Titanium dioxide enveloping system and method

A titanium dioxide and coating technology, applied in chemical instruments and methods, inorganic pigment processing, fibrous fillers, etc., can solve the problem of low coating processing ability, and achieve the effect of dense film layer and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

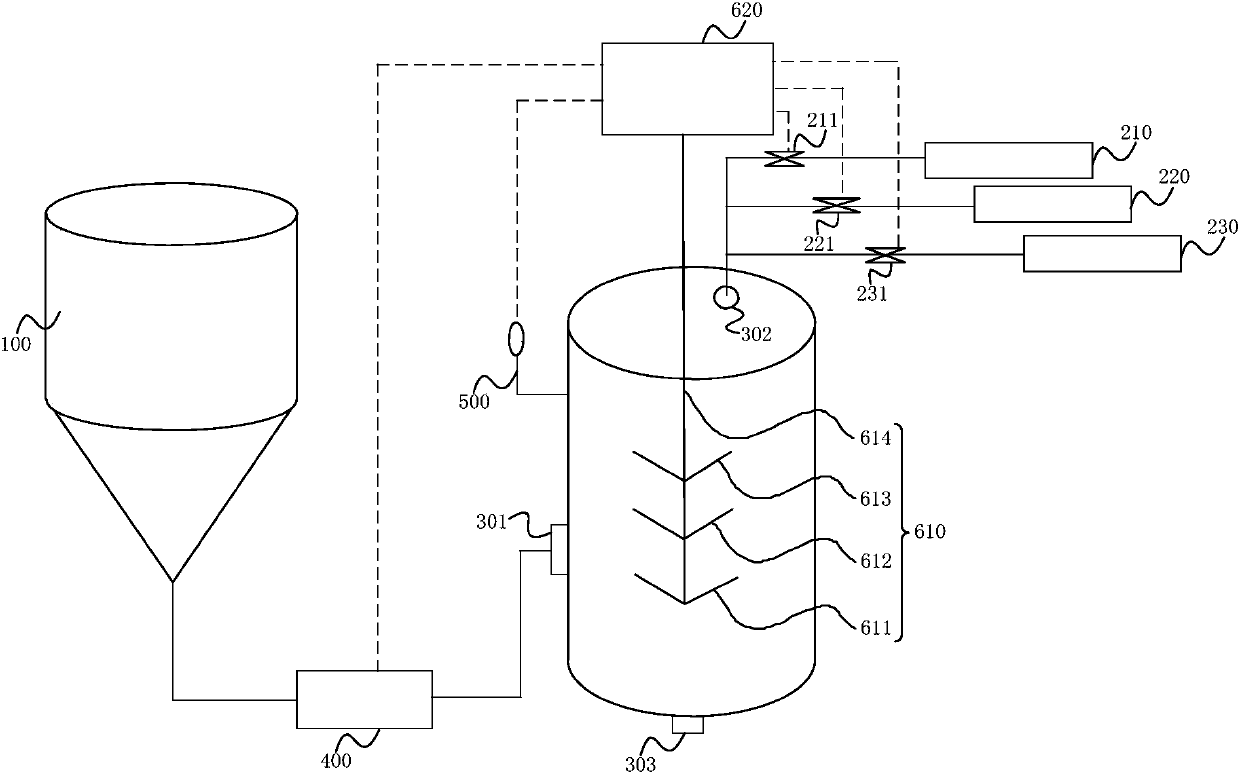

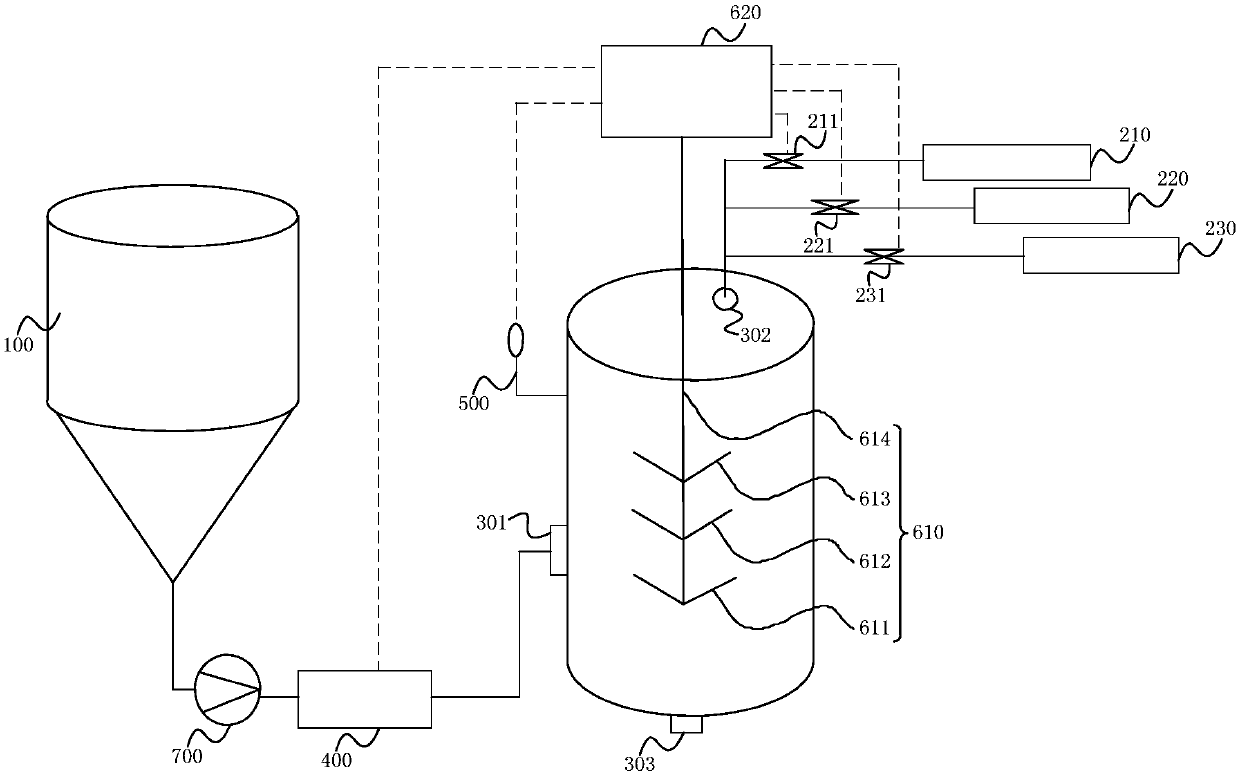

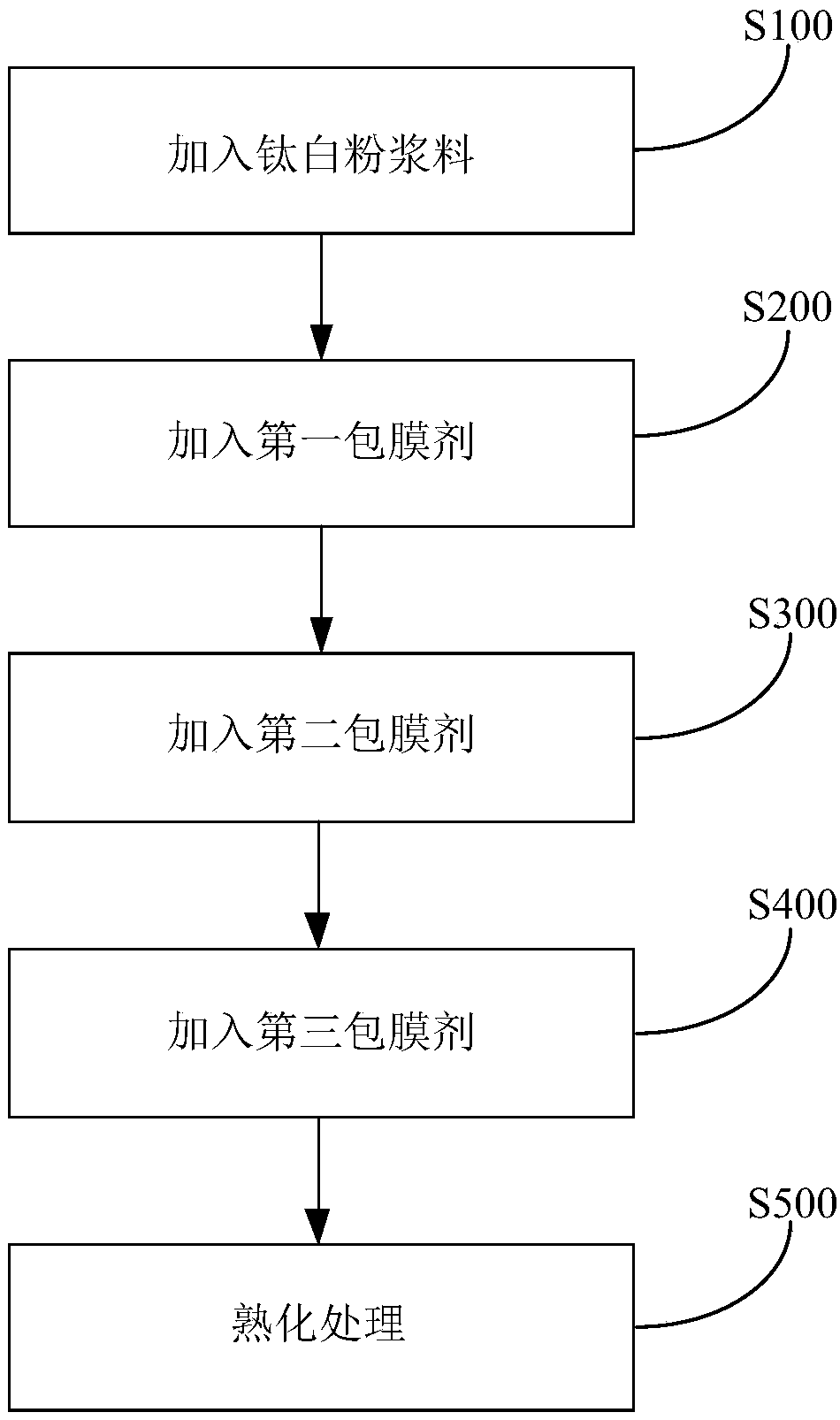

[0086] Follow the steps below to coat the titanium dioxide slurry:

[0087] (1) Add titanium dioxide slurry into the coating tank, when the liquid level in the coating tank is higher than the lower paddle, start the frequency converter, and control the multi-layer stirring paddle to stir at a speed of 40-60r / min;

[0088] When the liquid level in the coating tank is higher than the middle paddle, the frequency converter controls the multi-layer stirring paddle to stir at a speed of 60-80r / min;

[0089] When the liquid level in the coating tank is higher than the upper paddle until the feeding is completed, the frequency conversion governor controls the multi-layer stirring paddle to stir at a speed of 65-85r / min;

[0090] After the feeding is completed, the frequency converter controls the multi-layer stirring paddle to stir at a speed of 70-90r / min;

[0091] (2) Adjust the speed of the frequency converter to 65~85r / min;

[0092] (3) The first discharge valve is opened. Duri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com