Manual quick changing device for working tools of roadway repairing machine and operation method thereof

A technology of repairing machine and rotating device, applied in the direction of manufacturing tools, hand-held tools, etc., can solve the problems that roadway repairing machines cannot meet operating requirements, reliability and stability are not high, and hydraulic cylinders are easily damaged, and the scope of application can be improved. and operation ability, improving construction efficiency, and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical scheme of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand and implement the present invention, but the examples given are not intended to limit the present invention.

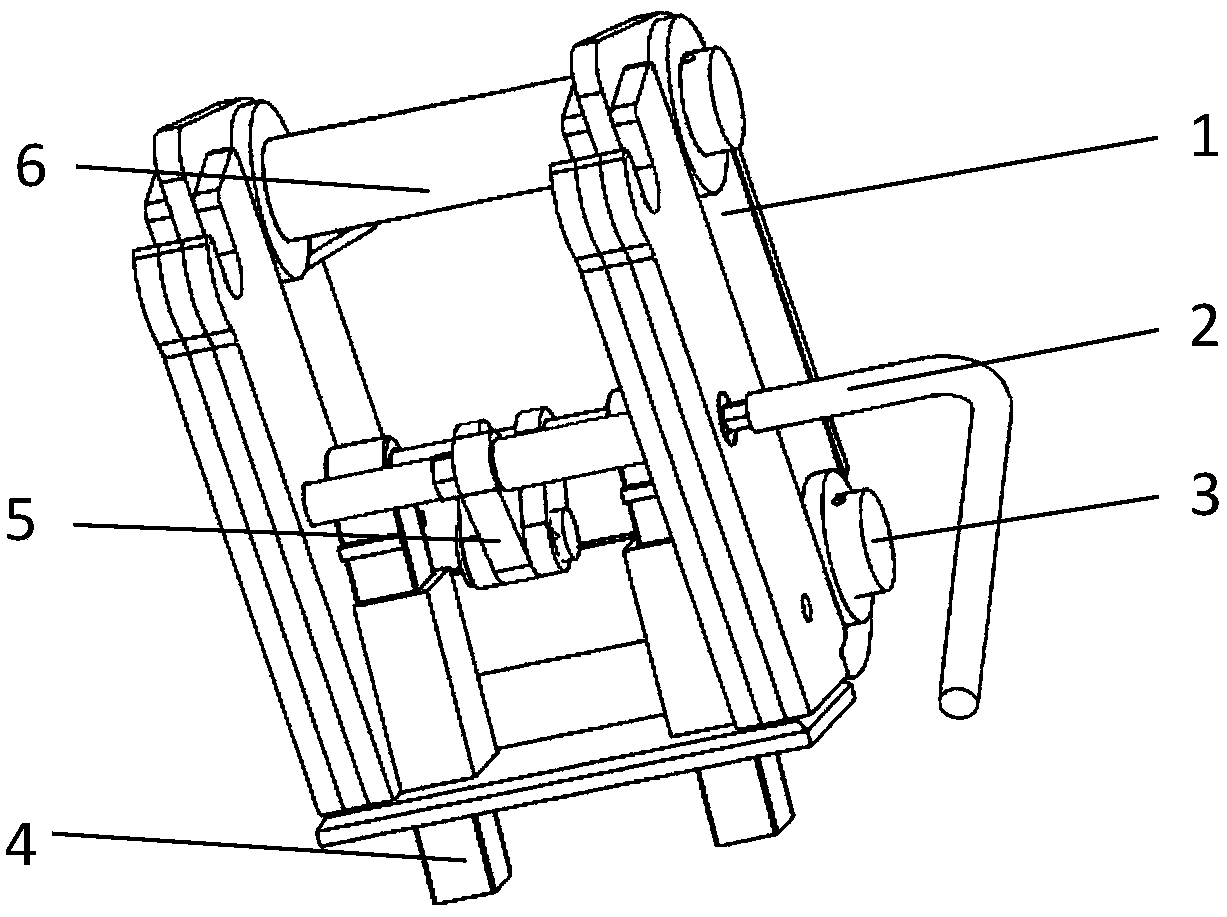

