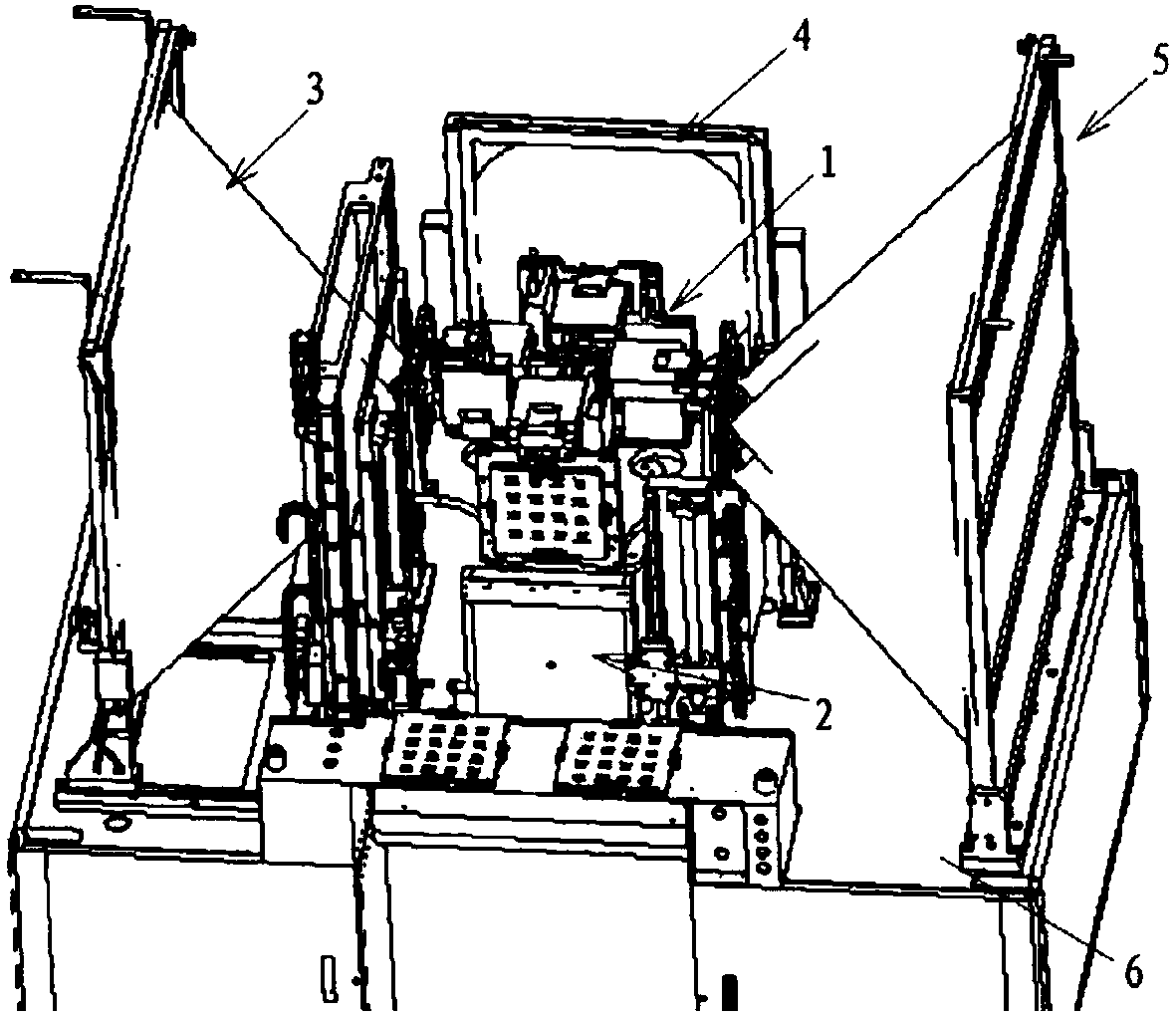

Module testing equipment and testing method

A technology of module testing and equipment, which is applied in the direction of testing optical performance, etc., and can solve the problem of low efficiency of module testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

