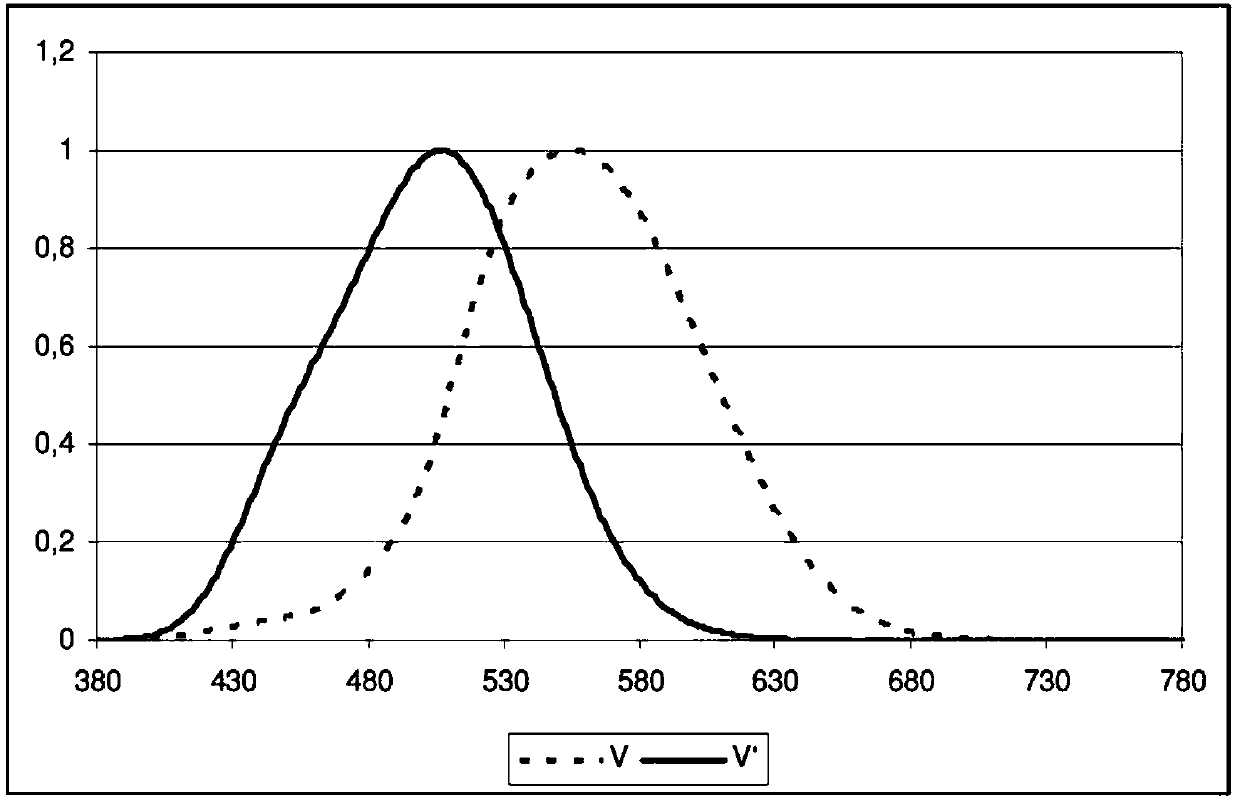

Optical article comprising an antireflective coating in the visible region for low luminance conditions

一种减反射涂层、低折射率层的技术,应用在涂层、光学、光学部件等方向,能够解决暗视觉不准确等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0127] 1. General procedure

