Quartz feeding barrel with repeated feeding functions for single crystal furnace

A technology of feeding barrel and repeated feeding, applied in the direction of single crystal growth, single crystal growth, polycrystalline material growth, etc., can solve the problems of high cost of feeding device, low production efficiency, container pollution, etc. The effect of improving production efficiency and no container pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

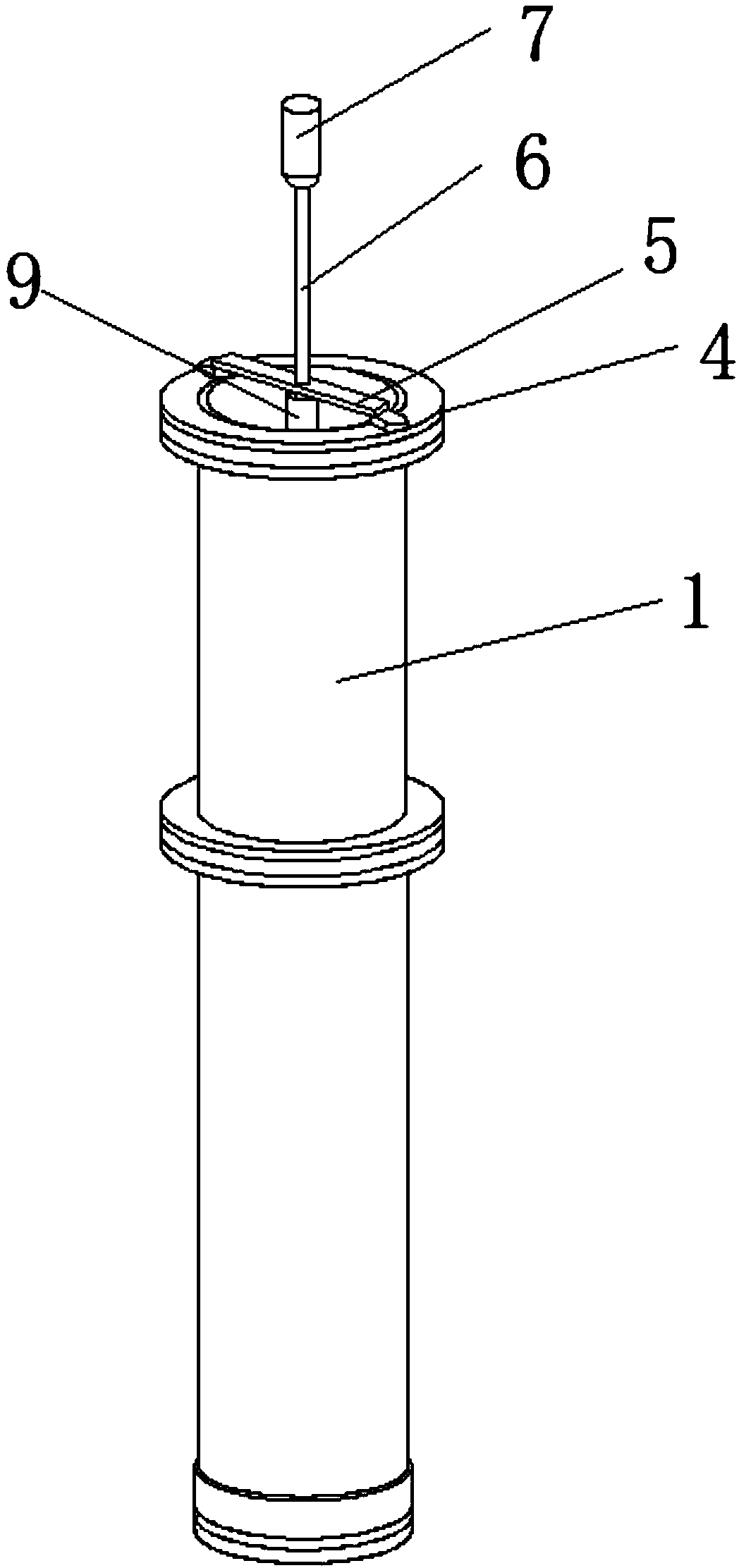

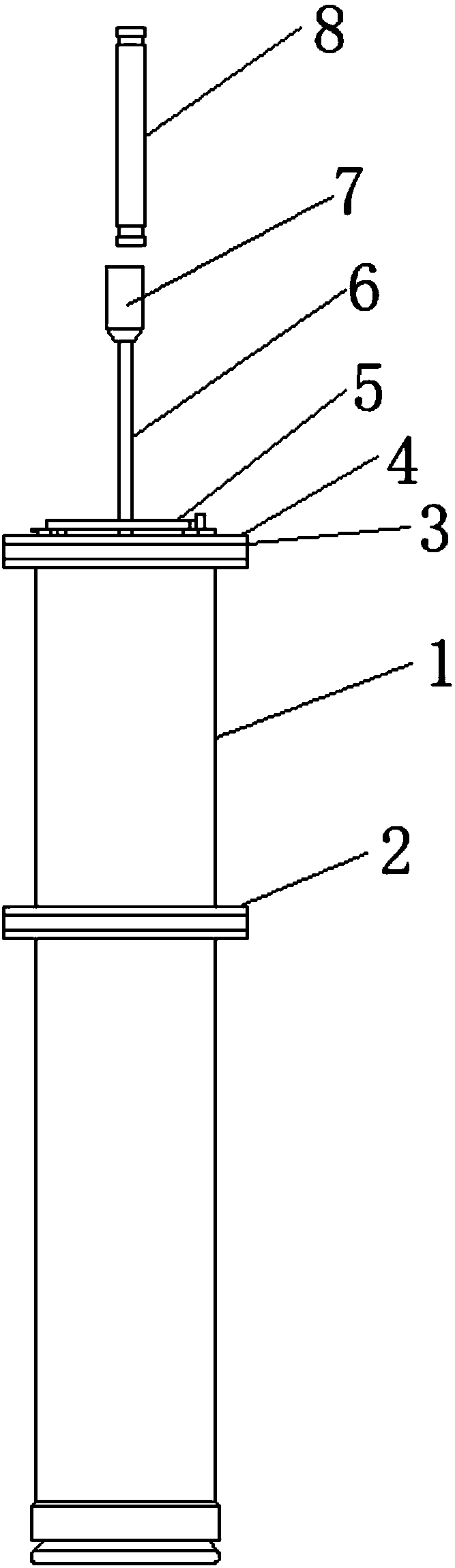

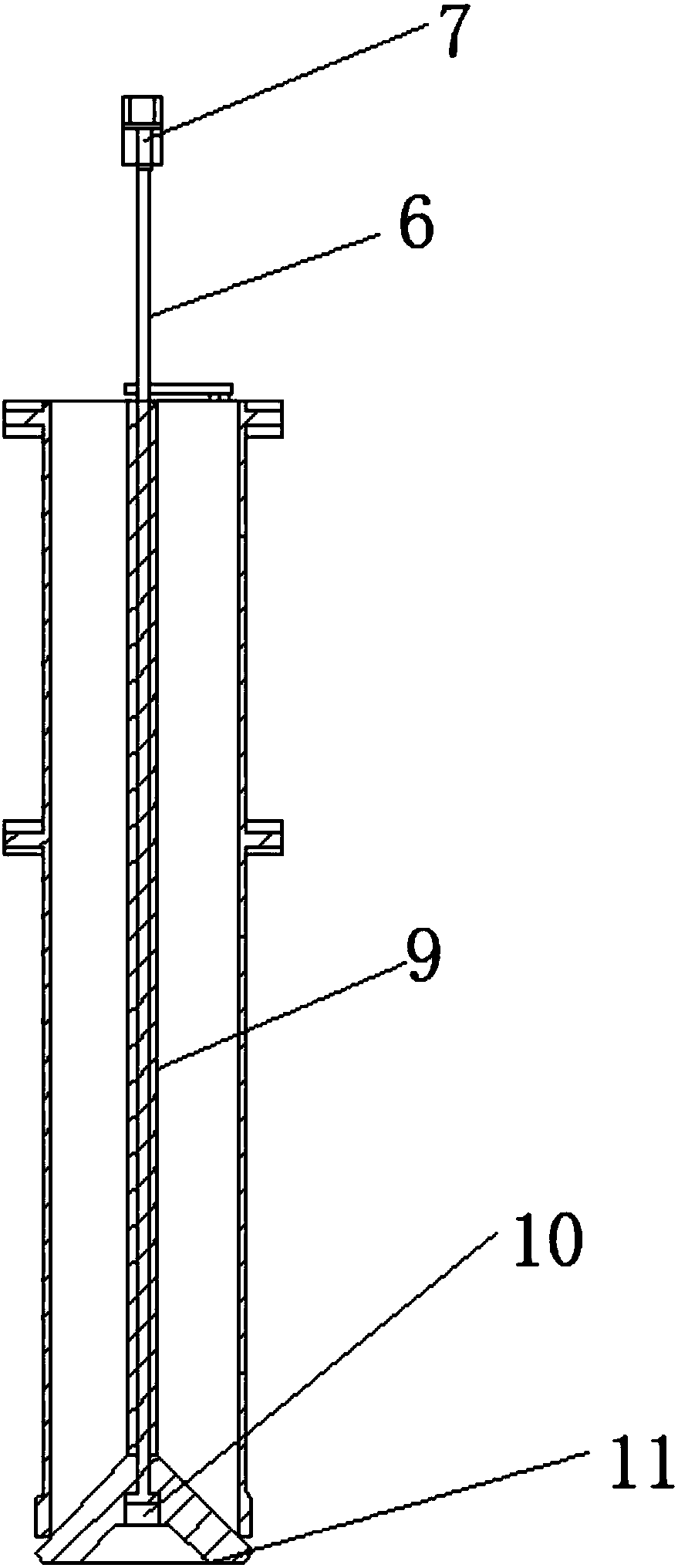

[0018] Such as Figure 1-3 As shown, a quartz feeding cylinder for repeated feeding of a single crystal furnace includes a quartz feeding cylinder 1, a No. 1 PTFE gasket 2 is provided on the surface of the quartz feeding cylinder 1, and a stainless steel reinforcement is provided at the upper end of the quartz charging cylinder 1 Ring 4, No. 2 PTFE gasket 3 is provided between the stainless steel reinforcement ring 4, a stainless steel positioning plate 5 is provided at the upper end of the stainless steel reinforcement ring 4, and a molybdenum pull rod 6 is provided at the middle end of the stainless steel positioning plate 5, so The upper end of the molybdenum pull rod 6 is provided with a stainless steel chuck 7, the interior of the stainless s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com