Semi-feeding self-propelled peanut combined harvester

A combine harvester and self-propelled technology, which is applied in the direction of digging harvesters, harvesters, agricultural machinery and implements, etc., can solve the problems of low peanut efficiency and high labor costs, and achieve low production costs, easy operation and smooth operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

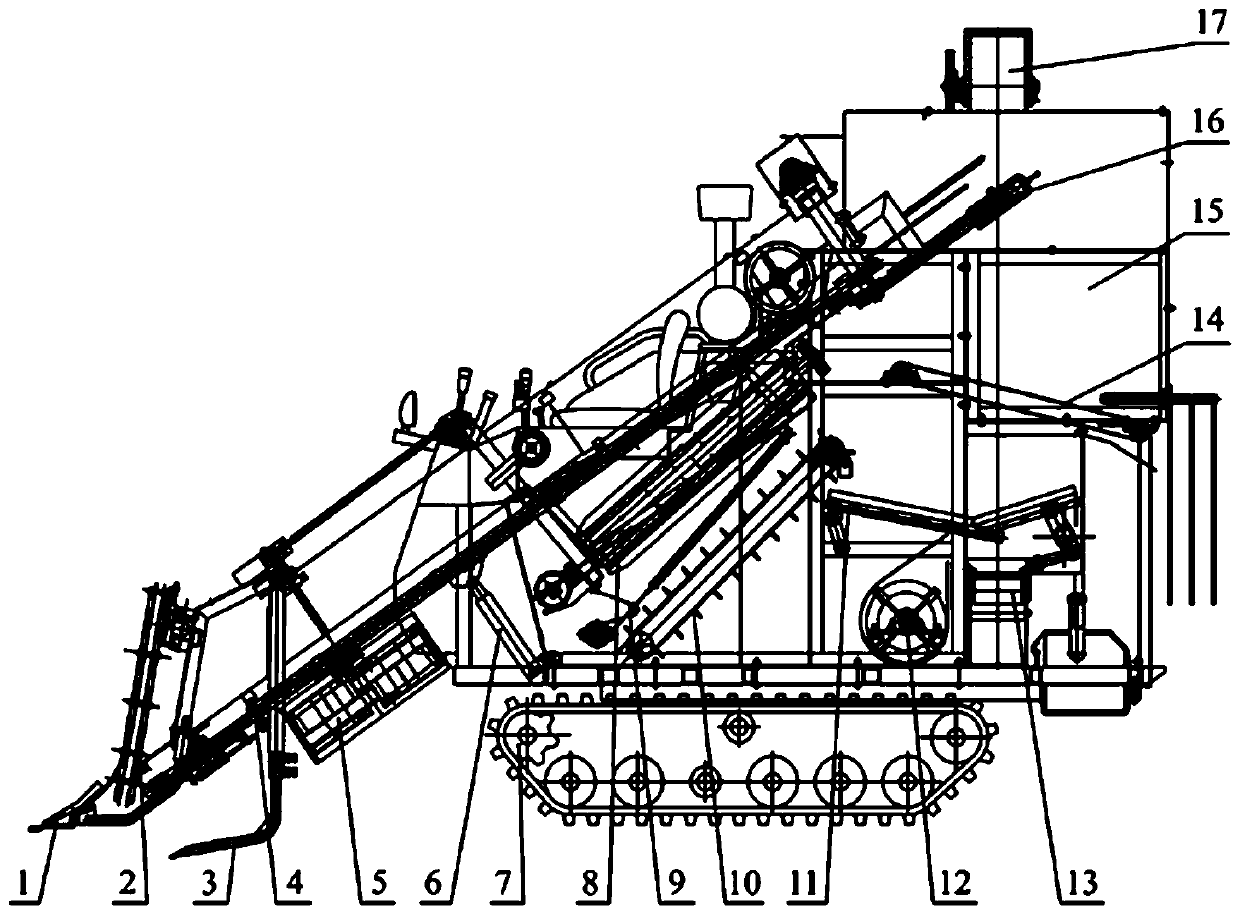

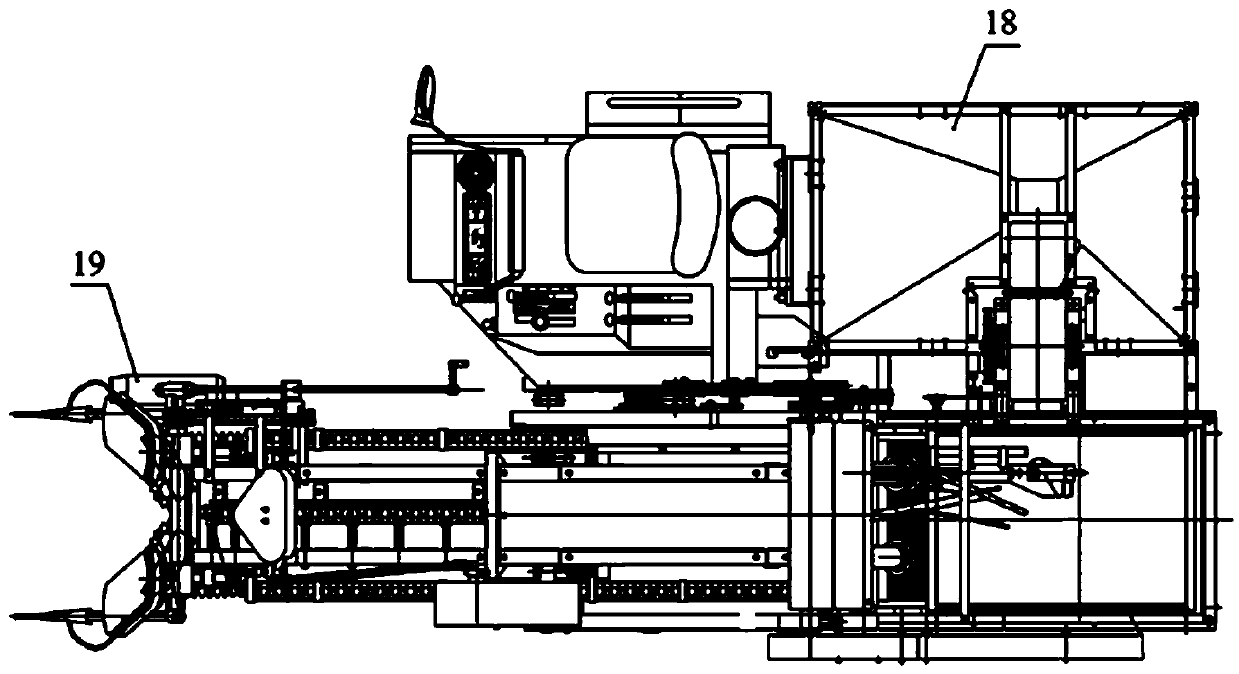

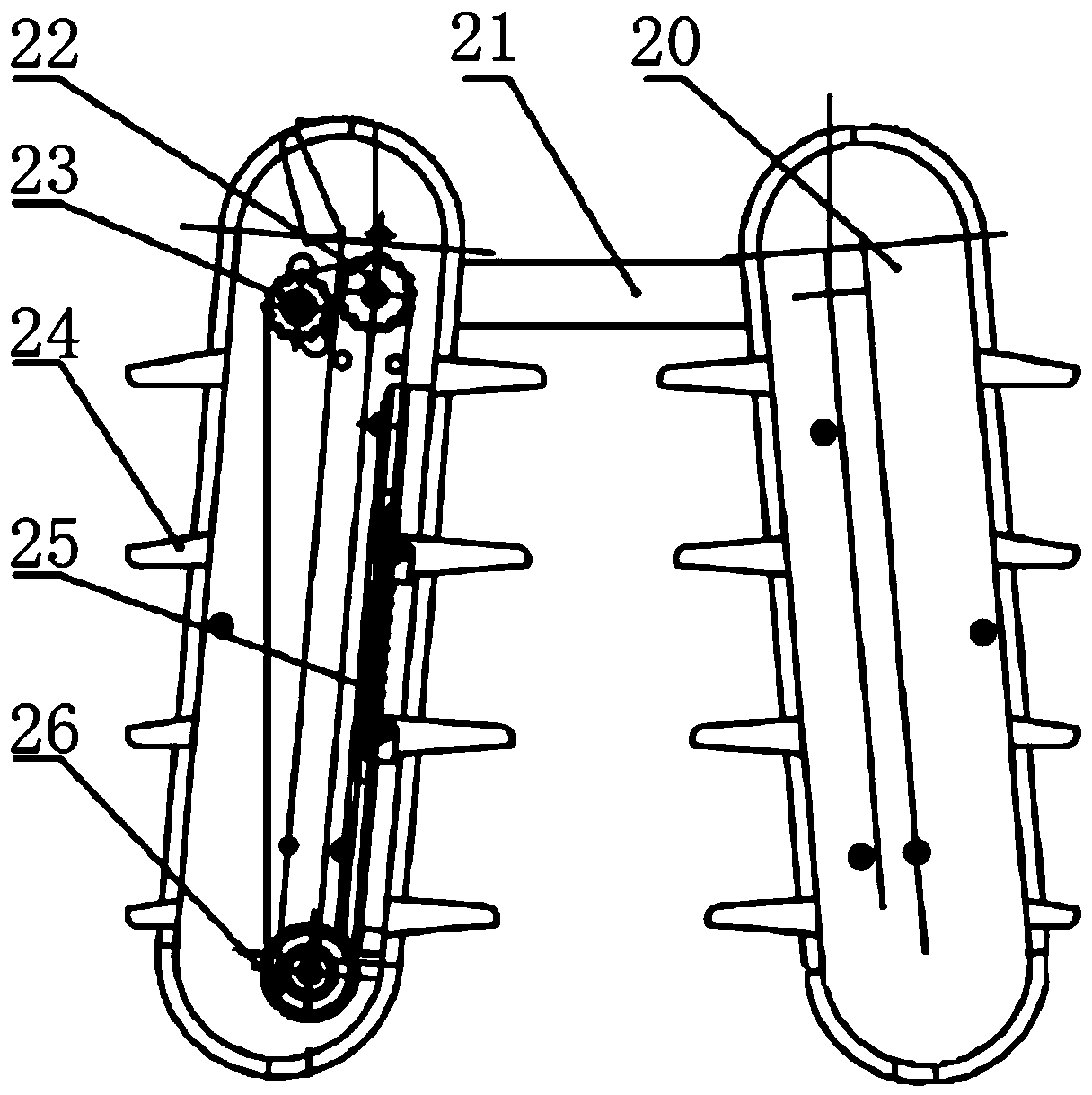

[0022] exist figure 1 , 2 Medium, including grain divider, grain raiser, digging shovel, grain removal conveyor chain, soil cleaner, hydraulic lifting cylinder, rubber crawler chassis, fruit picking roller, elastic curtain, scraper conveyor belt, cleaning screen, fan, horizontal conveying Belt, vine conveyor belt, main frame, vine throwing chain, vertical hoist, fruit collection box, depth limit device, when the harvester advances, the grain divider (1) and the grain lifter (2) will move within the working width The peanut plants are separated from the two sides and lifted up. At the same time, the digging shovel (3) cuts off the main root of the peanut and loosens the soil. Then the plants enter the reel conveyor chain (4), are pulled up and clamped and transported backwards. A soil cleaner (5) is provided at the bottom of the front conveying section to remove sand from the roots of the plants. When the plants are transported to the fruit picking section, the fruit pods are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com