Device capable of removing micro-plastic particles in water in ditch water inlet type seawater culture pond

A technology for mariculture and microplastics, applied in fish farming, separation methods, filtration and separation, etc. It can solve the problems of inability to remove microplastic particles, protect human health, reduce the frequency of filter replacement or flushing, combined installation and Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further described in conjunction with the following examples.

[0020] It should be noted that the following content is a further detailed description of the present invention in conjunction with specific embodiments, but it cannot be determined that this embodiment is limited thereto. Various improvements or optimizations are made on this basis, and these improvements or optimizations fall within the protection scope of the present invention.

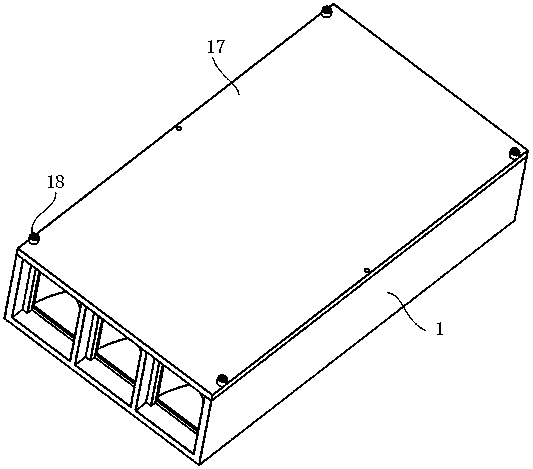

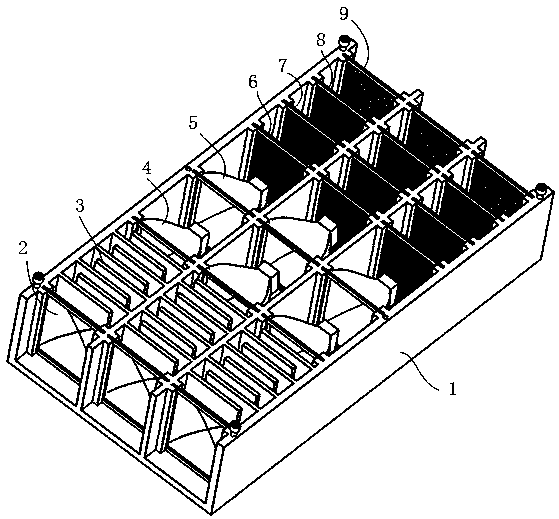

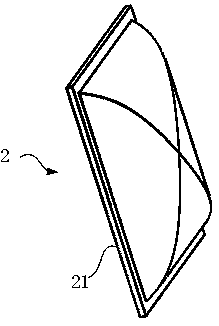

[0021] A device capable of removing microplastic particles in the water body of a ditch-inlet mariculture pond, comprising a filter box 1 embedded in the ditch and not submerged by the water flow, the filter box 1 includes two side plates 12, the Two side plates 12 are connected to one bottom plate 13, two partitions 14 are connected to the bottom plate 13, and the partitions 14 evenly divide the filter box 1 into three filter chambers 11; The inner side of the side plate 12 and both sides of the partit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com