Sowing mechanism for garlic

A garlic seeding machine technology, applied in potato planting machines, planting methods, applications, etc., can solve the problems of unsuitable for large-scale seeding operations, poor seeding uniformity, and high seedling density, and achieve flexible adjustment of seeding density, convenient operation, and guaranteed yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

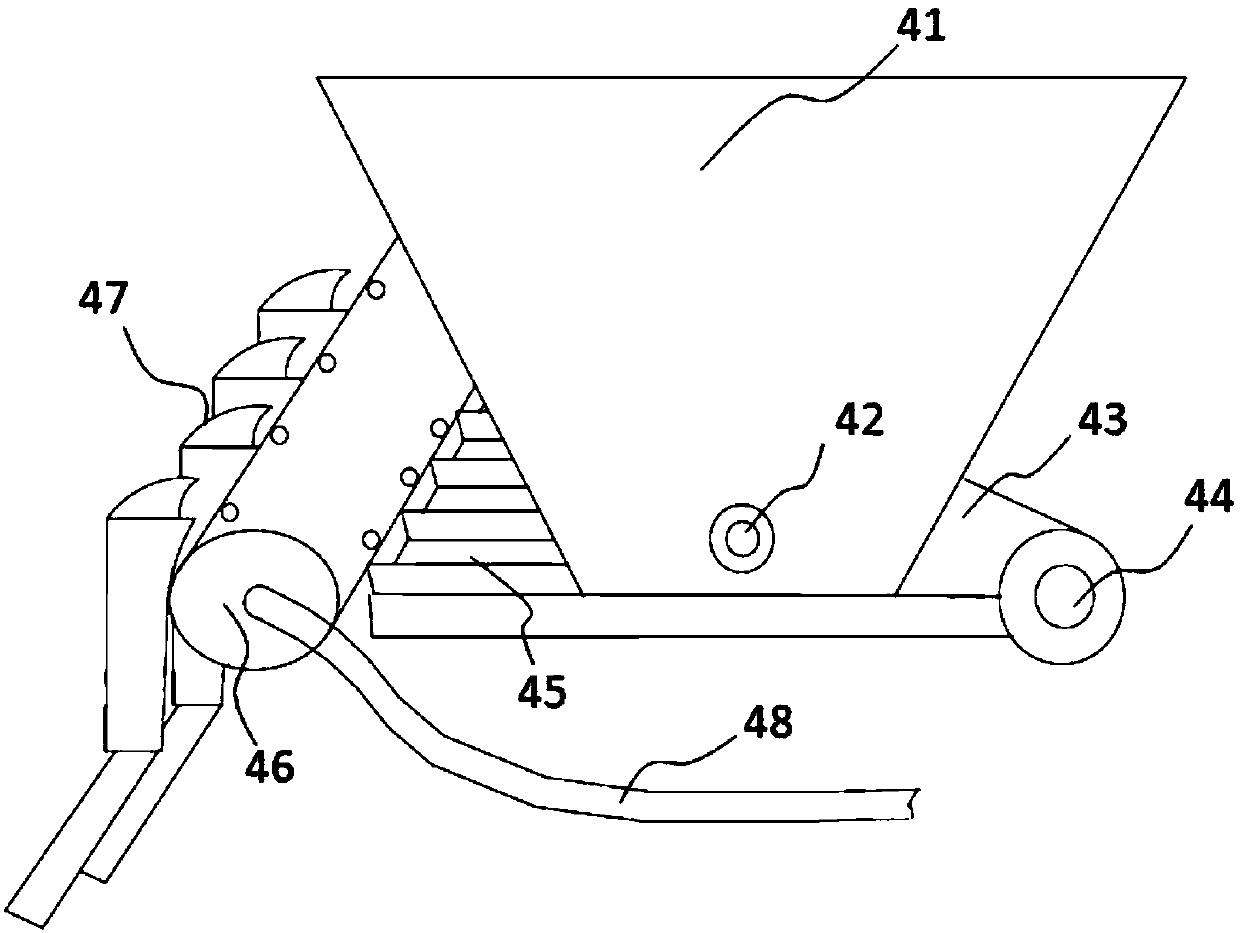

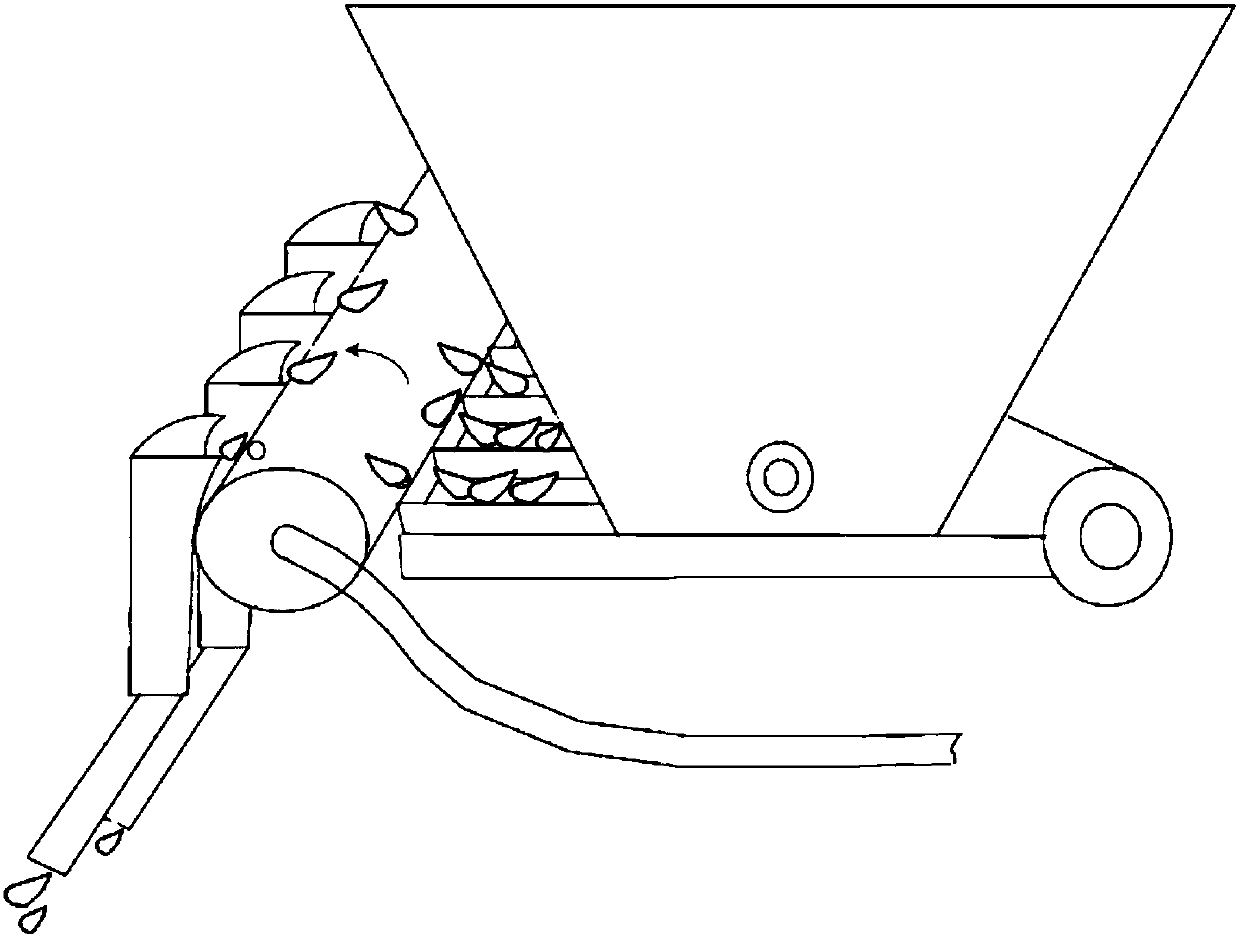

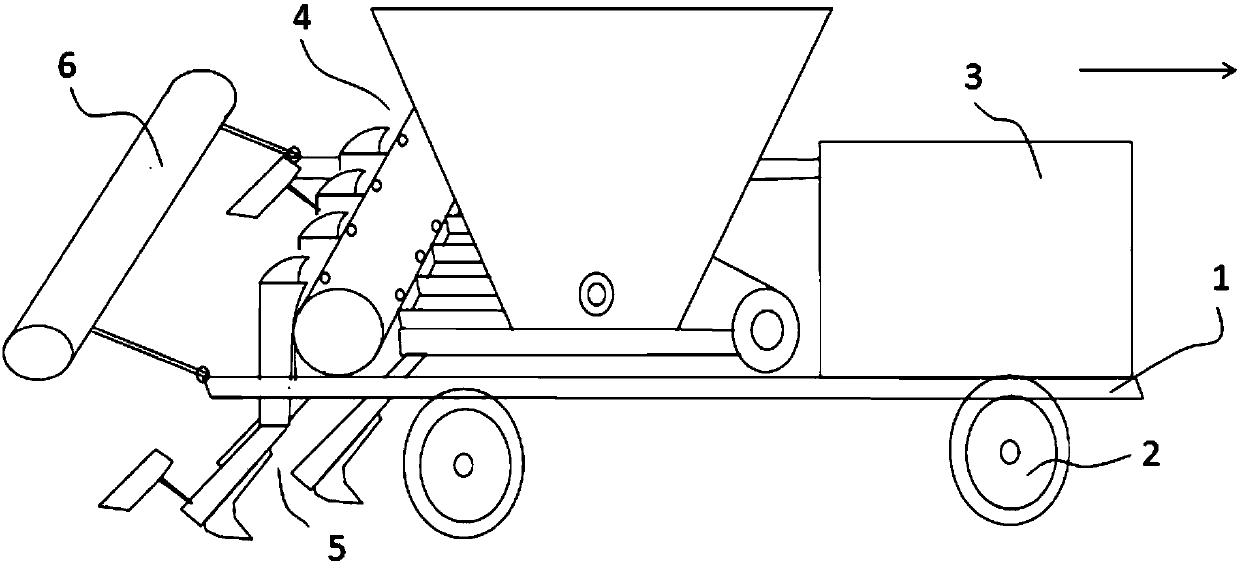

[0021] Such as figure 1 As shown, in a specific embodiment, the garlic spreading mechanism 4 provided by the present invention includes a feeding bin 41 , a feeding hopper 43 , a rotary suction cylinder 46 and a plurality of spreading pipes 47 . in:

[0022] The upper end of the feed bin 41 is open and the lower end is closed, the inner cavity of the feed bin 41 is provided with a stirring shaft 42, and the lower part of the rear side wall of the feed bin 41 is provided with a plurality of equidistantly arranged discharge mouth.

[0023] The feeding hopper 43 is arranged below the feeding bin 41, and the rear end of the feeding hopper 43 is formed with a plurality of material guide grooves 45 corresponding to the outlets one by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com