode voltage suppression method thereof

A technology for converting system and common-mode voltage, which is applied in the field of power conversion system, can solve the problems of smaller power density, larger size of isolation transformer, and lower reliability, so as to reduce ground voltage, suppress common-mode voltage, reduce The effect of small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0102] Herein, the detailed content and technical description of the present invention will be further described with a preferred embodiment, but it should not be construed as a limitation to the implementation of the present invention.

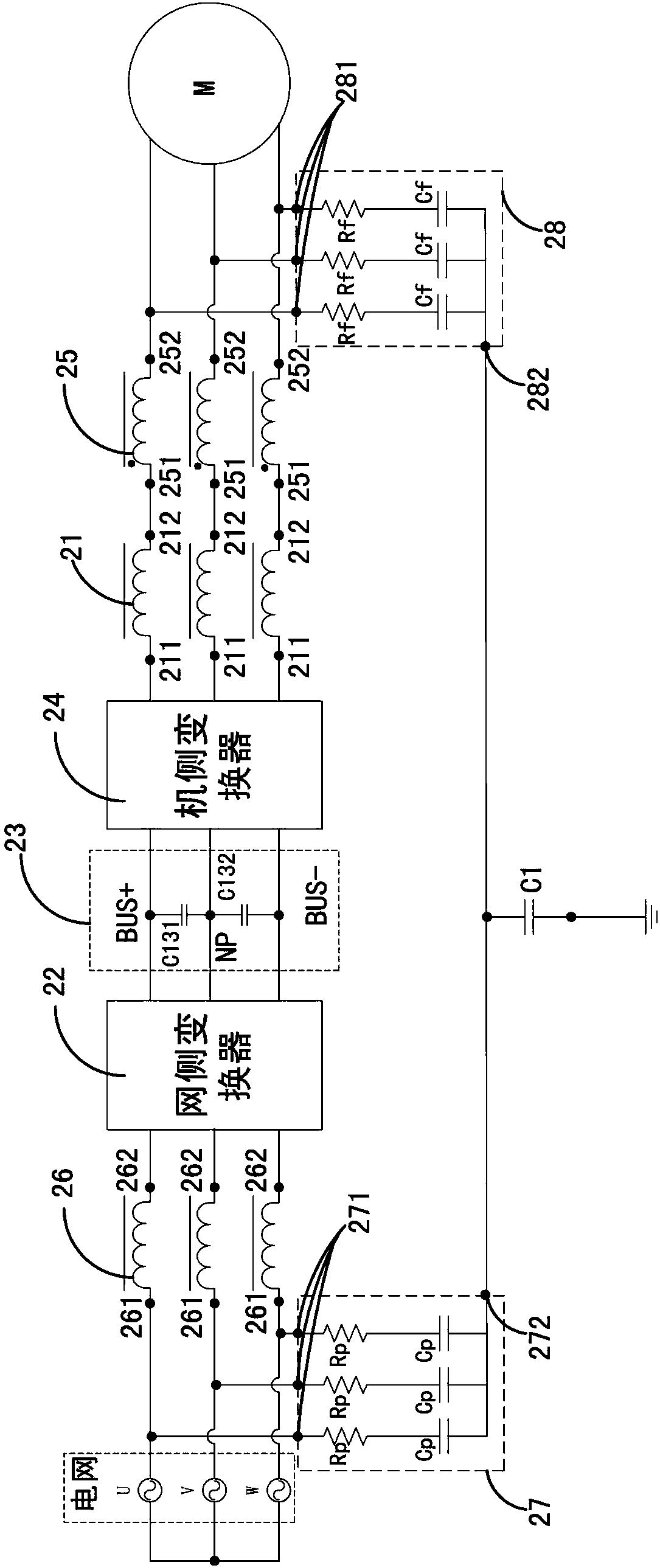

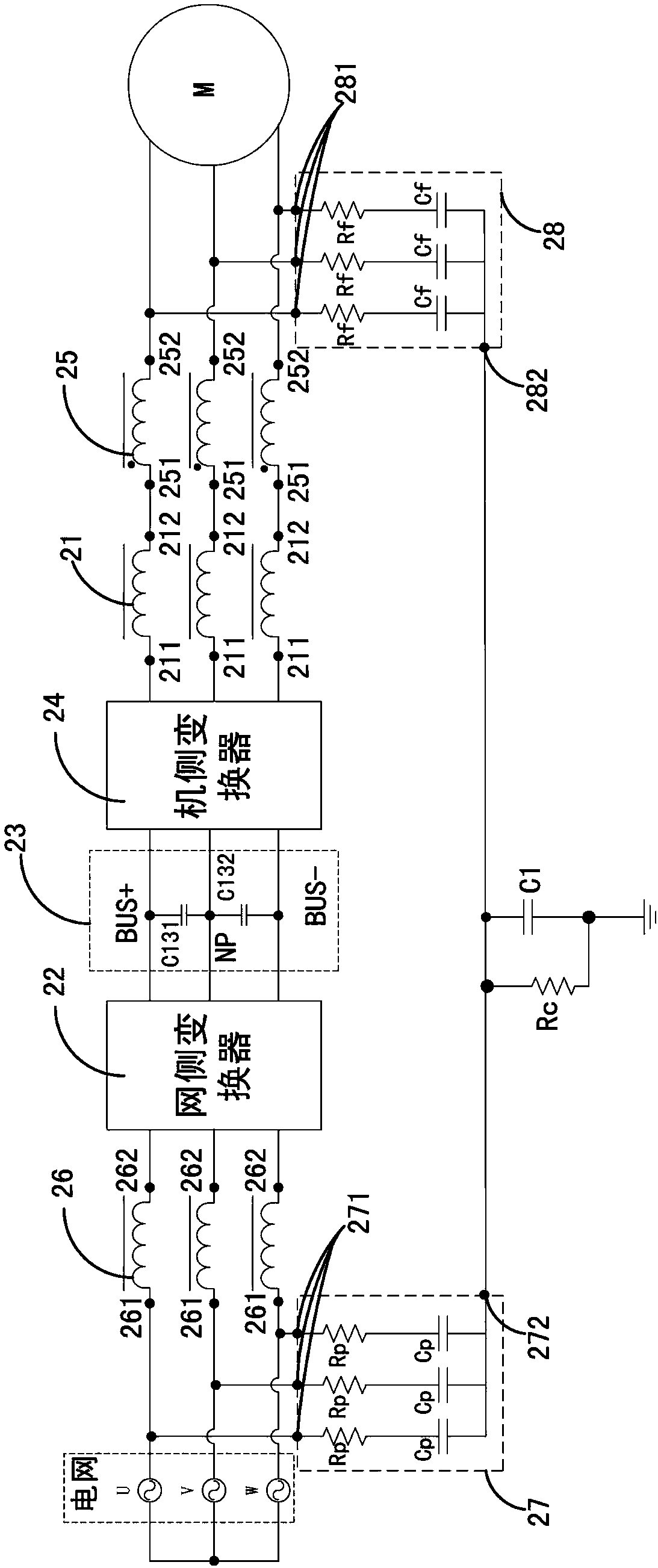

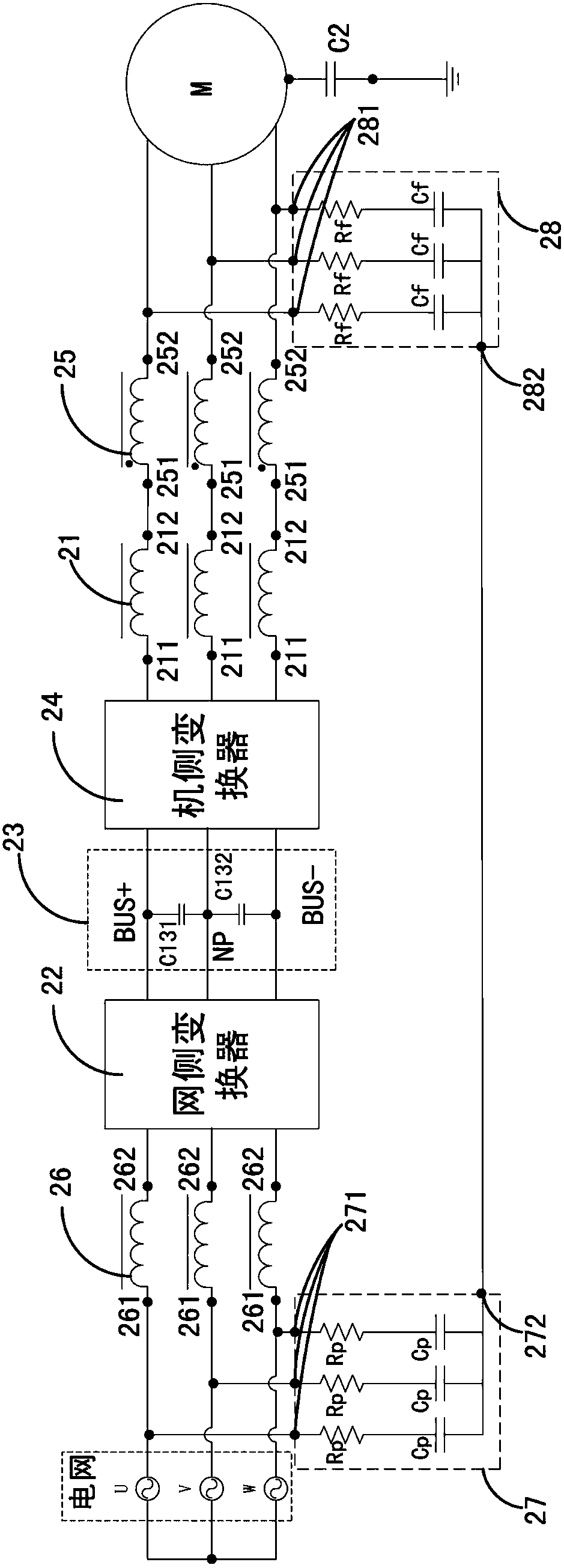

[0103] See figure 1 , figure 1 It is a schematic structural diagram of the power conversion system according to the first embodiment of the present invention. like figure 1 As shown, the power conversion system of the present invention includes a first reactor 21, a grid-side converter 22, a bus capacitor 23, a machine-side converter 24, a second reactor 25, a third reactor 26, a first filter network 27, a first Two filter networks 28 and the motor M; the bus capacitor 23 is electrically connected between the grid-side converter 22 and the machine-side converter 24. In this embodiment, the bus capacitor 23 may include a first bus capacitor C131 and a second bus capacitor C132 , and one end of the first bus capacitor C131 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com