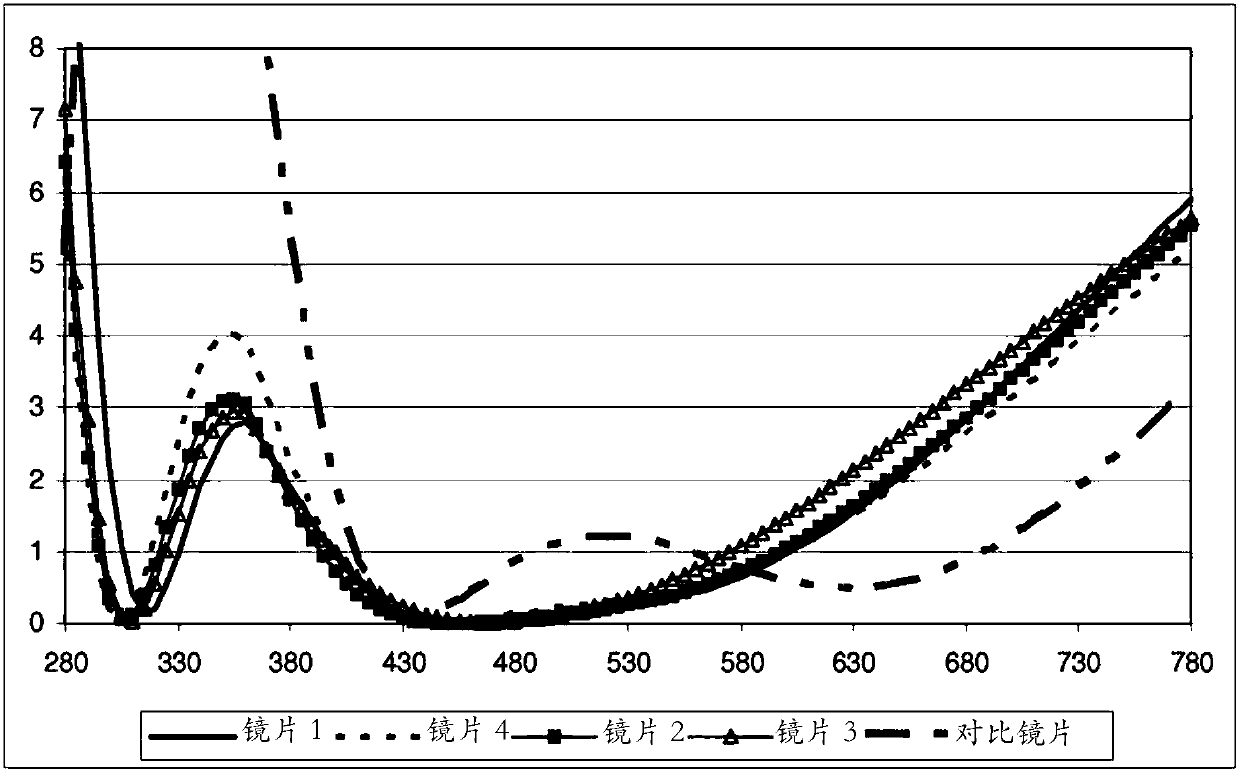

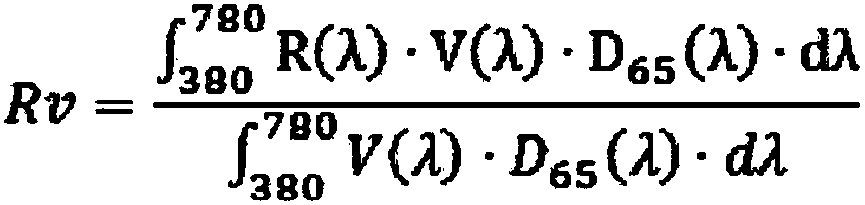

[0128] Optical articles according to the invention were designed, produced and tested with the goal of achieving a minimum Rv'.

[0129] The optical article used in the examples according to the invention included a lens substrate having a diameter of 65 mm, 1.50 (by made), 1.60 (by made) or 1.67 (by made), and a focal power of -2.00 diopters, coated with a hardcoat index-matched to the underlying substrate and coated on the front with an anti-reflective coating of the present invention (see Table 1 ). For lenses 1 to 3, the HI sheet closest to the substrate is composed of a first SiO layer L1 and a second TiO 2 Layers made of double layer. For lens 4, the HI sheet closest to the substrate is a single TiO 2 Floor.

[0130] For comparison purposes, another optical article was prepared with an antireflection coating according to the prior art. This comparative lens includes the following lens substrate: The lens substrate has a diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorptance | aaaaa | aaaaa |

| absorptance | aaaaa | aaaaa |

| absorptance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com