Casting type asphalt isolating agent, preparation method and paving method thereof

An asphalt mixture, pouring technology, which is applied to the coagulation pavement, buildings, roads and other directions of on-site paving, can solve the problems of poor quality of asphalt concrete pavement, unfavorable health of workers, polluted pavement, etc., and saves the application of release agent. time, reduce quality impact, and avoid contamination effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

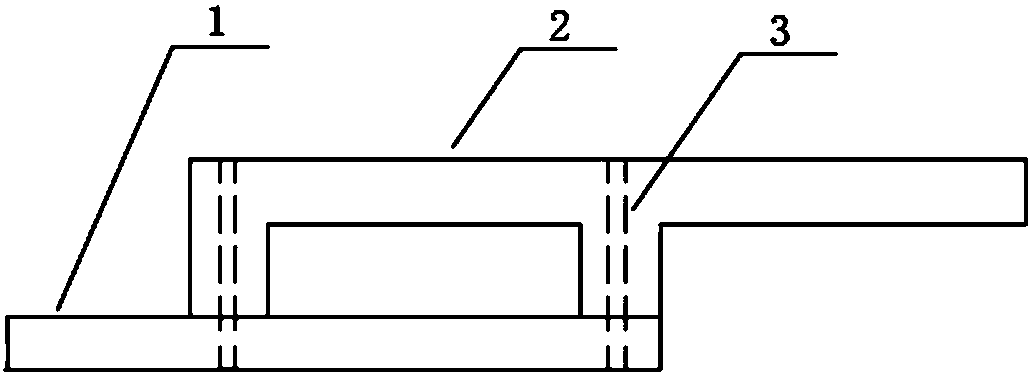

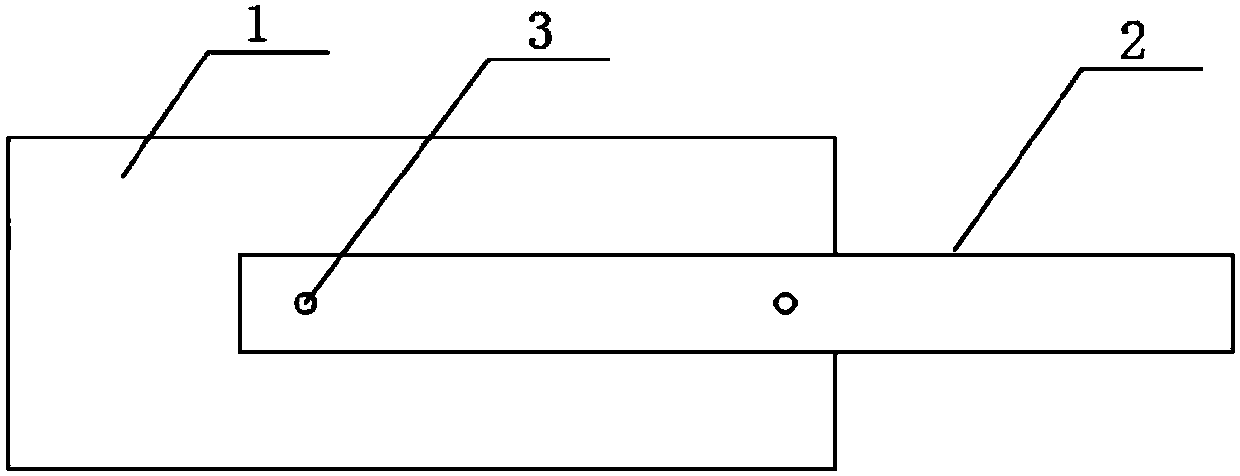

[0031] Embodiment 1: as figure 1 and figure 2 as shown,

[0032] A castable asphalt mixture release agent, which includes the following components: 150N base oil, 2,6-di-tert-butyl-p-cresol and polyether modified silicone oil, which are mixed according to the mass ratio of 100:0.02:2 Prepare the release agent.

[0033] A preparation method of castable asphalt mixture release agent, comprising the following steps:

[0034] Step 1) Weigh 150N base oil, 2,6-di-tert-butyl-p-cresol, and polyether-modified silicone oil at a ratio of 100:0.02:2, and then weigh 2,6-di-tert-butyl-p-cresol and polyether modified silicone oil are sequentially added to the container containing 150N base oil;

[0035] Step 2) Stir continuously for 10 minutes at a rotational speed of 100r / min to obtain a uniformly dispersed release agent with low surface energy.

[0036] A paving method of castable asphalt mixture, using red oak to prepare a 25cm long, 10cm wide plaster 1, and a 30cm long handle 2, th...

Embodiment 2

[0040] Embodiment 2: as figure 1 and figure 2 as shown,

[0041] A pourable asphalt mixture release agent, which includes the following components: 150N base oil, dibutyl hydroxytoluene and fluoroalkyl polyether modified polysiloxane, and is carried out according to the mass ratio of 100:0.1:1 Mix to make a release agent.

[0042] A preparation method of castable asphalt mixture release agent, comprising the following steps:

[0043]Step 1) Weigh 150N base oil, dibutyl hydroxytoluene, and fluoroalkyl polyether modified polysiloxane at a ratio of 100:0.1:1, and then weigh dibutyl hydroxytoluene and fluoroalkyl Add polyether-modified polysiloxane into a container containing 150N base oil;

[0044] Step 2) Stir continuously for 15 minutes at a rotational speed of 60r / min to obtain a uniformly dispersed release agent with low surface energy.

[0045] A paving method of castable asphalt mixture, using red oak to prepare a 25cm long, 10cm wide plaster 1, and a 30cm long handle...

Embodiment 3

[0049] Embodiment 3: as figure 1 and figure 2 as shown,

[0050] A castable asphalt mixture release agent comprises the following components: 250N base oil, dibutyl hydroxytoluene and fatty alcohol polyvinyl chloride ether, which are mixed according to the mass ratio of 100:0.08:2.0 to prepare the release agent.

[0051] A preparation method of castable asphalt mixture release agent, comprising the following steps:

[0052] Step 1) Weigh 250N base oil, dibutyl hydroxytoluene, and fatty alcohol polyvinyl chloride ether at a ratio of 100:0.08:2.0, then add dibutyl hydroxytoluene and fatty alcohol polyvinyl chloride ether to the 250N base oil container;

[0053] Step 2) Stir continuously for 13 minutes at a rotational speed of 90r / min to obtain a uniformly dispersed release agent with low surface energy.

[0054] A paving method of castable asphalt mixture, using white oak to prepare a plaster 1 with a length of 20 cm and a width of 10 cm, and a handle 2 with a length of 30 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com