Extrusion molding structure using multiple cylinders

An extrusion molding and multi-cylinder technology, which is applied in the direction of stamping machines, presses, manufacturing tools, etc., can solve the problems of not meeting the requirements of molding, easy rebound, and damage to molding quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

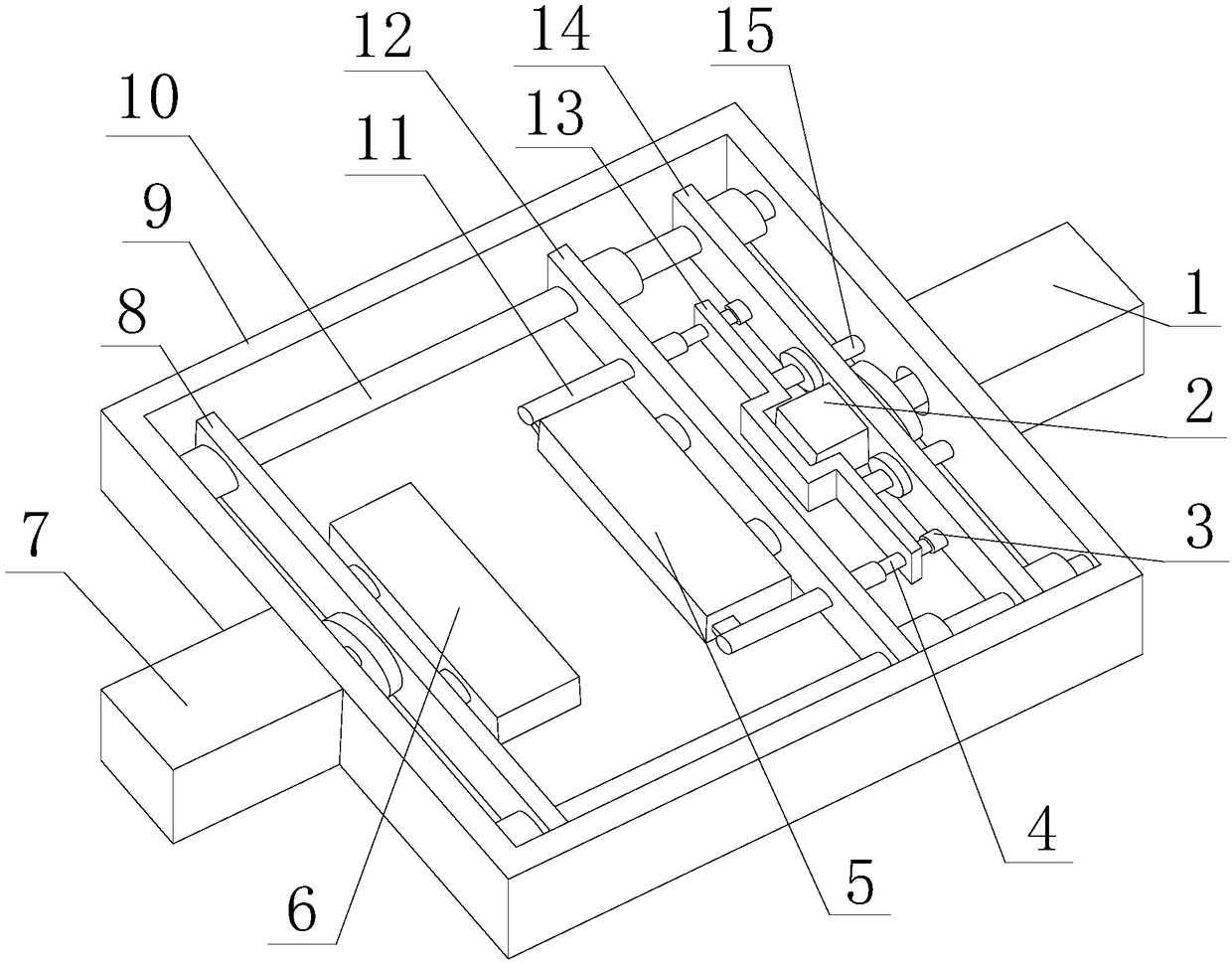

[0021] Such as figure 1 As shown, the extrusion molding structure adopts multiple cylinders, including a hollow support frame 9 inside, and cylinder one 1 and cylinder two 7 are arranged on the outside of the support frame 9, and cylinder one 1 and cylinder two 7 are respectively installed on the support On the symmetrical side wall of the frame 9, the piston rod of the cylinder one 1 and the piston rod of the cylinder two 7 pass through the support frame 9 and communicate with the cavity inside the support frame 9 respectively, and in the cavity of the support frame 9, parallel cylinders are arranged. A pair of guide mechanism one 10 and a pair of guide mechanism two 15, and the two ends of guide mechanism one 10 are respectively fixed with the wall surface that cylinder one 1 or cylinder two 7 are installed, and the outer wall of guide mechanism one 10 is respectively covered with mutually parallel Installing plate one 14, installing plate two 12 and installing plate three 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com