Range hood oil cup oil quantity detection device

A range hood oil and detection device technology, which is applied in the fields of oil fume removal, household heating, lighting and heating equipment, etc., can solve the problem of inaccurate measurement of detection probes, achieve inaccurate measurement avoidance, high-precision measurement, and expand applications range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

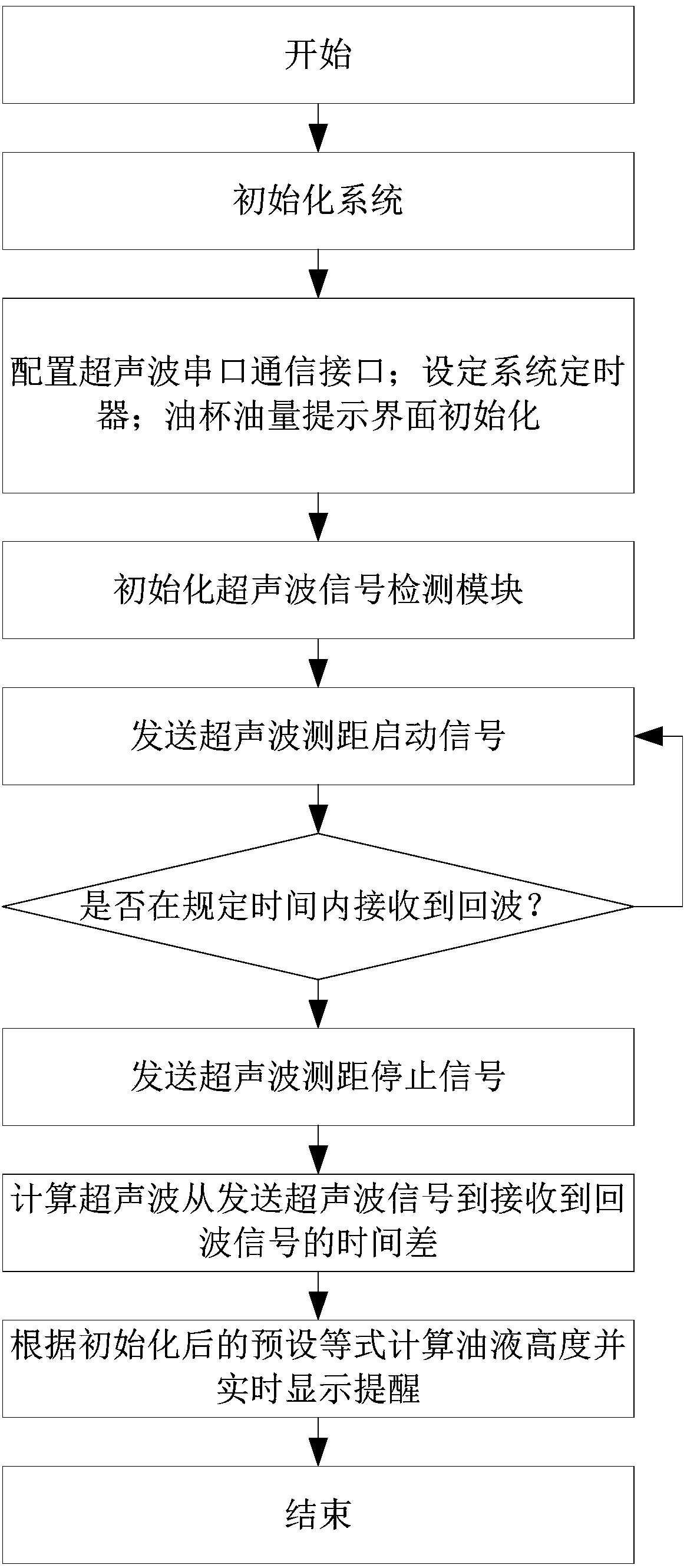

[0049] A device for detecting the amount of oil in the oil cup of a range hood, such as figure 1 As shown, the oil detection device includes: an ultrasonic probe 1, an ultrasonic signal detection module 2 and a main control unit 3 connected in sequence;

[0050]Ultrasonic probe 1 is used to transmit ultrasonic signals to the oil cup and detect ultrasonic echo signals generated on the medium layer between the oil and the air in the oil cup;

[0051] The ultrasonic signal detection module 2 is used to calculate the time difference between the moment of receiving the ultrasonic echo signal and the moment of transmitting the ultrasonic signal;

[0052] The main control unit 3 is used to calculate the oil level in the oil cup according to the time difference and the preset equation.

