Abrasion-resisting and corrosion-resisting composite impeller

A composite material, corrosion-resistant technology, used in liquid fuel engines, components of pumping devices for elastic fluids, non-variable-capacity pumps, etc., can solve the problem that metal impellers cannot adapt to abrasive and corrosive conditions. , to achieve the effect of overcoming high abrasion, convenient installation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

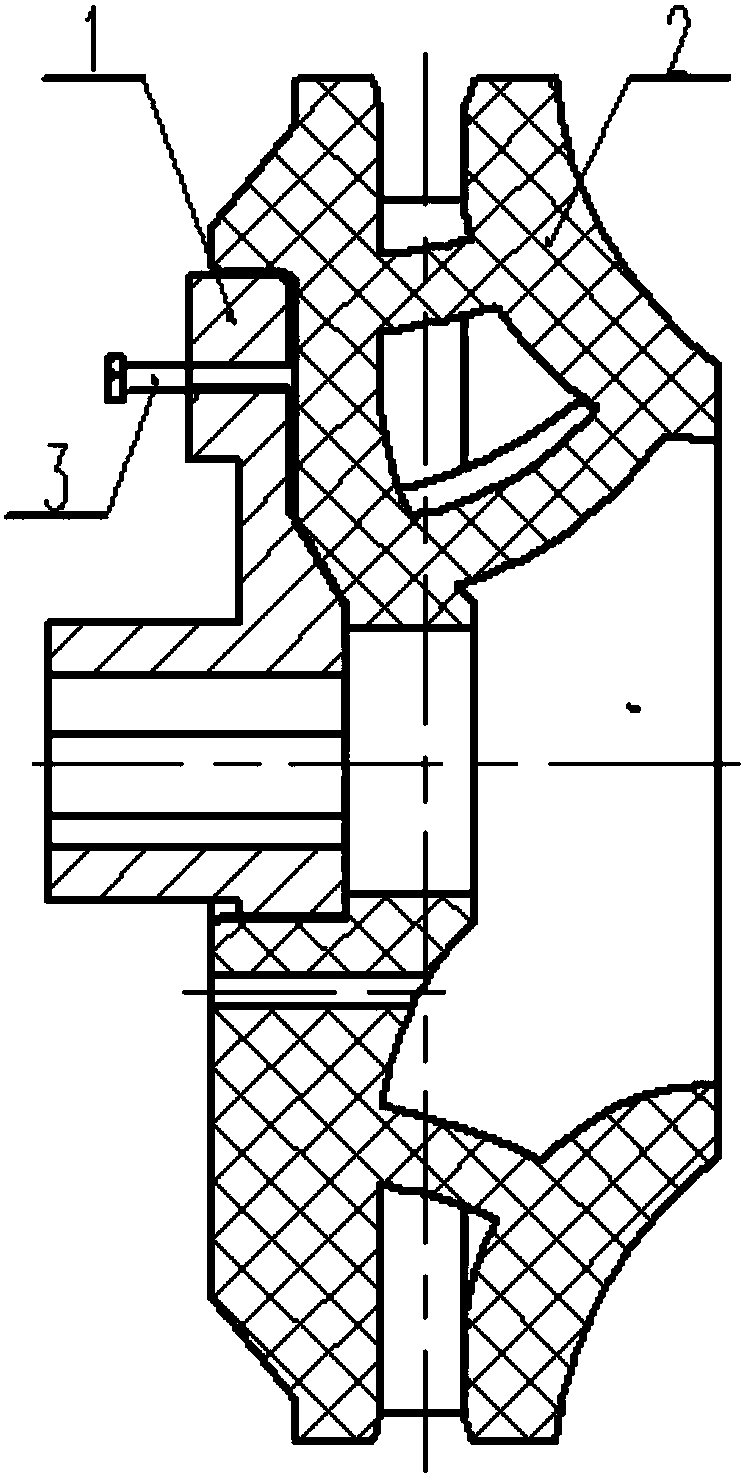

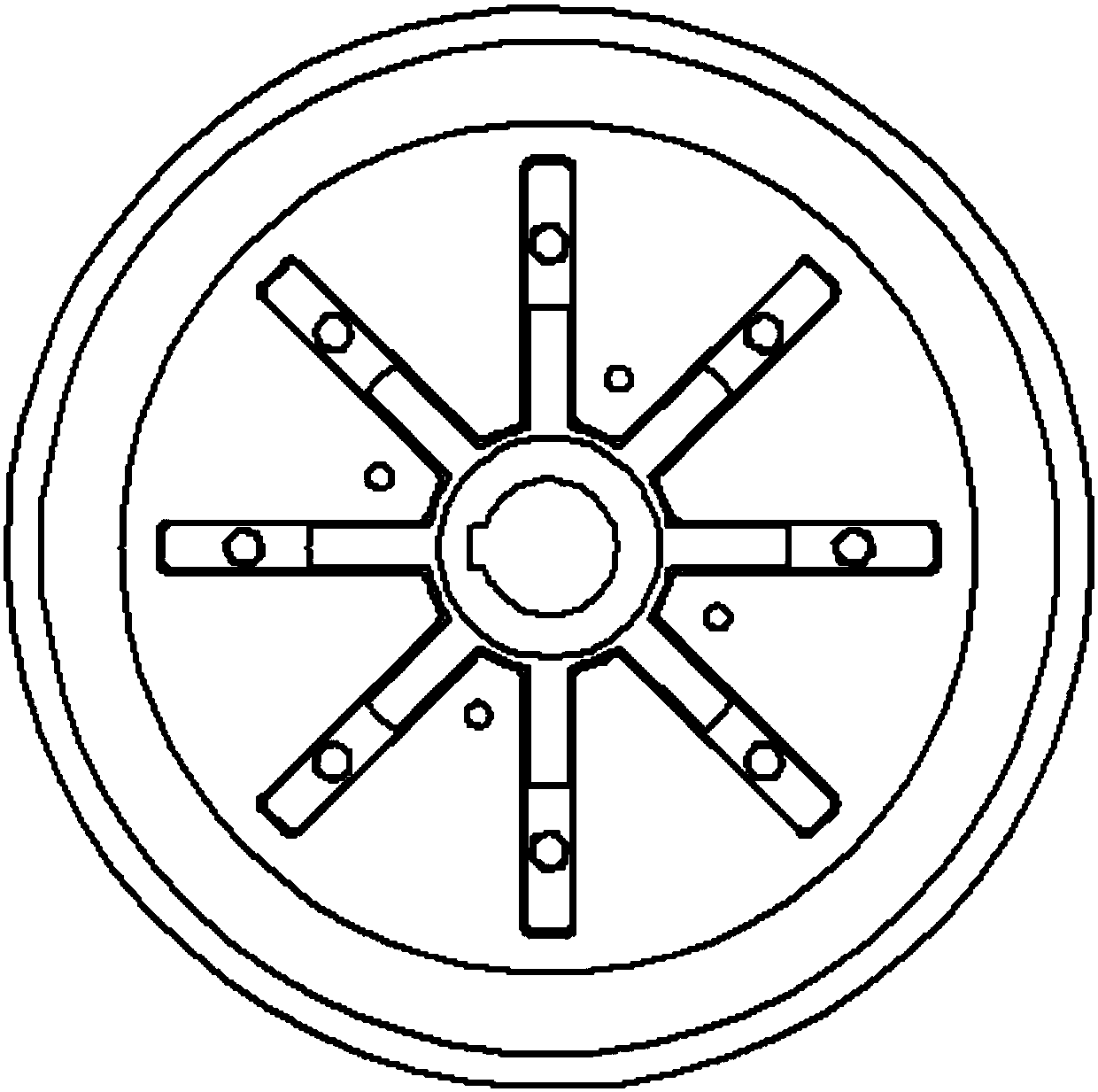

[0018] A wear-resistant and corrosion-resistant composite material impeller of the present invention, such as figure 1 , 2 As shown, including metal hub 1, ceramic blade 2;

