Synchronous belt type hairbrush sweeping device

A technology of cleaning device and synchronous belt, which is used in cleaning device, transportation and packaging, conveyor objects, etc., to achieve the effect of powerful function, compact structure and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The principles and features of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

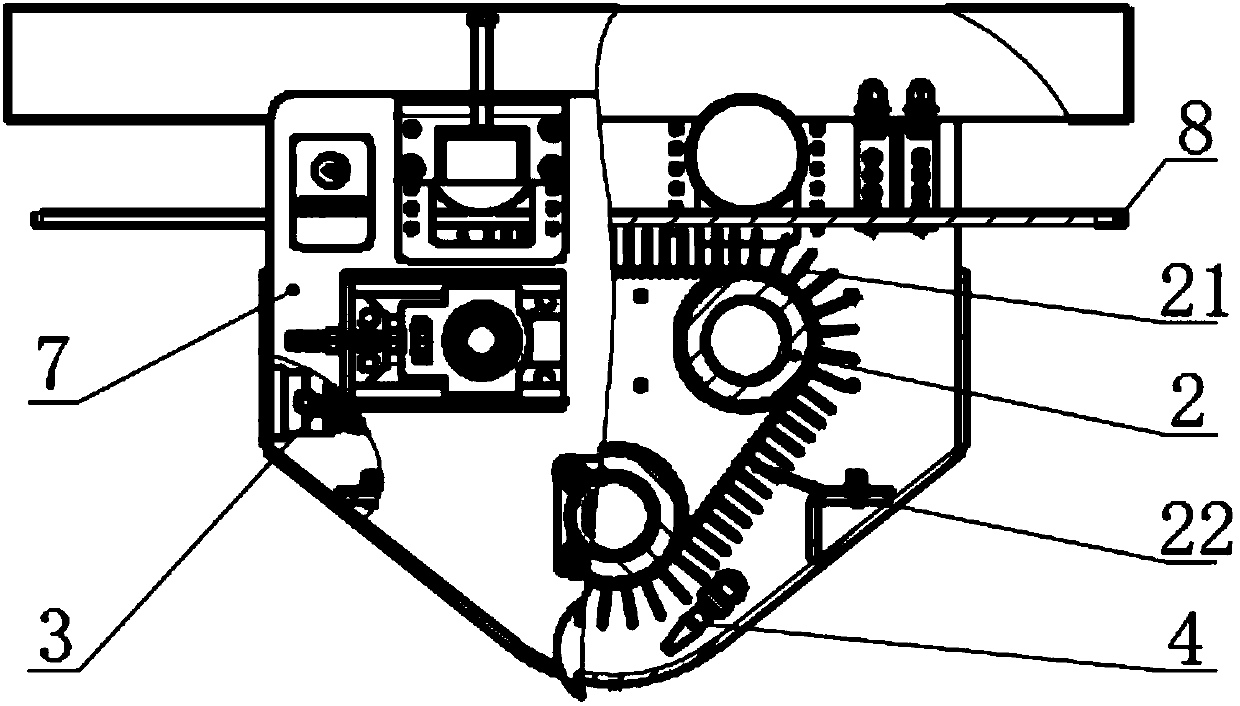

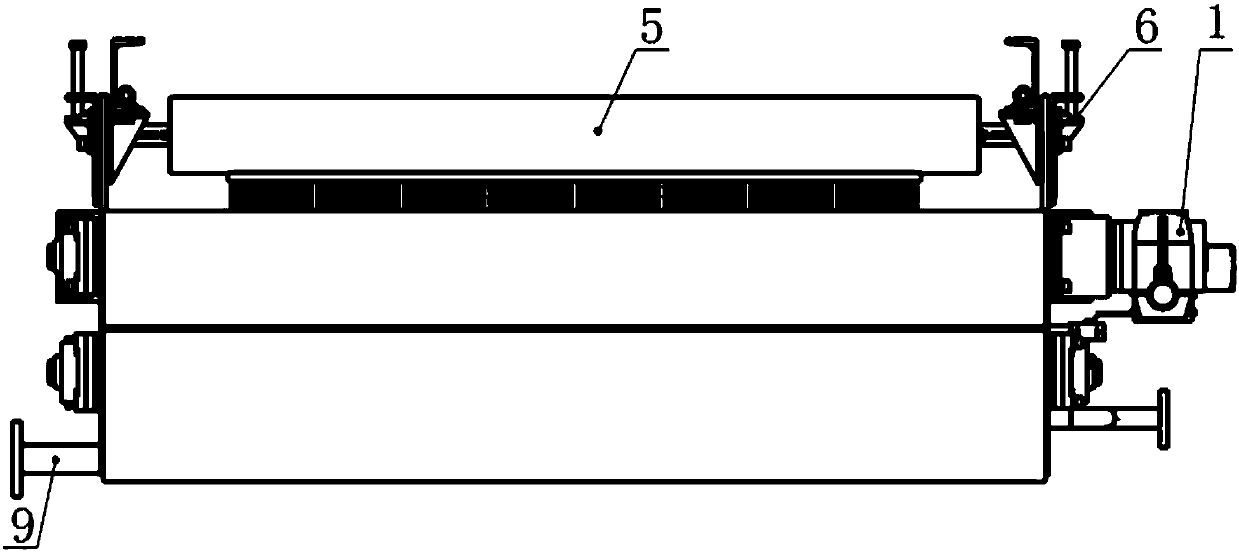

[0022] see Figure 1 ~ Figure 2 As shown, the synchronous belt type brush cleaning device of the present invention comprises a cleaning box 7, and a driving device 1, a brush timing belt cleaning device 2, a spraying device 3, a cleaning device 4, and a pressing device 5 are arranged in the cleaning box 7 And adjusting device 6, described driving device 1 is made up of motor, speed reducer and electric control system; Brush synchronous belt cleaning device 2 is made up of three groups of synchronous pulley groups, brush synchronous belt 21, comb-shaped cleaning plate 22, three One group of synchronous pulley groups is driven by a motor as the driving pulley group, and the other two groups are driven pulley groups. The synchronous pulley group consists of 8 synchronous pulleys that are installed in series on the shaft throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com