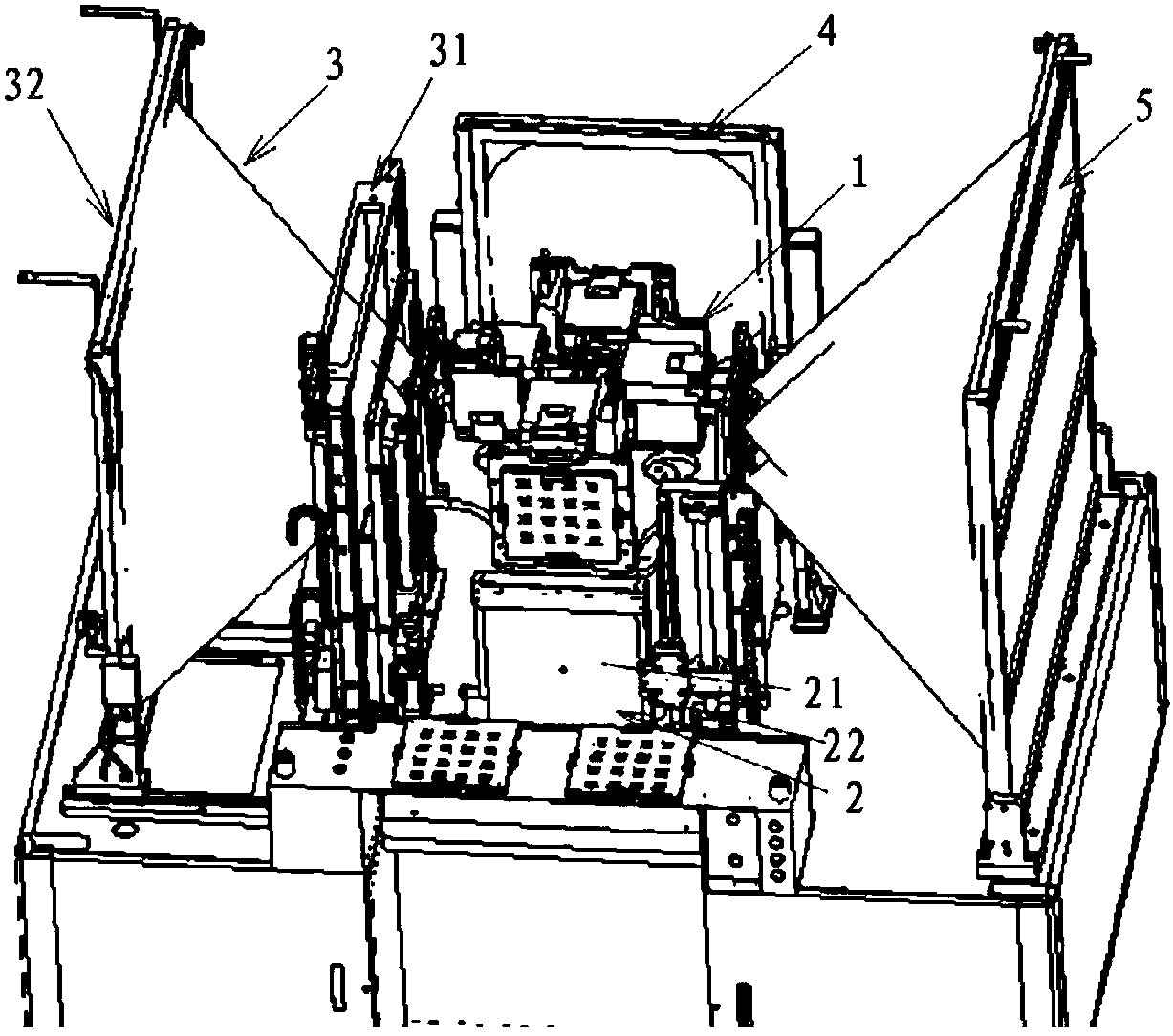

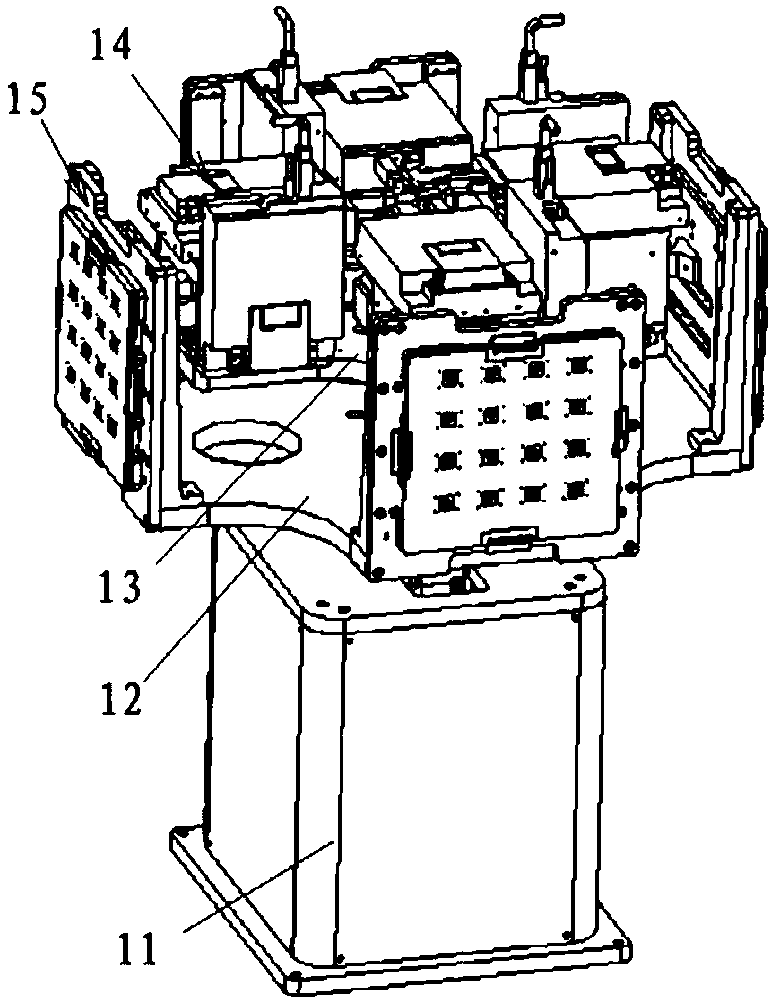

Method used

Image

Examples

Embodiment approach

[0121] combine figure 2 and Figure 5As shown, according to an embodiment of the present invention, the near-focus testing module 31 includes a near-focus light source 311 , a near-focus target plate 312 , a first near-focus driving mechanism 313 , a second near-focus driving mechanism 314 , and a near-focus support 315 . In this embodiment, the near-focus light source 311 is supported on the near-focus bracket 315 , and the near-focus light source 311 can move relative to the near-focus bracket 315 along the vertical direction. The near-focus target plate 312 is detachably installed on the near-focus light source 311 , and the near-focus target plate 312 on the near-focus light source 311 can be easily replaced according to test requirements. The first near-focus driving mechanism 313 is connected with the near-focus light source 311, and the near-focus light source 311 can move up and down in the vertical direction by driving the first near-focus driving mechanism 313, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com