A Construction and Method of Segmental Connection of Prefabricated Assembled Bridge Piers

A prefabricated assembly and segment technology, applied in the erection/assembly of bridges, bridges, bridge construction, etc., can solve problems such as weak connection of prefabricated pier segments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

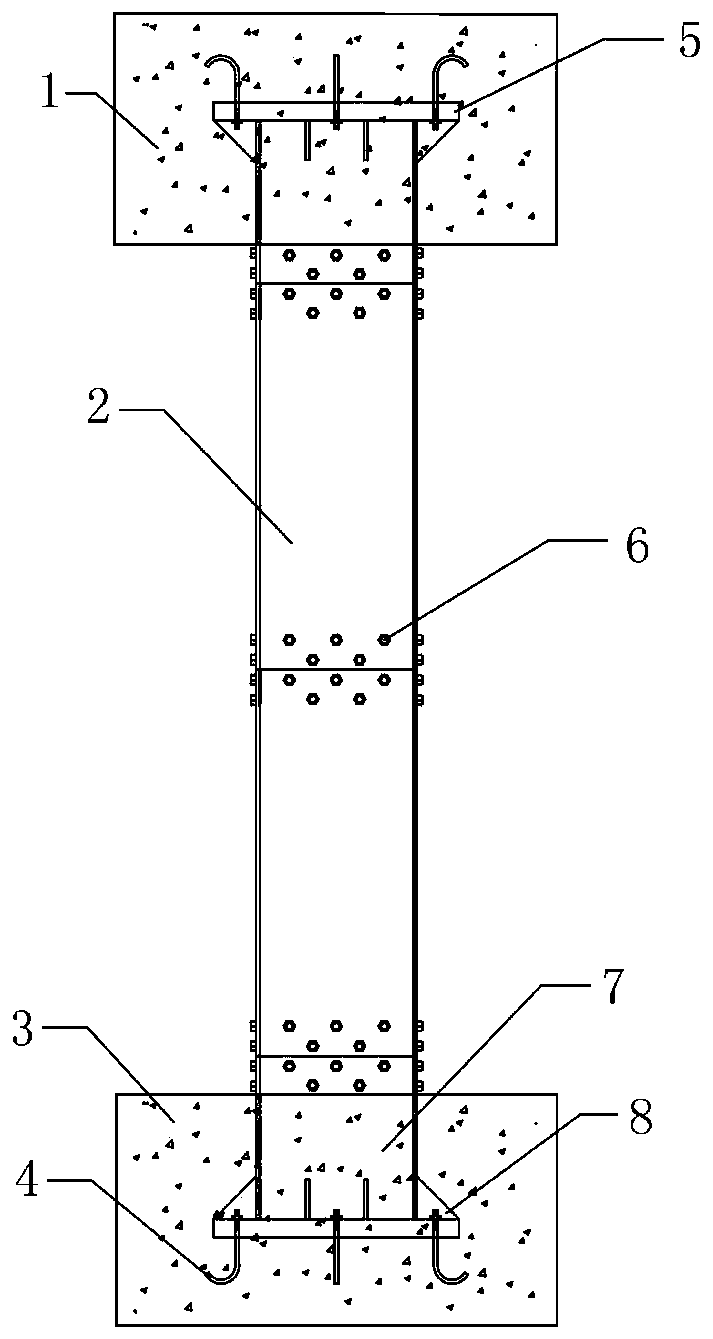

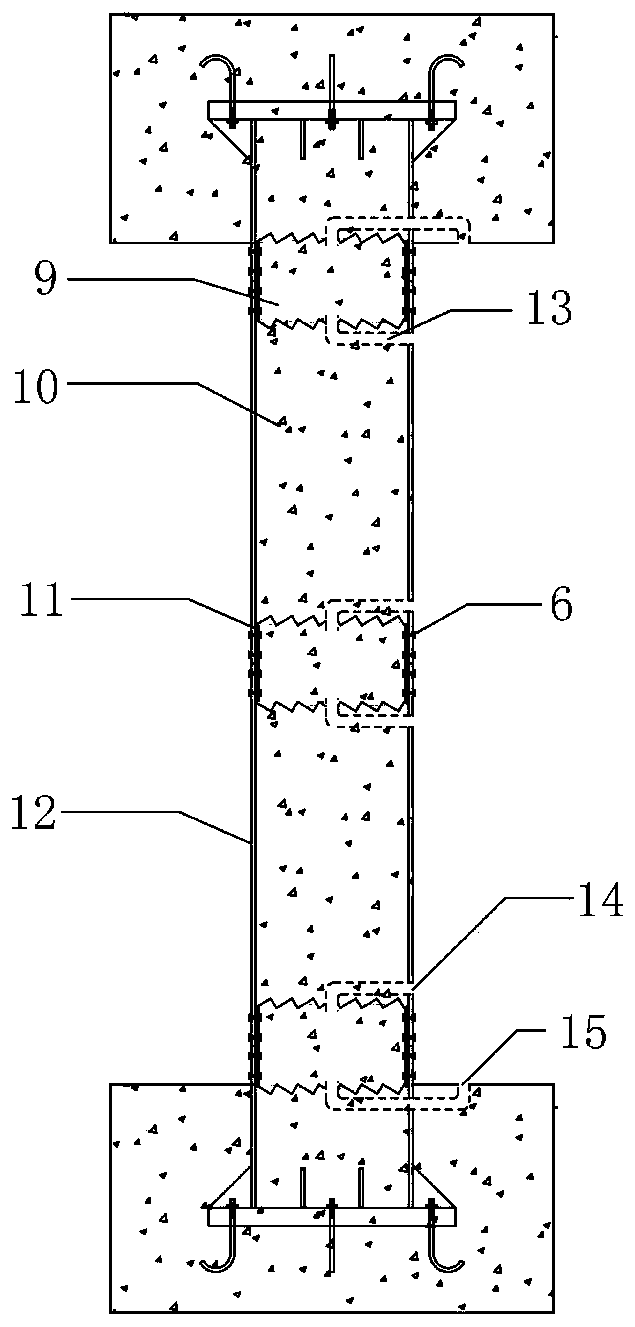

[0028] The following is attached figure 1 — attached Figure 7 The specific embodiment of the present invention is further described:

[0029] A construction and method for segmental connection of prefabricated assembled bridge piers, step 1: prepare pre-embedded segment 7, prefabricated steel tube concrete segment 2 and inner sleeve connecting steel tube 11 in a factory, the specific steps are as follows:

