A kind of process method of modified HBN filled cyanate resin-based composite material

A technology of filling cyanate ester and cyanate resin, which is applied in the field of thermally conductive materials, can solve problems such as low thermal conductivity and poor thermal conductivity, and achieve the effects of improving service life, improving thermal conductivity, and increasing bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Preparation of unmodified flake hBN filled cyanate resin-based composite material with a weight fraction of 20%

[0024] In this example, 20 g of hBN without surface treatment was filled into an 80 g container of cyanate resin added with E-7 epoxy resin, and stirred for 30 min with a special stirring device at a speed of 100 rpm / min. Inject the uniformly mixed material into the mold coated with silicone oil release agent through the injection device. The cylindrical mold size is φ25.4x35mm. Place the mold with the material in a vacuum oven, vacuumize at 90-100°C for 20 minutes, solidify at 120°C / 1h+150°C / 1h+180°C / 2h+200°C / 4h, and cool naturally to room temperature. The detection needs to be cut to the required size.

[0025] Corresponding to the production of composite materials, the density and thermal conductivity are tested, and the density measured by the corresponding test is 0.92g / cm 3 ; The thermal conductivity is 0.72W / (m·K).

Embodiment 2

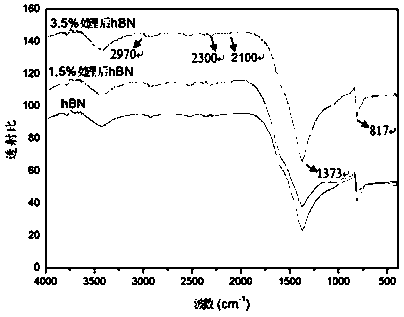

[0026] Example 2: Preparation of 20wt.% modified (1.5% coupling agent) flake hBN filled cyanate resin-based composite material

[0027] In this example, 20g flake hBN treated with 1.5wt% WD-60 type coupling agent was added to an 80g container of cyanate resin added with E-7 epoxy resin, and stirred with a special stirring device for 30min. Speed 100rpm / min. Inject the uniformly mixed material into the mold coated with silicone oil release agent through the injection device. The cylindrical mold size is φ25.4x35mm, and the square mold size is 10x10x5mm. Place the mold with the material in a vacuum oven, vacuumize at 90-100°C for 20 minutes, and after 120°C / 1h+150°C / 1h+180°C / 2h+200°C / 2h, put the resin composite mold Place it in a constant temperature device at 200°C, and apply a pressure of 1kgf to the resin composite material with a special pressurizing device to make the composite material denser. Put the pressurized mold back in a vacuum oven at 200°C, keep it warm for 1 ...

Embodiment 3

[0029] Example 3: Preparation of 20wt.% modified (3.5% coupling agent) flake hBN filled cyanate resin-based composite material

[0030] In this example, 20g flake hBN treated with 3.5% Z-6020 type coupling agent was added to 80g container of cyanate resin added with E-7 epoxy resin, stirred by magnetic stirring device for 10min, rotating speed 150rpm / min. The uniformly mixed material is injected into a mold coated with silicone oil release agent through an injection molding device. The cylindrical mold size is φ25.4x35mm, and the square mold size is 10x10x8mm. Place the mold with the material in a vacuum oven, vacuumize at 90-100°C for 20 minutes, press 120°C / 1h+150°C / 1h+180°C / 2h+200°C / 1h; after that, put the resin composite material The mold is placed in a constant temperature device at 200°C, and a pressure of 1 kgf is applied to the resin composite material with a special pressure device to make the composite material denser. Put the pressurized mold back in a vacuum ove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com