Recycled-type rubbish landfill site and landfill method

A landfill and garbage technology, applied in the field of environmental sanitation engineering, can solve problems such as difficult to find landfill sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

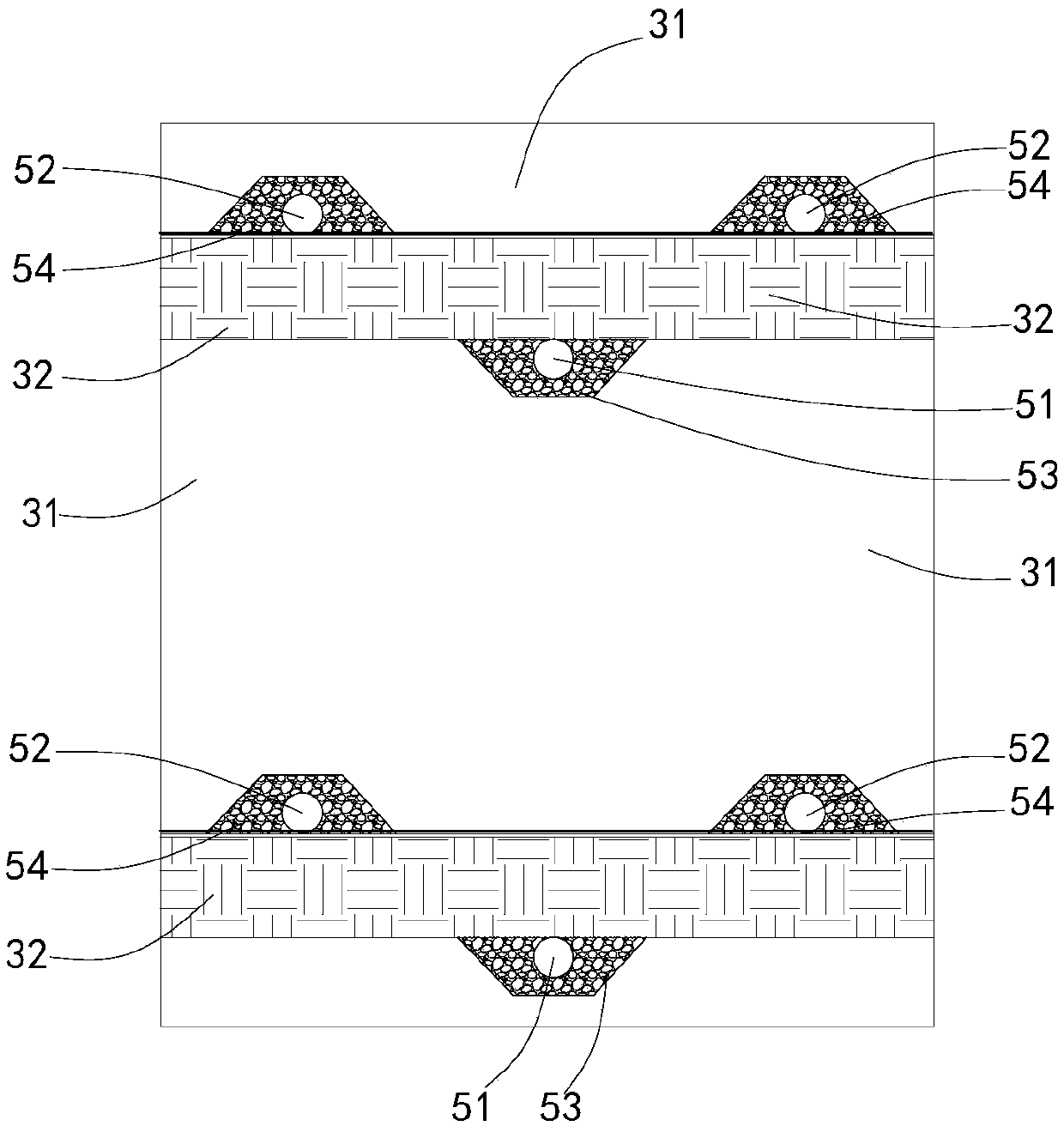

[0052] Embodiment 1, the aerobic treatment includes: during the garbage landfill process in the garbage landfill area 3, the first ventilation flower tube 5 is buried horizontally in the garbage dump body, and the aerobic equipment in the equipment management area 2 passes through the garbage after landfill. Inject air or pump air into the first ventilation flower tube 5 to realize the aerobic function. By setting the first ventilation flower tube arranged horizontally, gas can be injected or pumped into the first ventilation flower tube through aerobic setting to increase the oxygen content in the garbage dump, and at the same time, the extracted gas will be discharged after being treated up to the standard, so as to speed up the garbage dump. Breakdown of waste in the body.

[0053] The first ventilation flower tube 5 of this embodiment is preferably made of PE material, and the diameter of the pipe is 50mm-200mm, and the size of the pipe diameter can be selected according t...

Embodiment approach 2

[0060] Embodiment 2, such as Figure 9 As shown, the aerobic treatment in this embodiment includes: after the landfill area 3 completes the landfill, open a vertically arranged gas circulation well 6 on the garbage dump body, and insert at least one gas circulation well 6 into the gas circulation well 6 A second ventilation floral tube 8, after the garbage is landfilled, injects or pumps air into the second ventilation floral tube 8 through the aerobic equipment in the equipment management area 2 to realize the aerobic function. By setting the gas circulation well, the aerobic function in the vertical direction of the garbage dump can be realized.

[0061] The aerobic treatment in this embodiment specifically includes: Figure 9 As shown, after the garbage landfill in the garbage landfill area 3 is completed, the gas circulation well 6 is opened on the garbage dump body by mechanical drilling, so that the depth of the gas circulation well 6 is smaller than the depth of the ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com