Novel automatic transmission gear shift switch fault detection device and detection method thereof

A technology for automatic transmissions and shift switches, applied in measuring devices, circuit breaker testing, instruments, etc., can solve problems such as waste of manpower, car accidents, and repairs outside the factory, and achieve accurate fault judgment, low cost, and high detection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

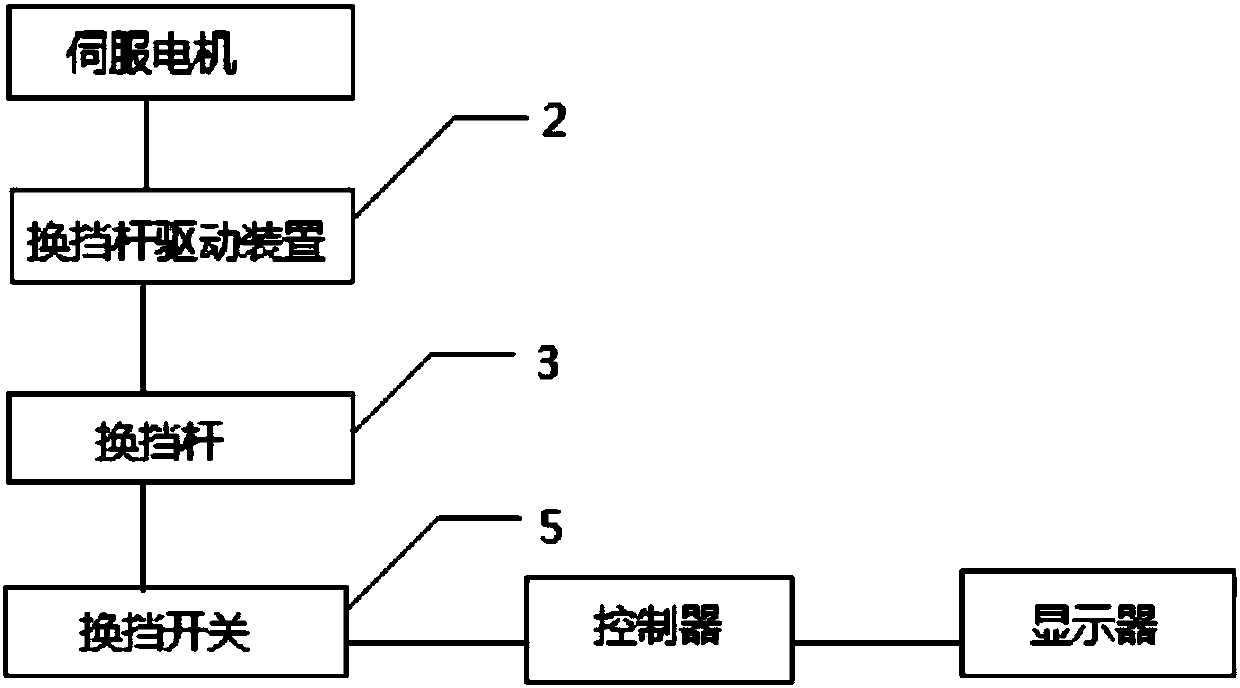

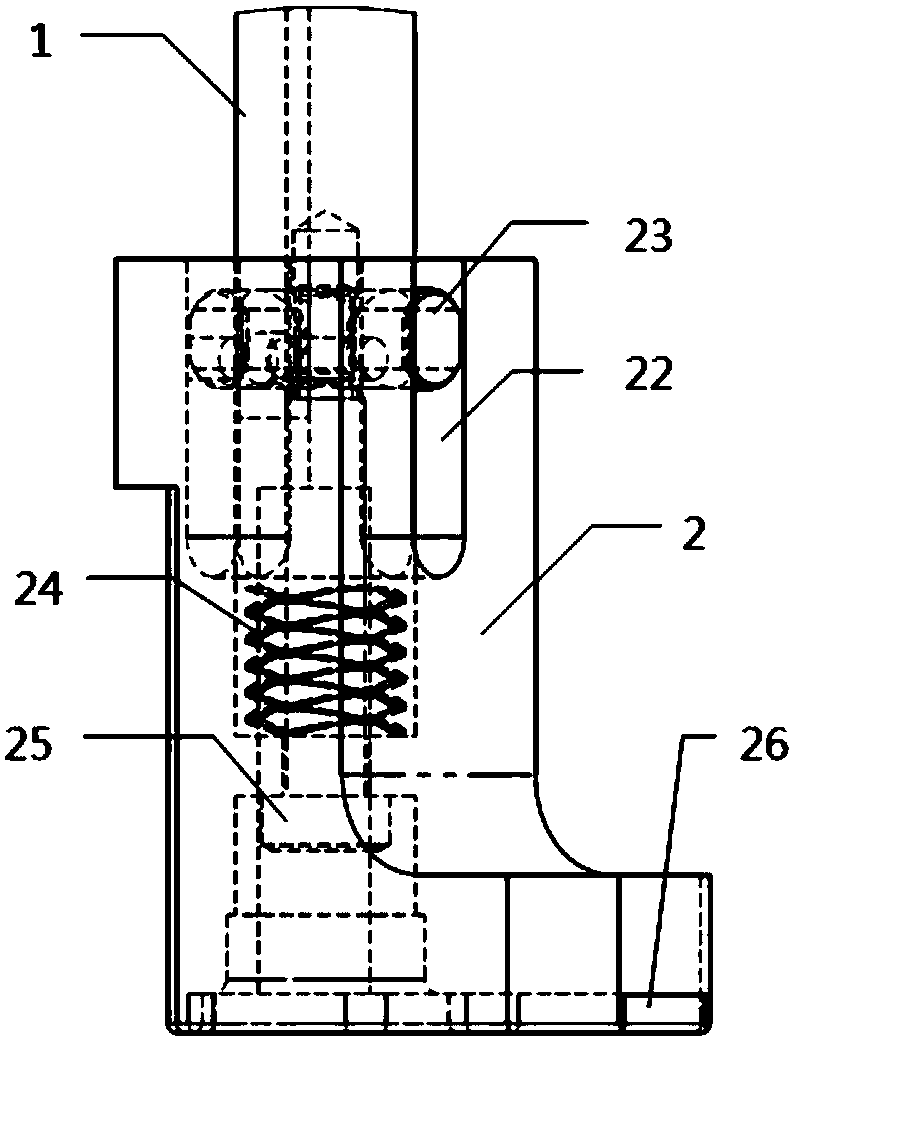

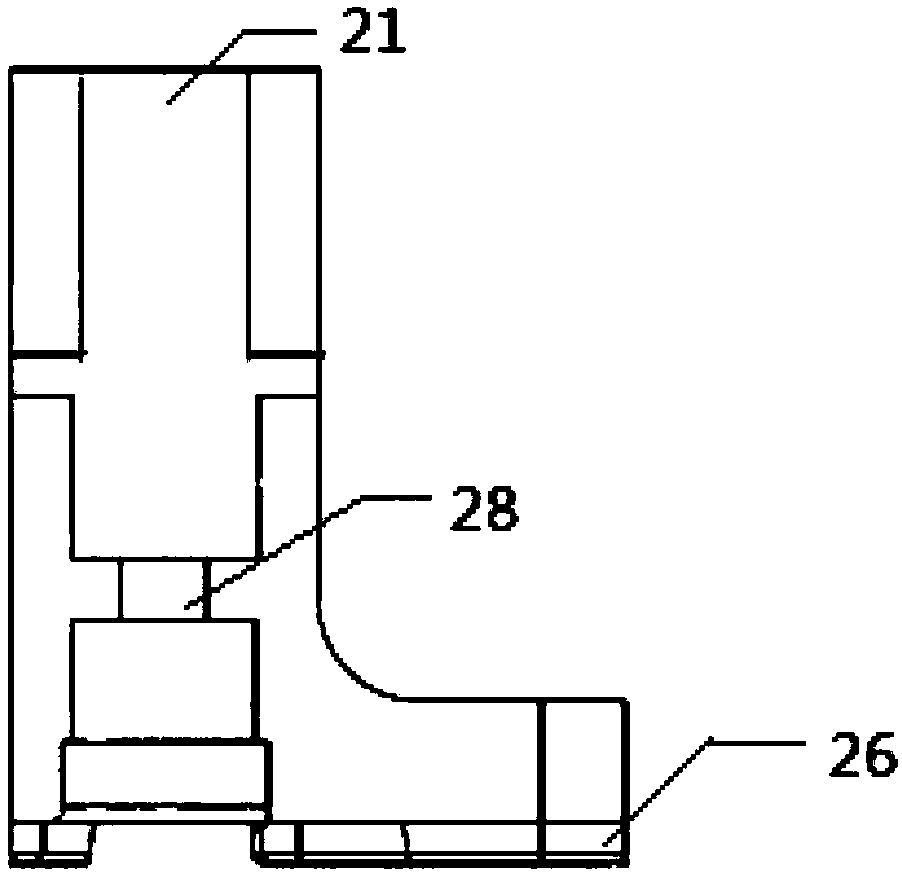

[0024] Such as figure 1 As shown, the present invention is a novel automatic transmission shift switch fault detection device, comprising a shift lever driving device 2, a shift switch 5, a shift lever 3 and a controller, and the motor used in the present invention is a servo motor, and the The controller adopts a PLC controller, the shift lever driving device 2 is connected with the motor shaft core 1 of the servo motor, and a shift lever engaging groove 26 is arranged at the bottom of the shift lever driving device 2, and the shift lever on the shift switch 5 3 is engaged with the shift lever engagement groove 26, and the shift switch 5 is electrically connected to the controller through a terminal plug 51. Such as figure 2 As shown, the top of the shift rod driving device 22 is provided with a downward shaft core installation hole 21, and the motor shaft core 1 is located in the shaft core installation hole 21, as Figure 3-5 As shown, the inner cavity of the shaft core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com