[0053] In the embodiment of the present invention, the solution of this embodiment is a real-time and high-precision oil detection system for the oil cup of the range hood based on ultrasonic liquid ...

Embodiment 2

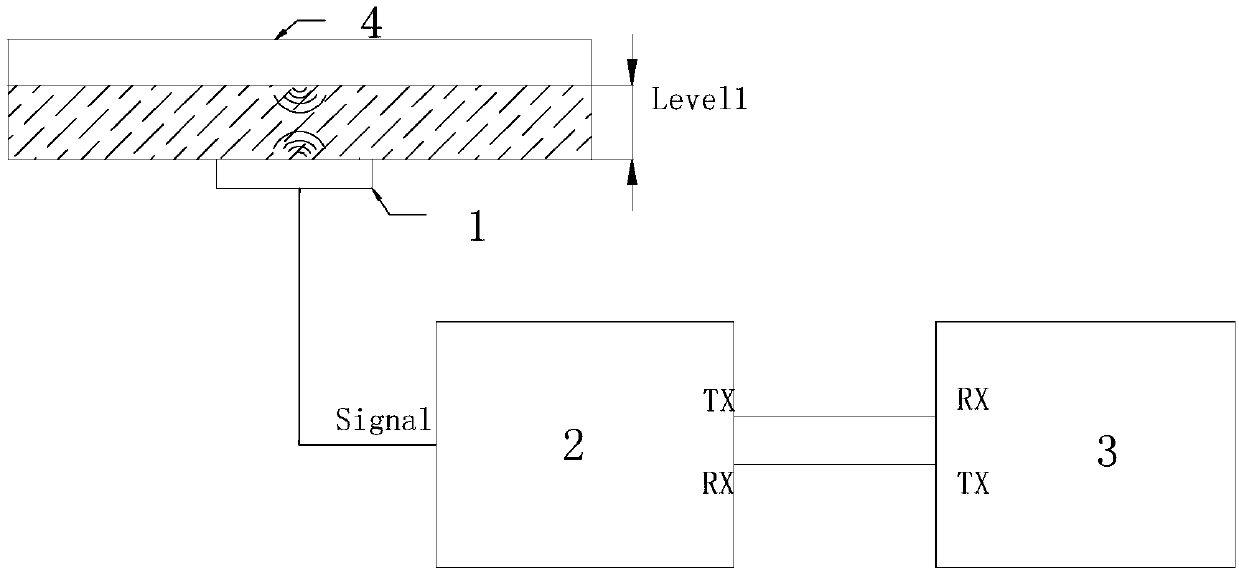

[0057] In this embodiment, on the basis of the first embodiment, the installation method of the ultrasonic probe 1 is further limited.

[0058] Optionally, the installation method of the ultrasonic probe 1 includes: being fixed at the bottom outside the oil cup 4 or at a predetermined height above the oil cup 4 .

[0059] Option 1. Ultrasonic probe under-mounted installation method

[0060] In the embodiment of the present invention, such as image 3 As shown, it is the overall schematic diagram when the ultrasonic probe 1 is installed under the installation mode, that is, when the ultrasonic probe 1 is fixed on the bottom outside the oil cup 4 . The embodiment scheme in which the ultrasonic probe 1 is fixed on the bottom of the outer side of the oil cup 4 does not require the material of the oil cup 4, no matter whether the oil cup 4 is made of metal or plastic, it will not affect the measurement of the oil volume of the oil cup 4 , and this embodiment solves the problem of...

Embodiment 3

[0075] In this embodiment, on the basis of the second embodiment, the measurement principles of the two installation methods of the ultrasonic probe 1 are further introduced.

[0076] For option 1, the installation method of the ultrasonic probe under the

[0077] In the embodiment of the present invention, such as image 3 As shown, the ultrasonic probe 1 is a piezoelectric sensor as an example for description. When the piezoelectric sensor is fixed on the bottom of the outer side of the oil cup 4, the piezoelectric sensor generates a pulse from the bottom of the oil cup 4, the pulse passes through the bottom shell of the oil cup, passes through the liquid in the oil cup until it reaches the liquid surface, and on the liquid surface (liquid to air interface) creates an echo. The echo triggers the ultrasonic probe 1 again, so that the ultrasonic probe 1 generates a signal and transmits it back to the ultrasonic signal detection module 2. The ultrasonic signal detection modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com