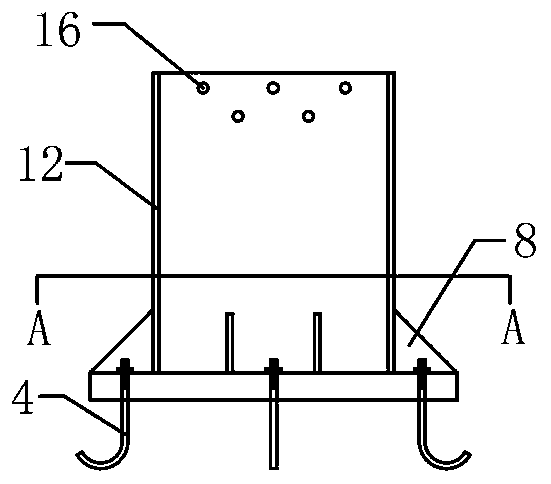

[0030] 1 First cut the steel plate into the target size, and then open the bolt holes 16, the UHPC pouring inlet 15, and the UHPC pouring outlet 14 at the corresponding positions.

[0031] 2 The pre-embedded segment 7 is composed of a prefabricated segmental steel pipe 12, an end plate 5, a stiffener 8 and an anchor bolt 4. The prefabricated steel pipe segment 12 is obtained by welding steel plates. The prefabricated steel pipe segment 12 is welded to the end plate 5 , and the stiffeners 8 are welded around the prefabricated steel pipe segment 12 and the end plate 5 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com