A Multi-camera Calibration and Parameter Optimization Method Based on Common Tangent Line of Sphere Projection

An optimization method and common tangent technology, applied in the field of computer vision, can solve problems such as lack of geometric meaning of parameters, tedious and inefficient, and susceptible to noise, and achieve high calibration accuracy, overcome cumbersome and inefficient, and optimize camera parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The technical solution of the present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings.

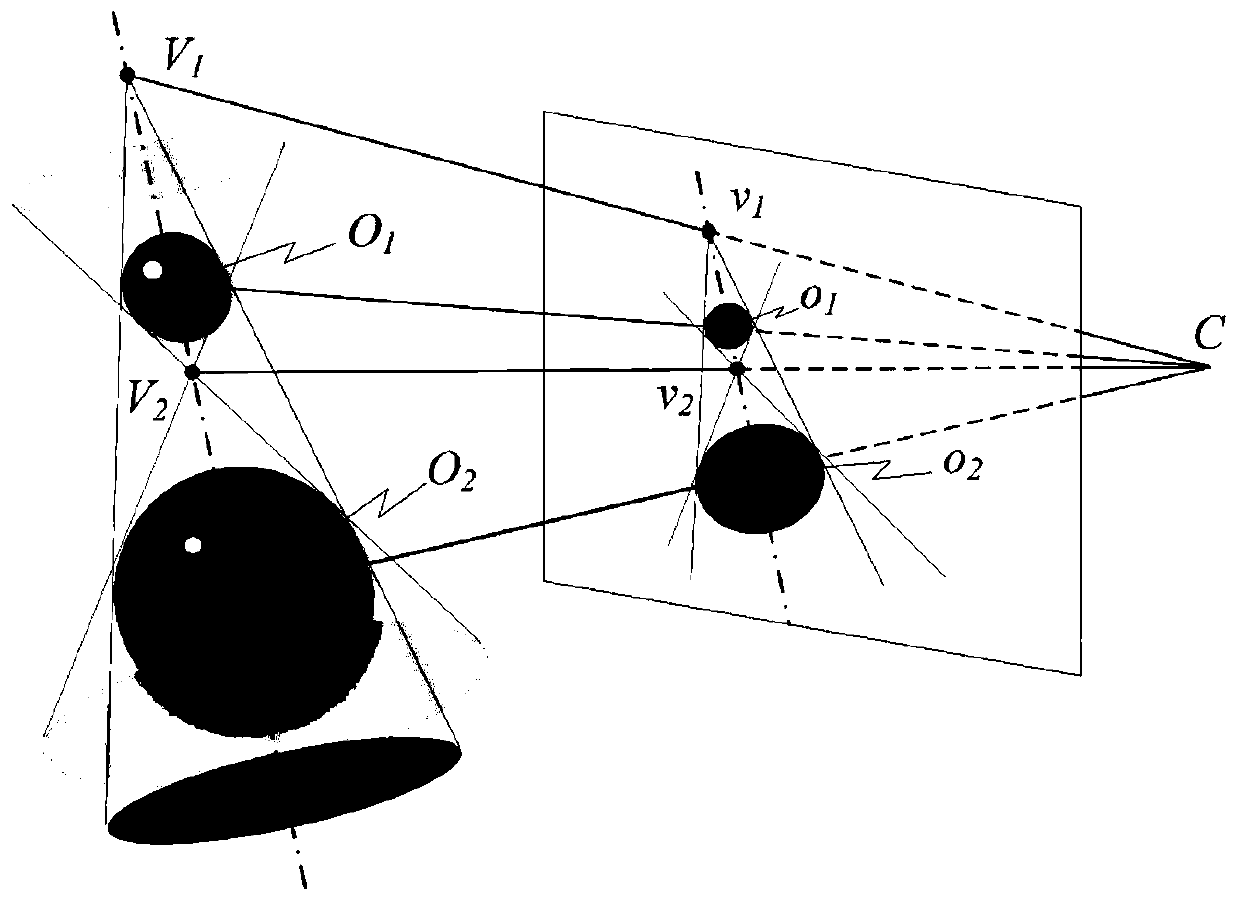

[0056] A multi-camera calibration and parameter optimization method based on the common tangent of sphere projection, including two parts: multi-camera calibration and parameter optimization. The specific steps are as follows:

[0057] 1. Contour extraction and curve fitting:

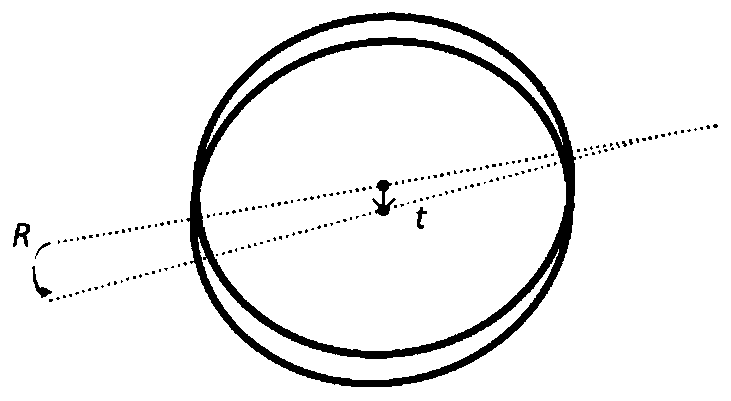

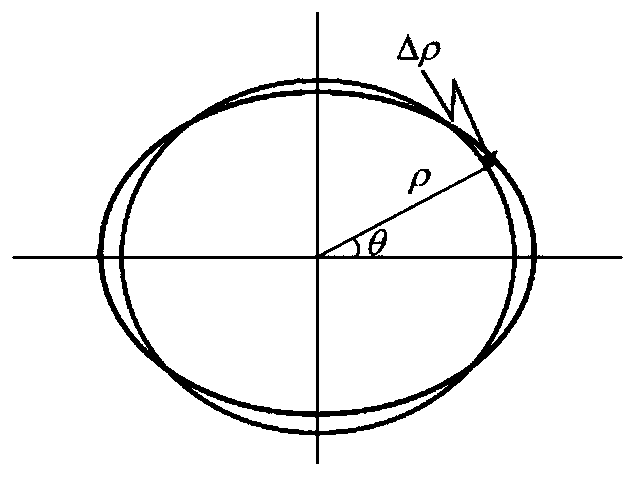

[0058] Place at least 3 calibration spheres (with known radii) under the common field of view of the camera, and ensure that each camera can capture the calibration sphere without occlusion. For each image, the Canny operator is used to extract the contour, and the least squares ellipse fitting method is used to perform curve fitting on the projected outer contour of the calibration sphere to obtain the outer contour curve C of the sphere projection.

[0059] 2. Determine the projection of the center of the sphere by the common tangent:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com