Trichromatic fabric dyeing and finishing device

A technology of three primary colors and fabrics, which is applied in the processing of textile material equipment configuration, textile material processing, liquid/gas/steam textile material processing, etc., and can solve problems such as single process, low product added value, and monotonous product color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

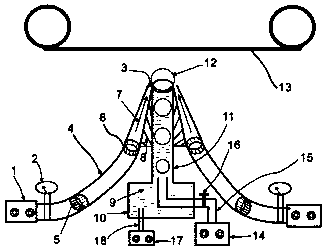

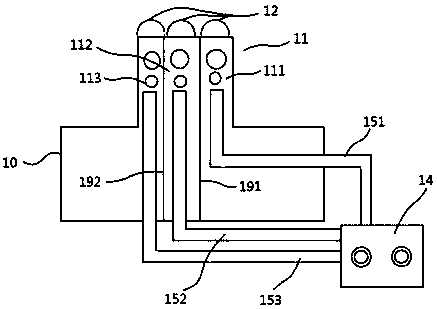

[0021] Such as figure 1 As shown, a three-primary-color fabric dyeing and finishing device includes a dye solution tank 10 and a cavity bubble emission tube 11 arranged above the dye solution tank 10; it also includes a bubble generator 14, and the bubble generator 14 is arranged outside the dye solution tank 10 , the bubble generator 14 stretches into the inside of the cavity bubble launch tube 11 through the air guide tube 15, and the openings of the air guide tube 15 and the cavity bubble launch tube 11 are all upward; the two sides of the cavity bubble launch tube 11 are provided with air flow injection tubes 4. The airflow injection pipe 4 is connected to the airflow generator 1, and the airflow injection pipe 4 extends from the airflow generator 1 to the edge of the upper end of the cavity bubble emission pipe 11; the airflow injection pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com