Production line for preparing organic fertilizer from pig manure sewage and pig manure

An organic fertilizer and production line technology, which is applied in the production line of organic fertilizer using pig manure sewage and pig manure, can solve the problems of difficult storage, high moisture content, difficult use of pig manure, etc., and achieve easy replacement and removal, and convenient cleaning and replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

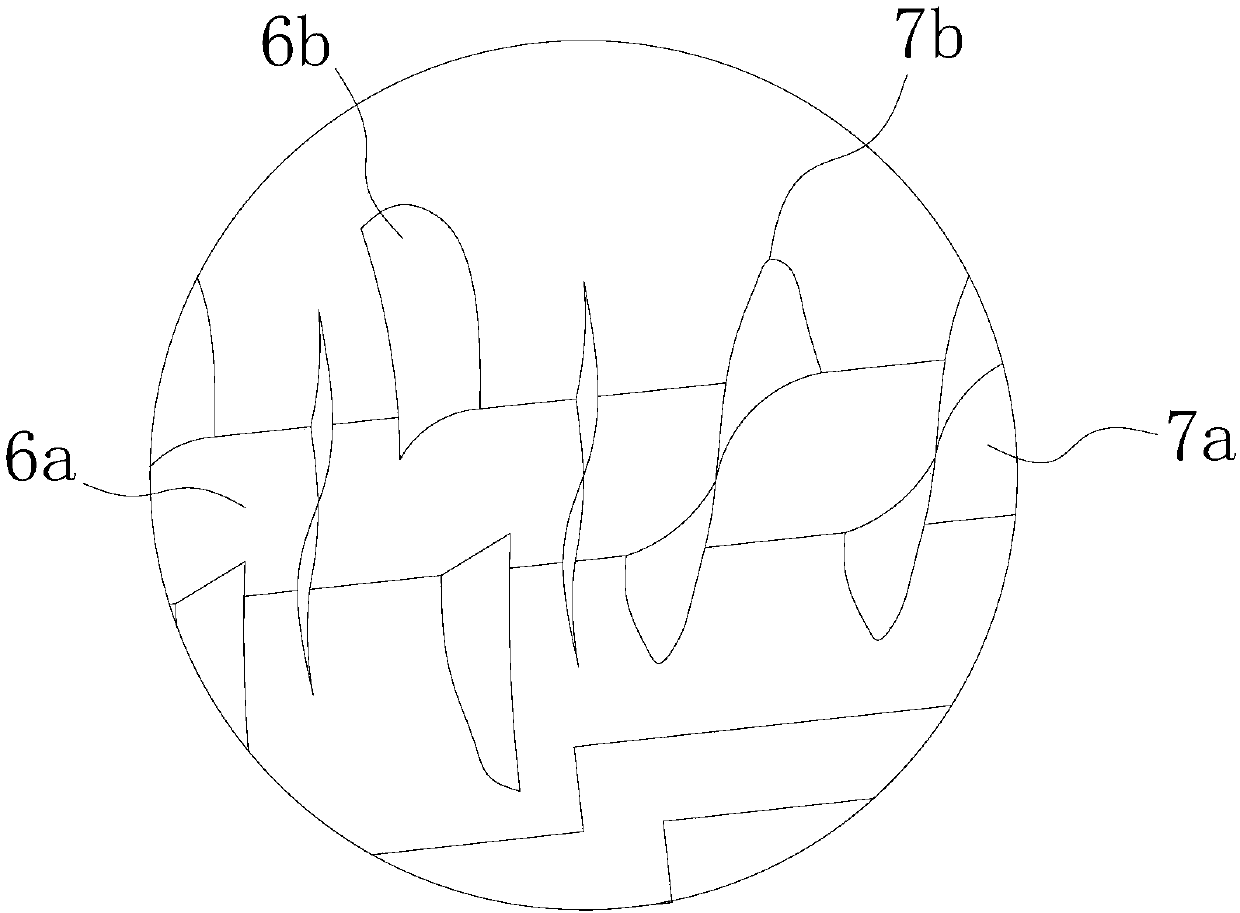

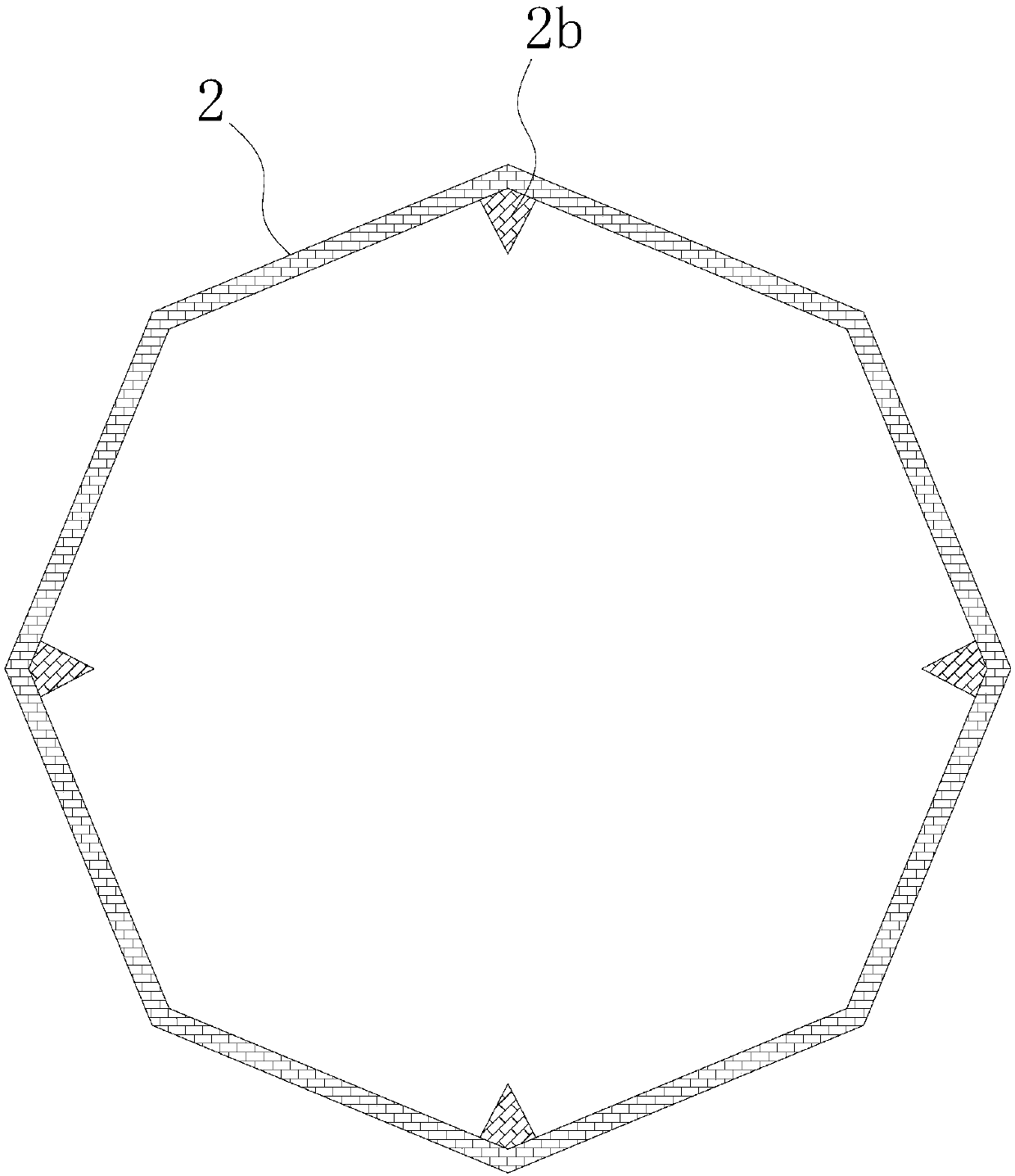

[0024] refer to Figure 1 to Figure 5 Shown, a kind of production line of the present invention utilizes pig manure sewage and pig manure to prepare organic fertilizer, comprises base 1, is provided with dung storage tank 2 on base 1, is provided with layered agitator on the dung storage tank 2, The manure storage tank 2 is connected with the sewage pipe of the external pig house. In order to make the stirring more uniform, the cross-section of the dung storage tank 2 is designed as a regular octagonal structure, and a number of stirring guide strips 2b are evenly distributed along the circumferential interval in the dung storage tank 2; Arranged in the vertical direction, the stirring guide strips 2b are diamond-shaped and located on the corners of the septic tank 2 respectively. The material is guided through the stirring guide bar to mix and stir more fully.

[0025] Below one side of the dung storage tank 2, there is a sewage filtering device 3 for filtering fecal sewage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com