Pile driver

A technology of piling machine and piling equipment, which is applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of long time for hanging piles, heavy weight of a single concrete pile, unfavorable concrete piles, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0038] Such as Figure 1-14 Shown is a preferred embodiment of the present invention.

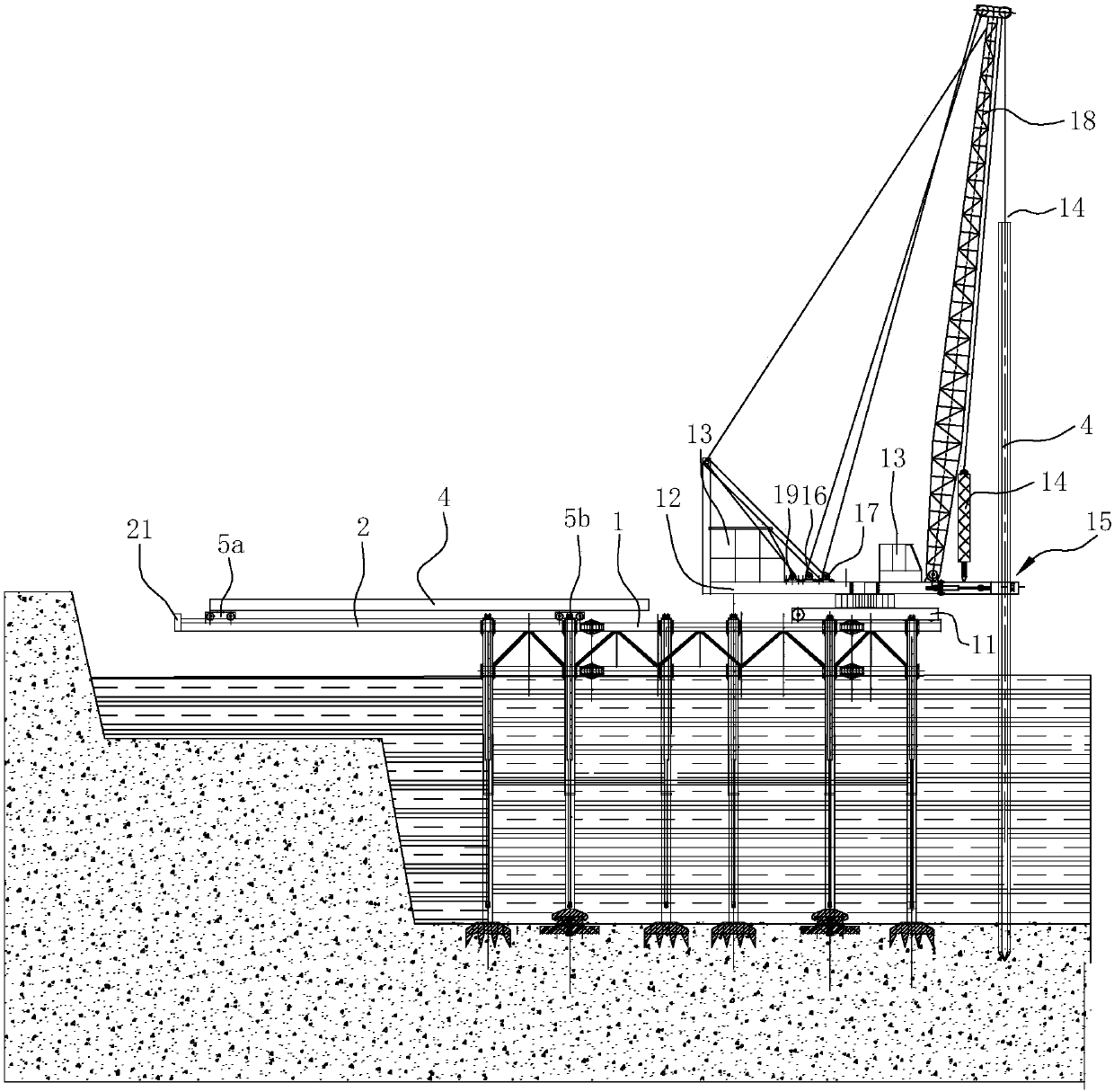

[0039] A pile driver includes a main platform 1 for installing hanging pile driving equipment, and the bottom of the main platform 1 is provided with a support structure for supporting in a river channel.

[0040] Such as Figure 1~4 As shown, the pile-hanging piling equipment includes a walking platform 11 and a rotary platform 12. The walking platform 11 is placed on the main platform 1 and can slide along the length direction of the main platform 11 and can be positioned. The rotary platform 12 is rotatably installed on the walking platform 11. The upper part can rotate 360 degrees relative to the walking platform 11, and the slewing platform 12 is provided with a control room 13 and lifting equipment for lifting the concrete pile 4 and the hydraulic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com