Anti-puncture and anti-explosion tire and spray-dripping method and spray-dripping equipment therefor

An anti-puncture and tire technology, applied in road vehicle tires, tire parts, injection devices, etc., can solve problems such as high cost, non-adherence, tire balance misalignment, etc., to reduce the defective rate of finished products and reduce the loss of rubber. , the effect of increasing the adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0127] The main effects of the anti-puncture and anti-explosion reduction rubber spraying equipment for anti-puncture and anti-explosion reduction tires of the present invention and the single and double parallel gun body assemblies will be clearly presented in the following embodiments.

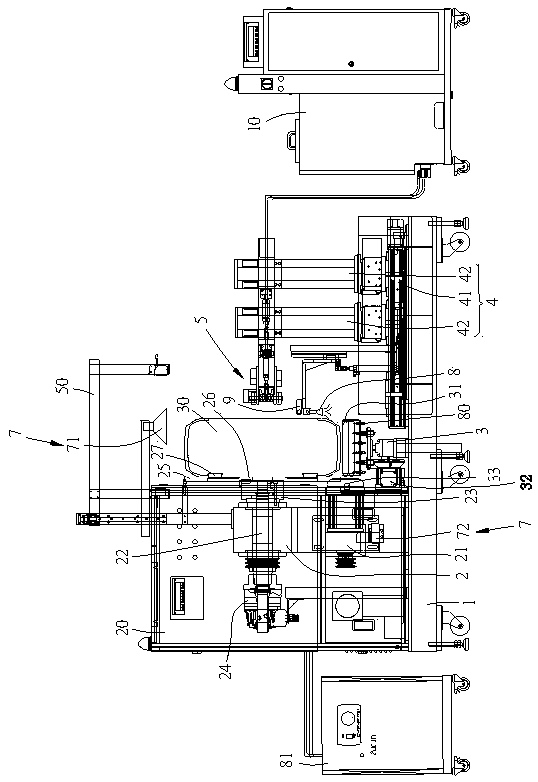

[0128] refer to figure 1 As shown, this embodiment includes:

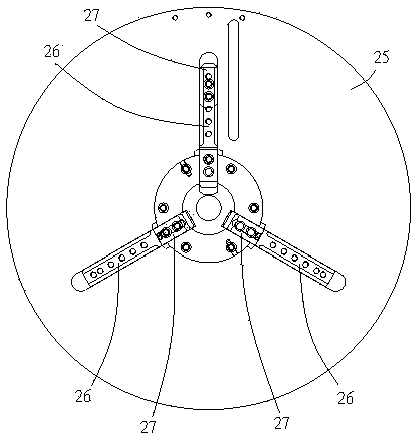

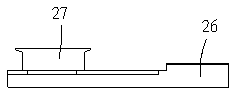

[0129] A base 1, which can be stably set on a plane by using a tripod, and is not limited by the environmental terrain and can be moved arbitrarily by using wheels to improve the economic benefits of investment and production; one side rotates the fixing device 2, the The side rotation fixing device 2 can be controlled by an oil pressure or pneumatic system; a large / small wheel replaceable bottom support device 3 is an independent pressure-sensitive support mechanism; a displacement unit 4 adopts a sliding table servo motor displacement group; a single The double parallel gun body assembly 5 is connected to the displacement unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com