Marine reactor and once-through steam generator secondary side passive residual heat removal system

A waste heat discharge system and steam generator technology, which is applied to reactors, nuclear power generation, and greenhouse gas reduction. Road, reduce the probability of rupture, the effect of strong natural circulation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

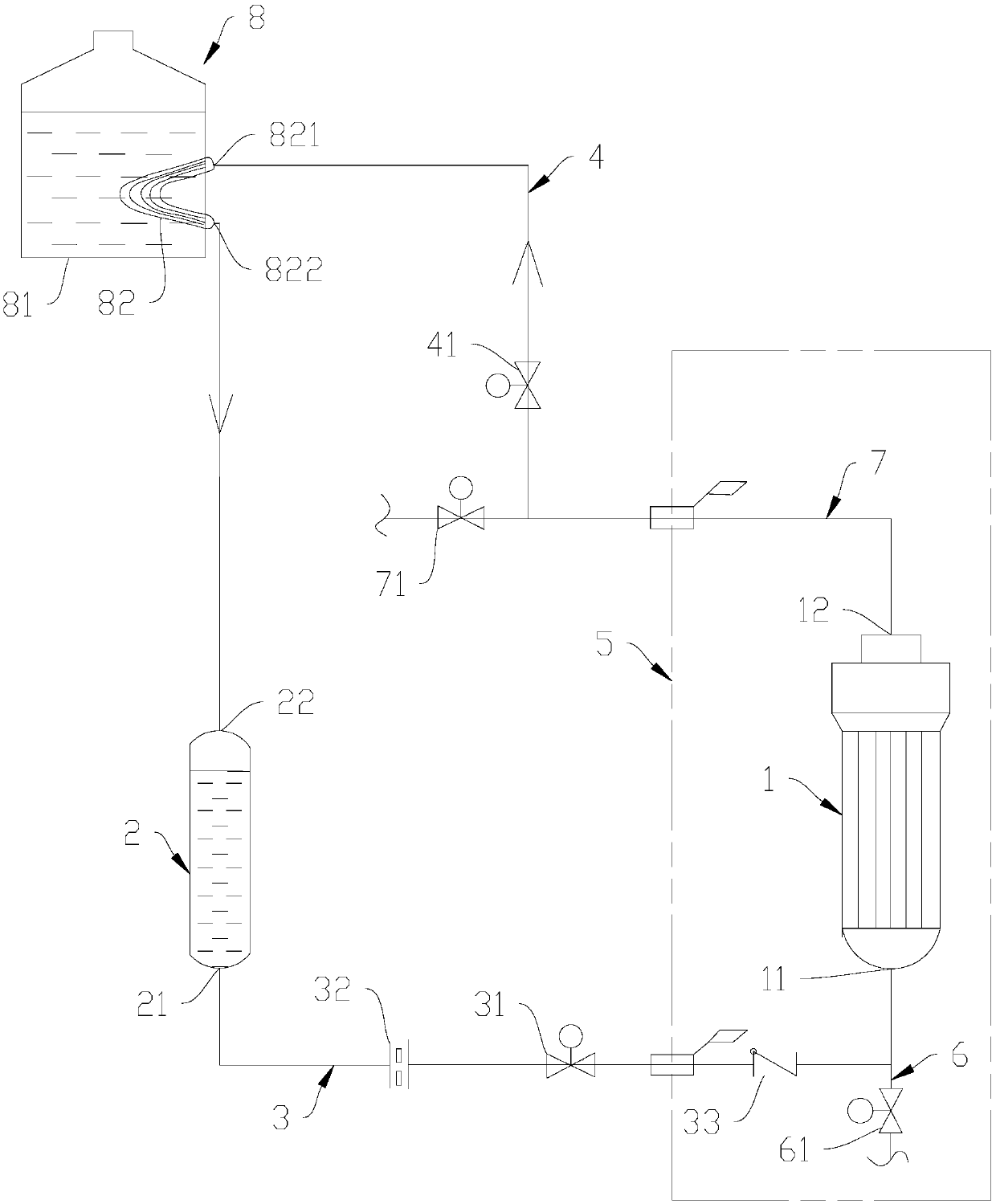

[0041] Such as figure 1 As shown, the marine reactor in a preferred embodiment of the present invention includes a once-through steam generator 1, a containment vessel 5, and a passive waste heat removal system on the secondary side of the once-through steam generator 1, and the passive waste heat removal system on the secondary side of the once-through steam generator 1 The system includes a direct-current steam generator 1, a water supply tank 2, an input pipe 3, and an output pipe 4.

[0042] The once-through steam generator 1 is arranged in the containment 5, and the first inlet 11 and the first outlet 12 are arranged on the once-through steam generator 1, and the coolant in the supplementary water tank 2 enters the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com