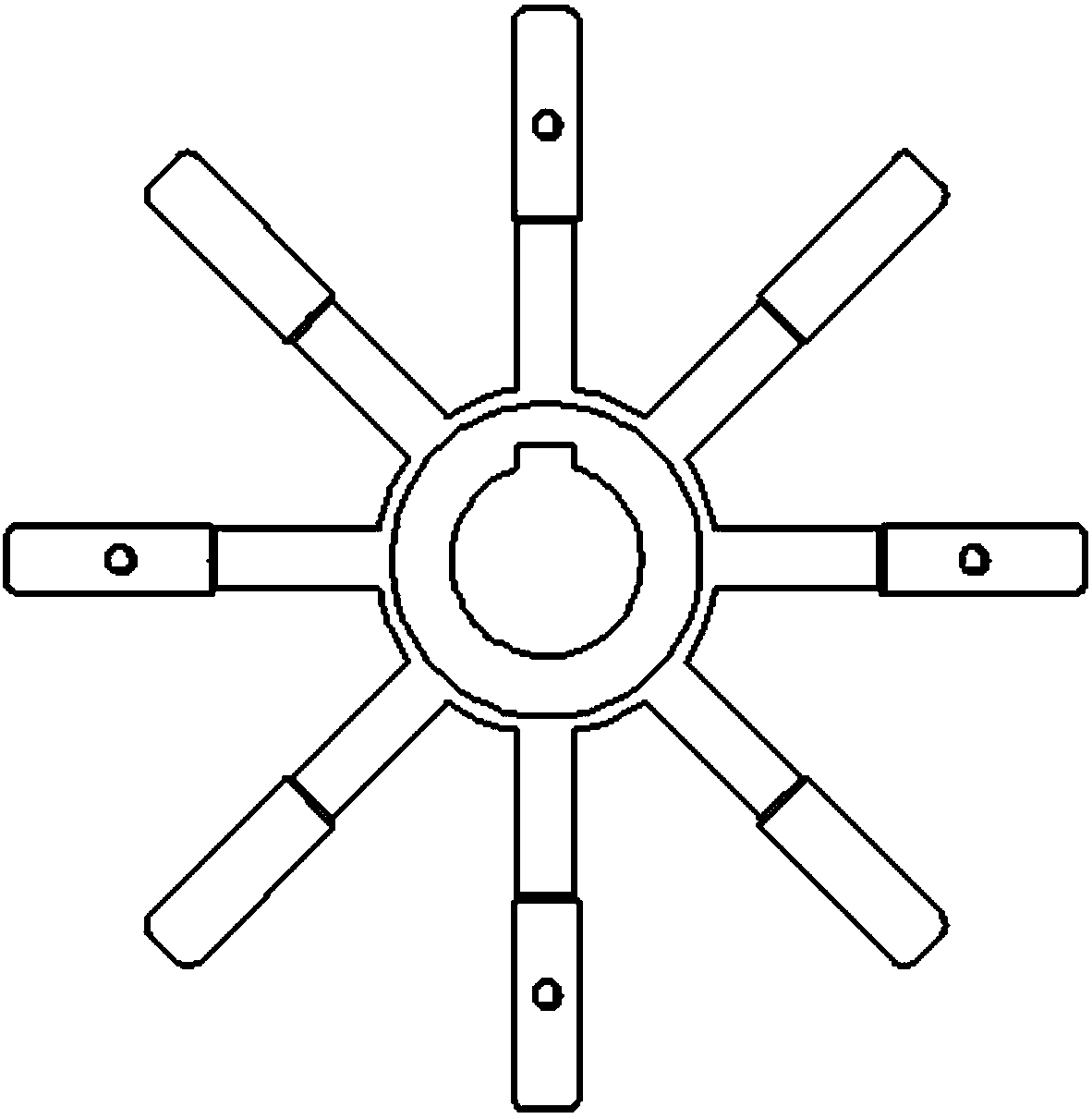

[0019] Such as image 3 As shown, the center of the metal hub 1 is a connecting ring, the inner diameter of the connecting ring matches the outer diameter of the pump shaft, and a group of circumferentially distributed connecting rods extend radially outward from the outer wall of the connecting ring, and the outer end of each connecting rod is axially There is an adjustment screw hole, and the front end surface of each connecting rod and the connecting ring form a tapered transition;

[0020] The ceramic blade 2 is an impeller blade structure made of ceramic materials. The inner diameter of the center hole of the ceramic blade 2 is larger than the outer diameter of the pump shaft, and a hub positioning groove matching the shape of the front end of the metal hub 1 is left in the center of the rear end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com