Filter element with high-assimilative-capacity structure

A technology of capacity and filter elements, which is applied in the field of filter elements with a new type of high dirt-holding capacity structure, can solve the problems of non-reusable, etc., and achieve the effect of large filtration area, high dirt-holding capacity, and long service time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

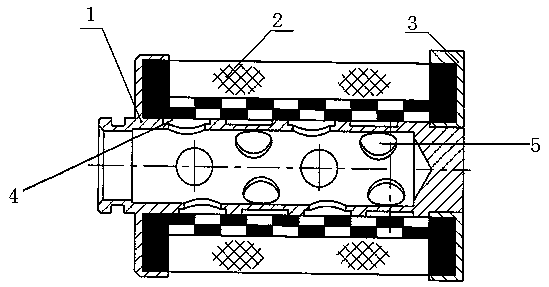

[0008] The upper frame involved in this technical solution adopts an integrated structure instead of a general-purpose split structure, adopts a small flow resistance skeleton row type instead of the original hole row method, and adopts large filter area corrugated molding instead of the original corrugated molding technology, so In the same installation space, the filter element can have a larger dirt-holding capacity, and the flow resistance of the skeleton can be reduced under the premise of ensuring the strength of the skeleton.

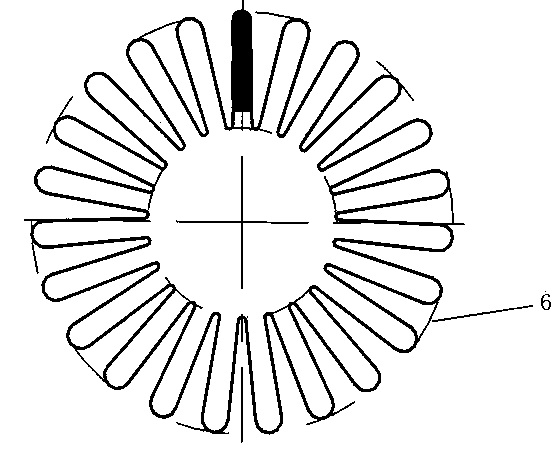

[0009] Specific examples figure 1 As shown, the upper end cover skeleton 1, the filter layer 6 and the lower end cover 3 are connected to each other by high temperature glue curing, the upper end cover and the skeleton are integrated, and the filter layer spiral groove is processed at the place where the filter layer is installed along the skeleton axis of the upper end cover 4. There are flow holes 5 evenly drilled in the spiral groove along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com