Dry etching method

A dry etching and etching rate technology, applied in semiconductor devices, electrical components, transistors, etc., can solve problems such as inability to guarantee dry etching quality and other thin film damages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

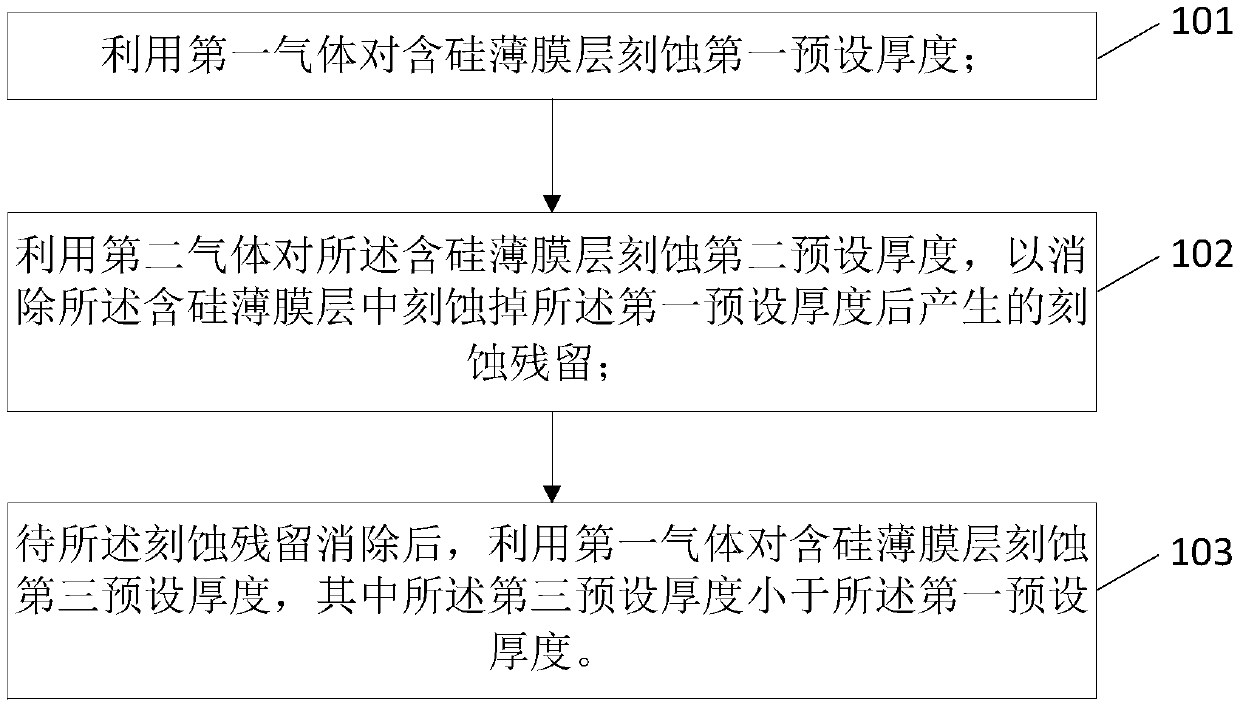

[0047] An embodiment of the present invention provides a dry etching method, including:

[0048] 70% of the thickness of the silicon-containing film layer was etched away by chlorine gas and sulfur hexafluoride gas at a pressure of 45 mTorr, wherein the mass ratio of sulfur hexafluoride gas to chlorine gas was 1:30.

[0049] 20% of the thickness of the silicon-containing thin film layer was etched away by oxygen gas and carbon tetrafluoride gas at a pressure of 45 mTorr, wherein the mass ratio of oxygen gas and carbon tetrafluoride gas was 1:5, and the over-etching amount was 10%.

[0050] 10% of the thickness of the silicon-containing film layer was etched away by chlorine gas and sulfur hexafluoride gas at a pressure of 45 mTorr, wherein the mass ratio of sulfur hexafluoride gas to chlorine gas was 1:30, and the over-etching amount was 20%.

[0051] Wherein, the above-mentioned dry etching temperature is 20 degrees Celsius.

Embodiment 2

[0053] An embodiment of the present invention provides a dry etching method, including:

[0054] 55% of the thickness of the silicon-containing film layer was etched away by chlorine gas and sulfur hexafluoride gas at a pressure of 30 mTorr, wherein the mass ratio of sulfur hexafluoride gas to chlorine gas was 1:30.

[0055] 30% of the thickness of the silicon-containing thin film layer was etched away by using oxygen gas and carbon tetrafluoride gas at a pressure of 30 mTorr, wherein the mass ratio of oxygen gas and carbon tetrafluoride gas was 1:1.5, and the over-etching amount was 20%.

[0056] Using chlorine gas and sulfur hexafluoride gas at a pressure of 30 mTorr to etch away 15% of the thickness of the silicon-containing thin film layer, wherein the mass ratio of sulfur hexafluoride gas to chlorine gas is 1:20, and the over-etching amount is 15%.

[0057] Wherein, the above-mentioned dry etching temperature is 30 degrees Celsius.

Embodiment 3

[0059] An embodiment of the present invention provides a dry etching method, including:

[0060] 75% of the thickness of the silicon-containing film layer was etched away by chlorine gas and sulfur hexafluoride gas at a pressure of 30 mTorr, wherein the mass ratio of sulfur hexafluoride gas to chlorine gas was 1:20.

[0061] 15% of the thickness of the silicon-containing thin film layer was etched away by using oxygen gas and carbon tetrafluoride gas at a pressure of 30 mTorr, wherein the mass ratio of oxygen gas and carbon tetrafluoride gas was 1:10, and the over-etching amount was 10%.

[0062] 10% of the thickness of the silicon-containing thin film layer was etched away by chlorine gas and sulfur hexafluoride gas at a pressure of 30 mTorr, wherein the mass ratio of sulfur hexafluoride gas to chlorine gas was 1:20, and the over-etching amount was 15%.

[0063] Wherein, the above-mentioned dry etching temperature is 25 degrees Celsius.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com