90-degree reversing mechanism

A technology of reversing mechanism and material pushing mechanism, which is applied in the direction of conveyor objects, transportation and packaging, etc. It can solve the problems of complicated process and difficult processing of the bottle feeding screw, and achieves a small space occupation, low cost and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

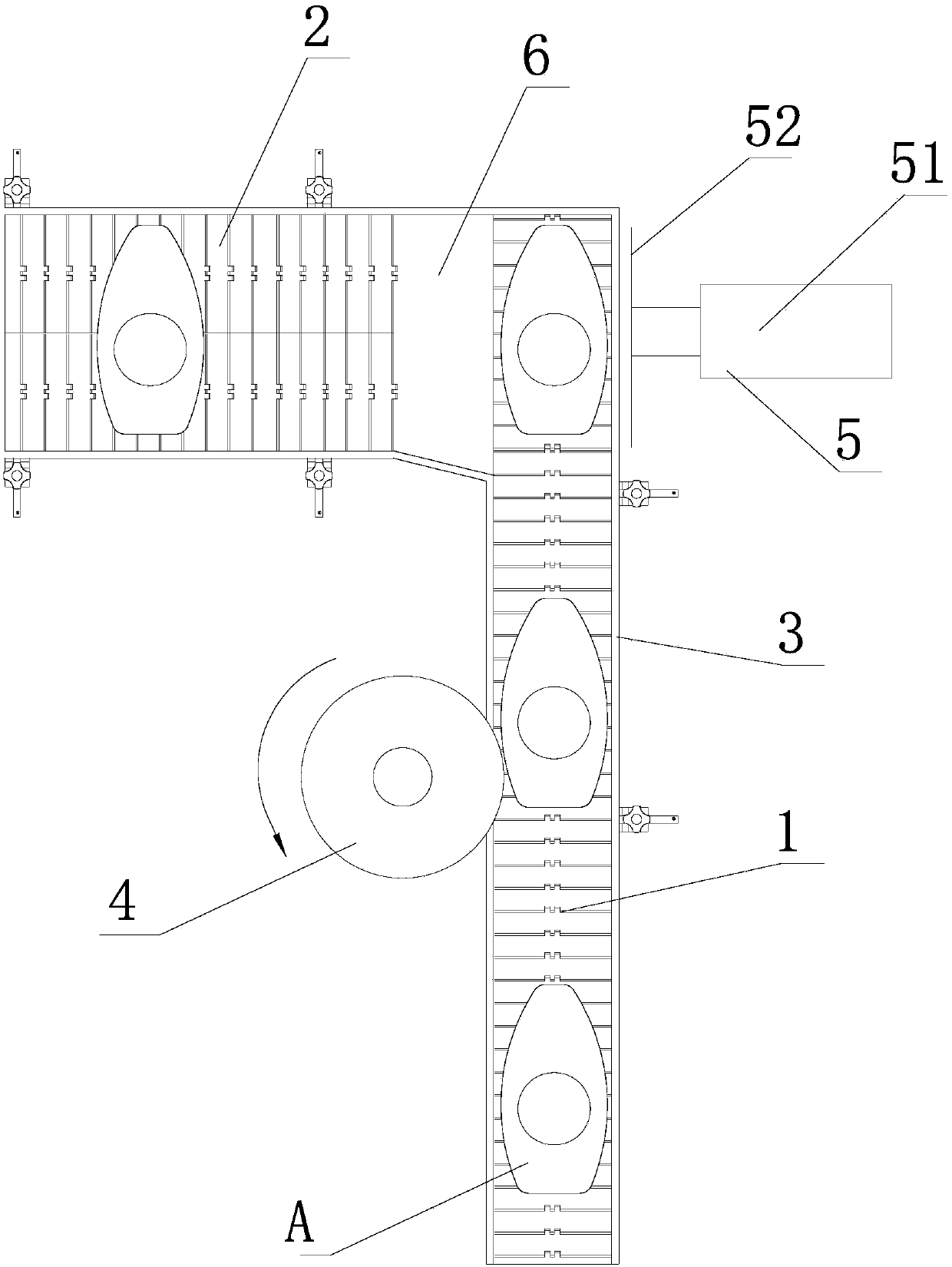

[0017] Such as figure 1 As shown, the embodiment of the present invention provides a 90-degree reversing mechanism, which includes a first conveyor belt 1 and a second conveyor belt 2, and the first conveyor belt 1 and the second conveyor belt 2 are distributed at a 90-degree angle. , both sides of the first conveyor belt 1 are equipped with a guide guard 3, and one side of the first conveyor belt 1 is provided with an equidistant wheel 4, and the equidistant wheel 4 is used to press the material A to the guide guard 3. The bottom of a conveyor bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com