Hot cell crane

A technology of hot room crane and shielding room, which is applied in the direction of load hanging components, walking mechanism, transportation and packaging, etc., can solve problems such as shortening of service life, and achieve the effect of reducing service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

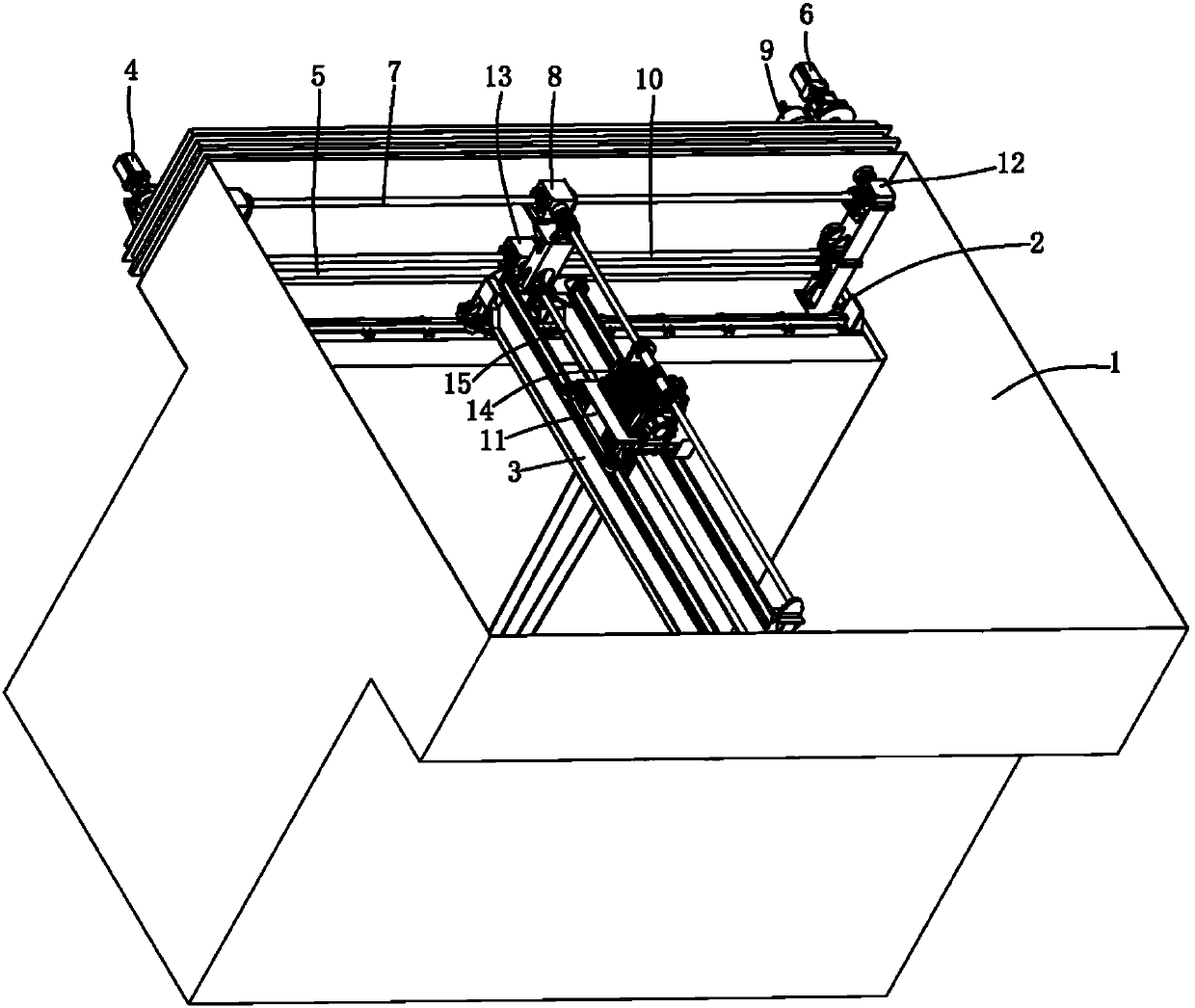

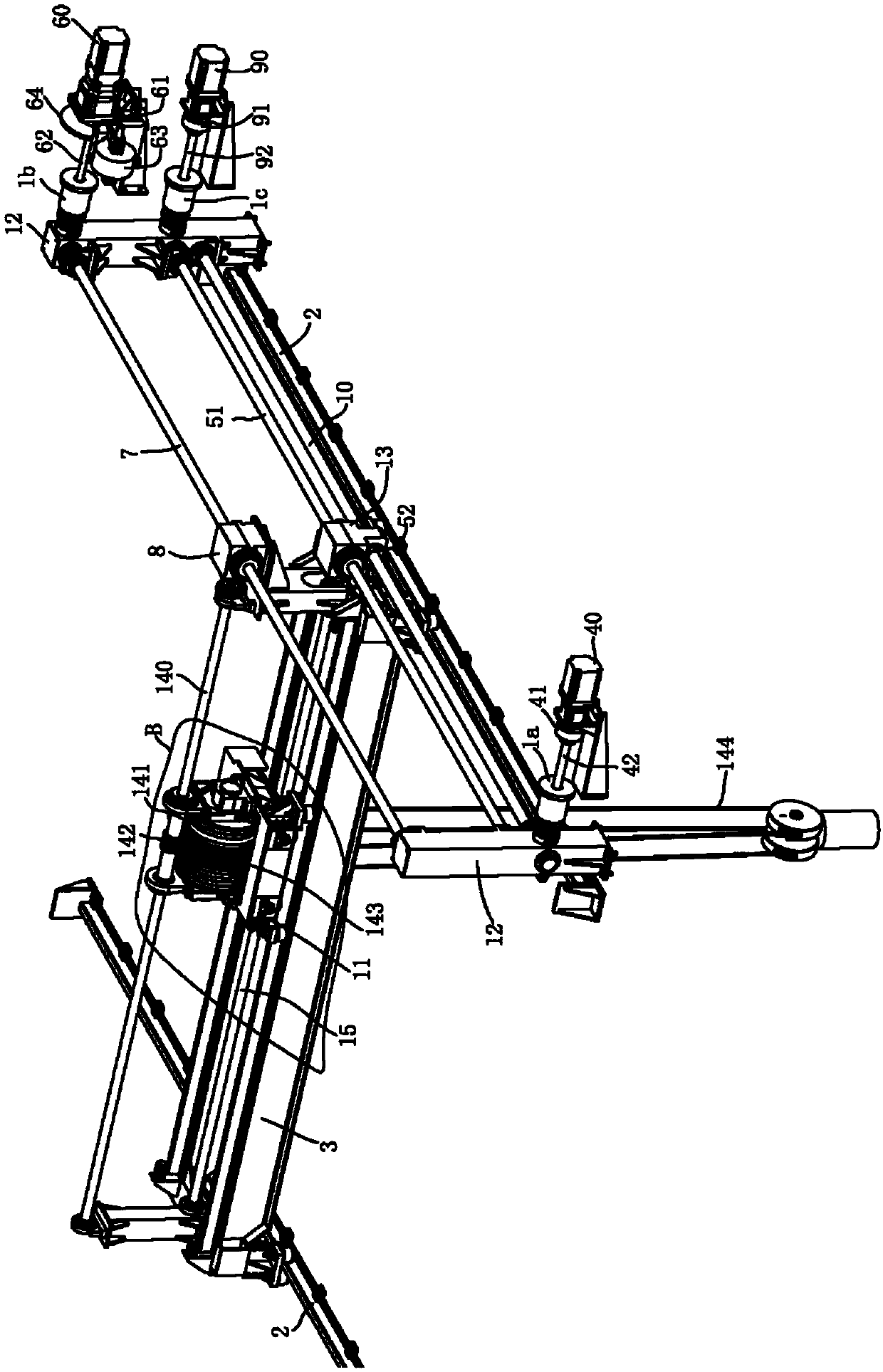

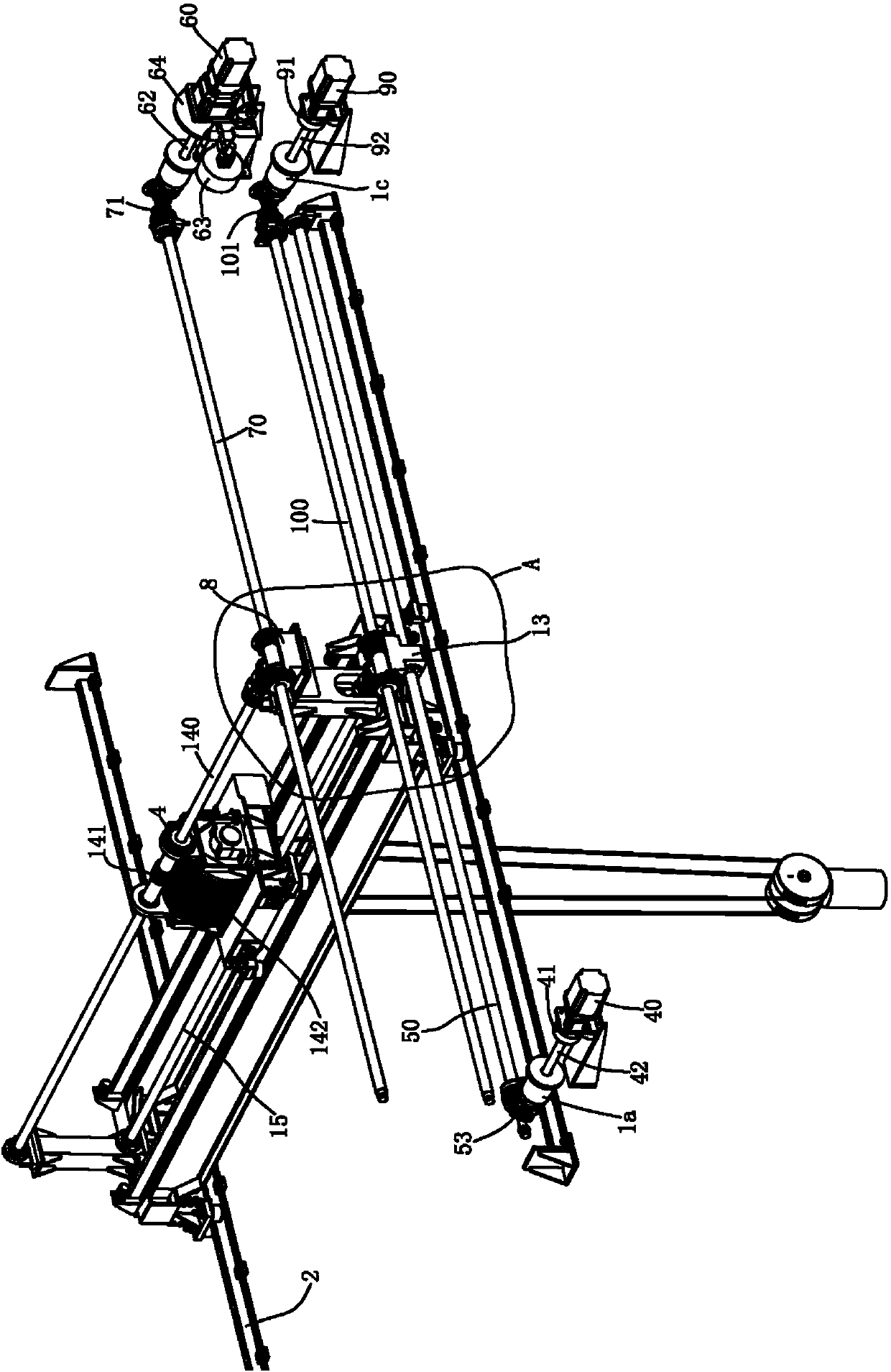

[0062] The hot chamber crane includes a shielding room 1, in which a horizontal guide mechanism 2 arranged horizontally along the shield 1 and a longitudinal guide mechanism 3 arranged longitudinally along the shielding room 1 are provided in the shielding room 1, and both ends of the longitudinal guide mechanism 3 are respectively slidingly fitted On the horizontal guide mechanism 2, it also includes:

[0063] A first linear transmission mechanism 5 arranged inside the shielding room 1 and connected to the longitudinal guide mechanism 3, and a first driver 4 arranged outside the shielding room 1, the output end of the first driver 4 and the first linear transmission mechanism 5 is connected, the first linear transmission mechanism 5 is driven by the first driver 4 to make the longitudinal guide mechanism 3 slide along the transverse guide mechanism 2;

[0064] A second driver 6 arranged outside the shielding room 1 and a first torque transmission mechanism 7 arranged inside the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com