Synchronous fertilizing and seeding machine and operating method thereof

The technology of a seed metering machine and a seed metering device is applied in the field of agricultural machinery, which can solve the problems of poor emergence, burning seeds, and increasing the size of the whole machine, and achieve the effects of saving materials, simplifying the structure, and reducing the volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is further described below in conjunction with accompanying drawing:

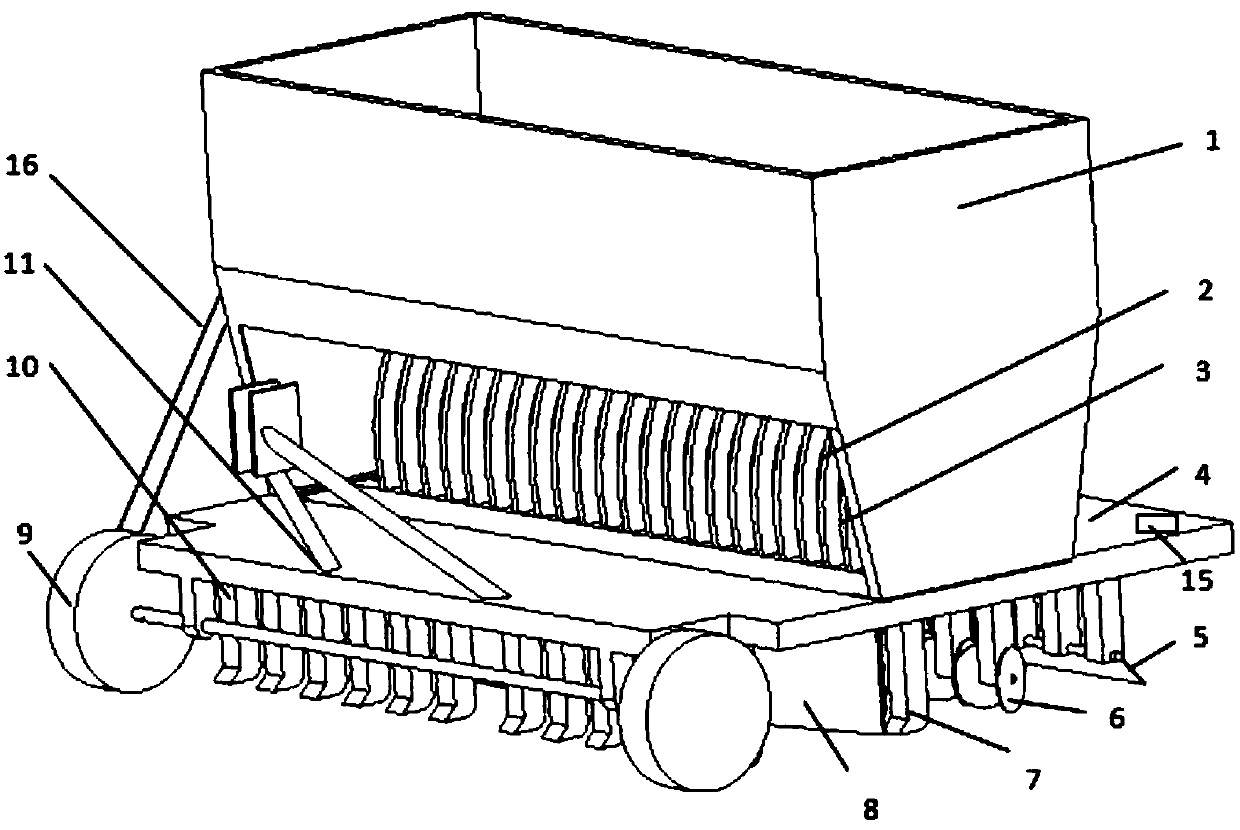

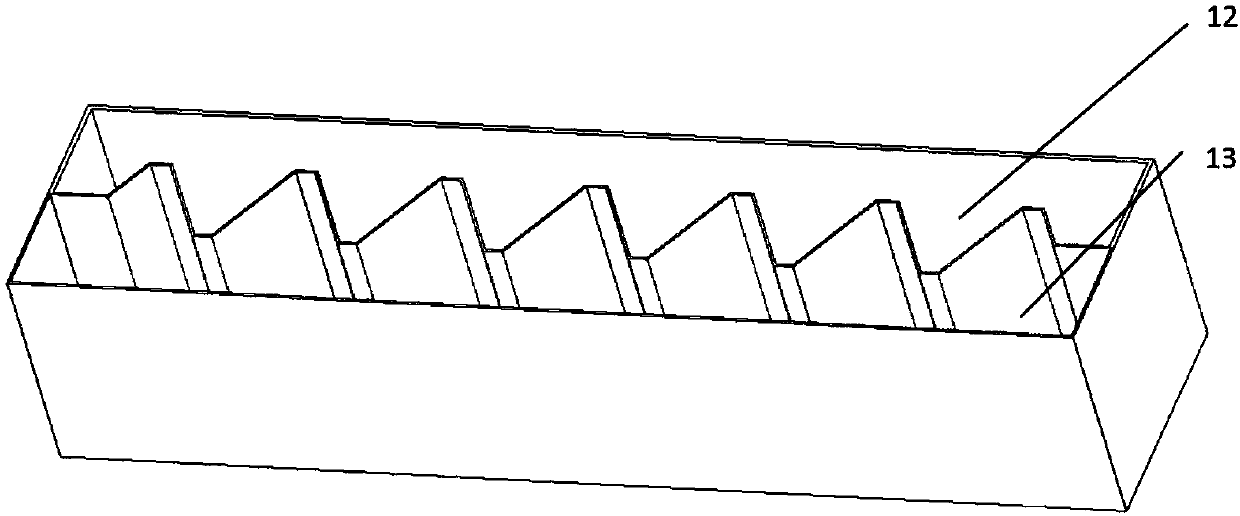

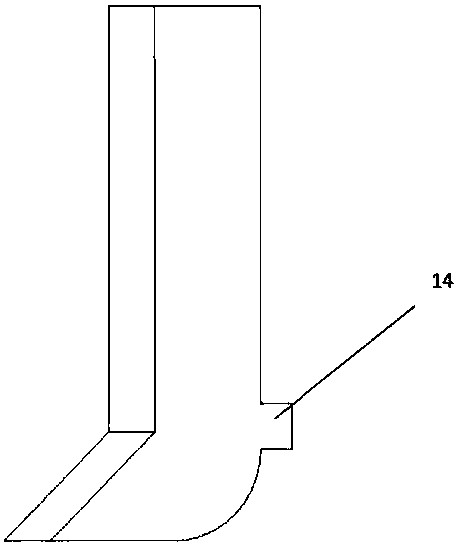

[0034] see Figure 1-Figure 3 , a synchronous fertilization and seeding machine, comprising a seed fertilizer box 1, a fertilizer discharge pipe 2, a seed discharge pipe 3, a bottom plate 4, double columbine legs 7 and a furrow plow 10; the seed fertilizer box 1 is arranged on the upper surface of the bottom plate 4, The fertilizer box 1 is provided with a partition, which separates the seed fertilizer box 1 into a fertilizer box 12 and a seed box 13; the double columbine legs 7 are formed by welding two columbine legs side by side, and a row of double columbine legs 7 is arranged in the middle of the lower surface of the bottom plate 4 The bottom of the seed fertilizer box 1 is provided with a number of fertilizer dischargers and seed metering devices, which are arranged on the same drive shaft and interlaced with each other; a double columbine leg 7 passes through a fertilizer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com