Electrically controlled solid propellant rocket engine adjustable in thrust and capable of being started several times

A solid propellant, rocket motor technology, applied in rocket motor devices, machines/engines, jet propulsion devices, etc., can solve the problems of difficult control of solid rocket motor thrust, inability to start multiple times, and slow thrust adjustment response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

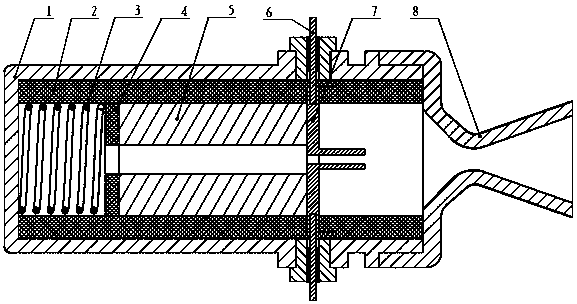

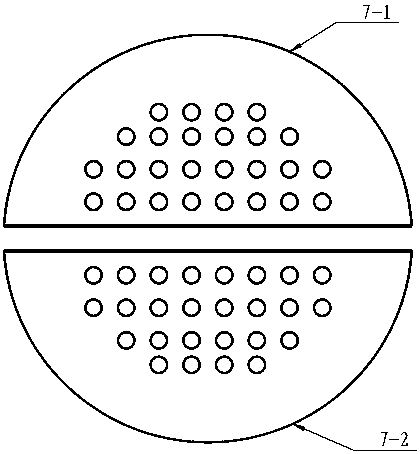

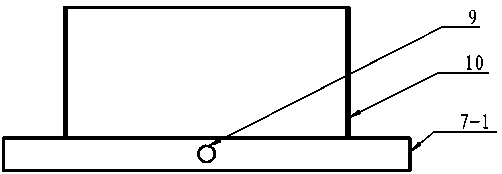

[0024] Such as figure 1 As shown, the present invention includes a combustion chamber casing 1, an insulating layer 2, a spring 3, a movable insulating plate 4, an electrically controlled solid propellant grain 5, a terminal post 6, a coplanar electrode 7 and a nozzle 8. The electronically controlled solid propellant grain 5 is installed in the combustion chamber housing 1, and the lower end of the electrically controlled solid propellant grain 5 has a movable insulating plate 4, and is used to push the movable insulating plate 4 and the electrically controlled solid propellant grain. 5 springs 3. The charge structure of the electronically controlled solid propellant grain 5 is a circular tube type, and the inner hole of the circular tube type grain can be used for gas discharge. The coplanar electrode 7 includes two identical porous electrodes, symmetrically distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com