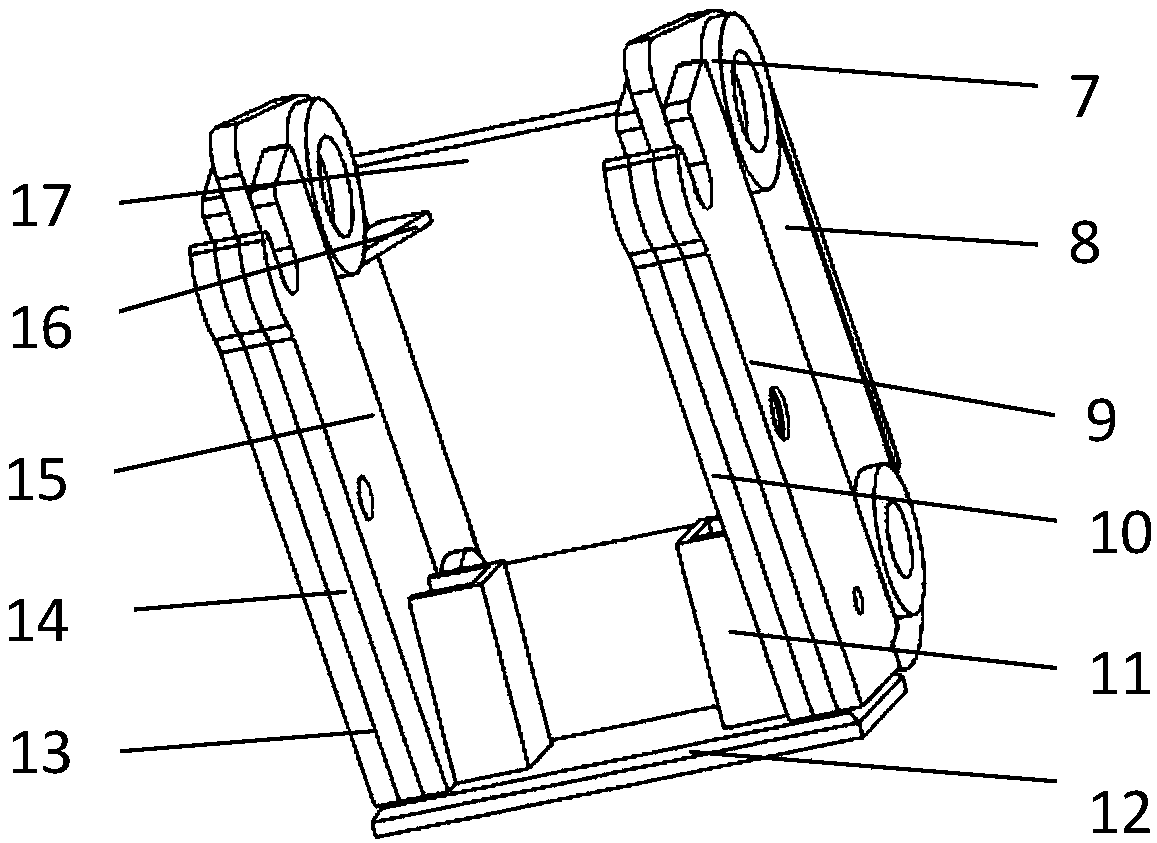

[0029] see figure 1 , shows a manual quick change device for roadway repair machine working tools of the present invention, which may include a connecting housing 1, a socket wrench 2, a first pin shaft 3, a positioning block 4, a rotating device 5 and a second pin shaft 6 , the first pin shaft 3 and the second pin shaft 6 are respectively arranged on the upper and lower parts of the connecting housing 1, the rotating device 5 is located in the middle part of the connecting housing 1, and the socket wrench 2 is detachably connected The positioning block 4 is slidably located on the connecting housing 1 and driven by the rotating device 5 and is drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com