Circuit board, via hole structure for circuit board, and method for realizing via hole in circuit board

A technology of circuit boards and vias, which is applied in the fields of printed circuits, circuit devices, and printed circuit manufacturing. It can solve the problems of discontinuous impedance of the original vias, increase the reliability of system design, be simple, efficient and easy to implement, and reduce the design space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical solution and advantages of the present invention clearer, the technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

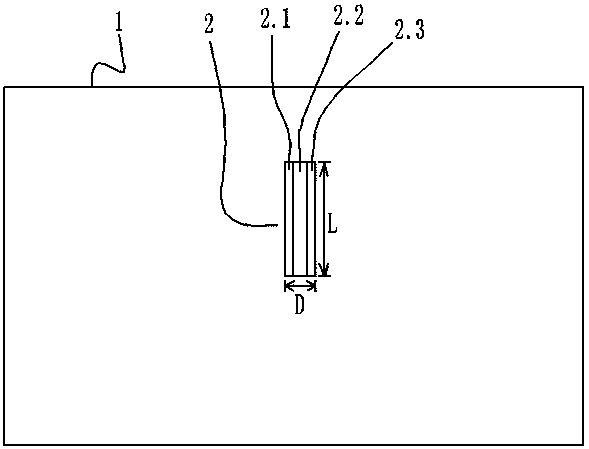

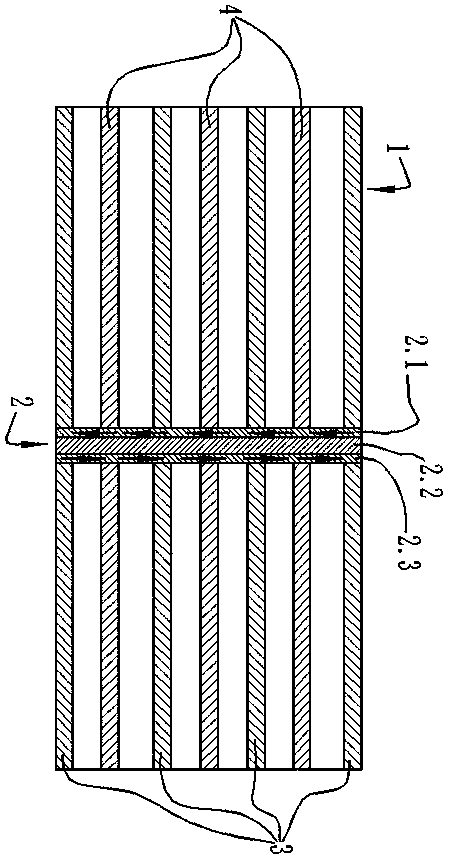

[0027] Such as figure 1 , 2 As shown, a circuit board via hole structure of the present invention is used for a circuit board 1 having a set of signal layers 3 for transmitting signals and at least one ground layer 4 for grounding, each of the signal layers 3 It is stacked with the ground layer 4 described above. The via hole structure includes an insulating medium layer 2.2 distributed along the axial direction of the via hole, a first conductive layer 2.1 for communicating with different signal layers 3 on the circuit board 1, and a first conductive layer 2.1 for communicating with the circuit board 1. The ground layer 4 is connected to the second conductive layer 2.3. The first conductive layer 2.1, the second conductive layer 2.3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com