Mechanical sealing device

A mechanical seal device and seal fit technology, which is applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve problems such as seal failure and large rubber deformation, and achieve good sealing performance, long service life, and not easy to fail.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

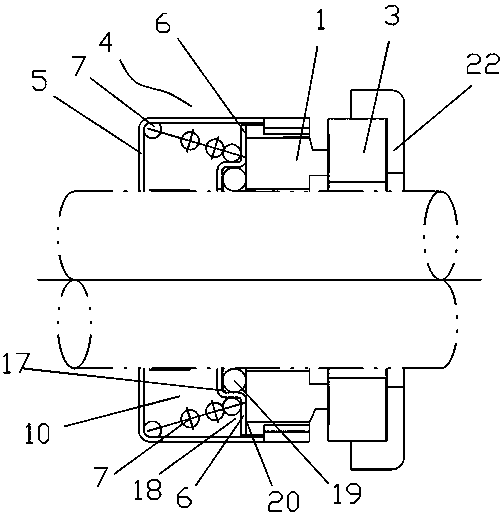

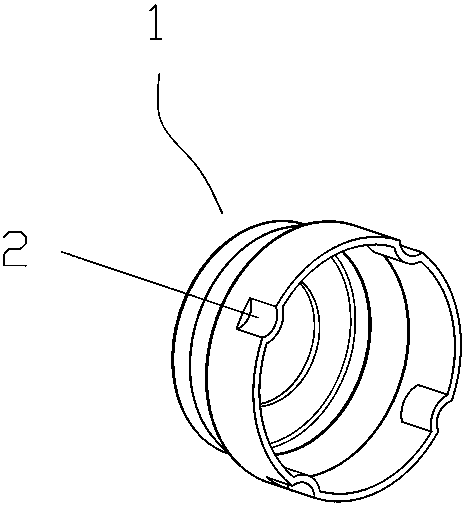

[0041] exist figure 1 , figure 2 , image 3 In the illustrated embodiment, a mechanical seal arrangement includes:

[0042] The moving ring 1 is a moving seal with sealing fit; a plurality of occlusal grooves 2 are evenly distributed on the ring surface of the moving ring 1;

[0043] The static ring 3 is a static seal that cooperates with the dynamic ring 1 to achieve sealing;

[0044]The elastic pushing component 4 is arranged on the outside of the moving ring 1 to drive the moving ring 1 to rotate and apply an axial thrust to the moving ring 1;

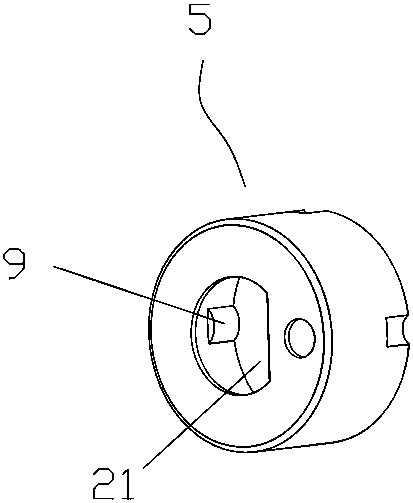

[0045] The elastic pushing assembly 4 includes a transmission seat 5, a push ring 6 and an elastic member 7. The push ring 6 is arranged inside the transmission seat 5 and connected with the end face of the moving ring 1, and the elastic member 7 is pressed between the transmission seat 5 and the push ring. between 6; the ring edge of the push ring 6 is evenly distributed with a plurality of occlusal arc grooves 8; the transmis...

Embodiment 2

[0053] exist Figure 6 , Figure 7 In the illustrated embodiment, a mechanical seal arrangement includes:

[0054] The moving ring 1 is a moving seal with sealing fit; a plurality of occlusal grooves 2 are evenly distributed on the annular surface of the moving ring 1;

[0055] The static ring 3 is a static seal that cooperates with the dynamic ring 1 to achieve sealing;

[0056] The elastic pushing component 4 is arranged on the outside of the moving ring 1 to drive the moving ring 1 to rotate and apply an axial thrust to the moving ring 1;

[0057] The elastic pushing assembly 4 includes a transmission seat 5, a push ring 6 and an elastic member 7. The push ring 6 is arranged inside the transmission seat 5 and connected with the end face of the moving ring 1, and the elastic member 7 is pressed between the transmission seat 5 and the push ring. between 6; the ring edge of the push ring 6 is evenly distributed with a plurality of occlusal arc grooves 8; the transmission se...

Embodiment 3

[0065] exist Figure 9 , Figure 10 , Figure 11 , Figure 14 In the illustrated embodiment, a mechanical seal arrangement includes:

[0066] The moving ring 1 is a moving seal with sealing fit; a plurality of occlusal grooves 2 are evenly distributed on the annular surface of the moving ring 1;

[0067] The static ring 3 is a static seal that cooperates with the dynamic ring 1 to achieve sealing;

[0068] The elastic pushing component 4 is arranged on the outside of the moving ring 1 to drive the moving ring 1 to rotate and apply an axial thrust to the moving ring 1;

[0069] The elastic pushing assembly 4 includes a transmission seat 5, a push ring 6 and an elastic member 7. The push ring 6 is arranged inside the transmission seat 5 and connected with the end face of the moving ring 1, and the elastic member 7 is pressed between the transmission seat 5 and the push ring. between 6; the ring edge of the push ring 6 is evenly distributed with a plurality of occlusal arc g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com