Novel pot punching machine

A technology for punching machines and pots, applied in the field of punching machines, can solve the problems of low efficiency, time-consuming and laborious, unable to meet the diversified production needs of workshops, etc., and achieve the effect of easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing and example.

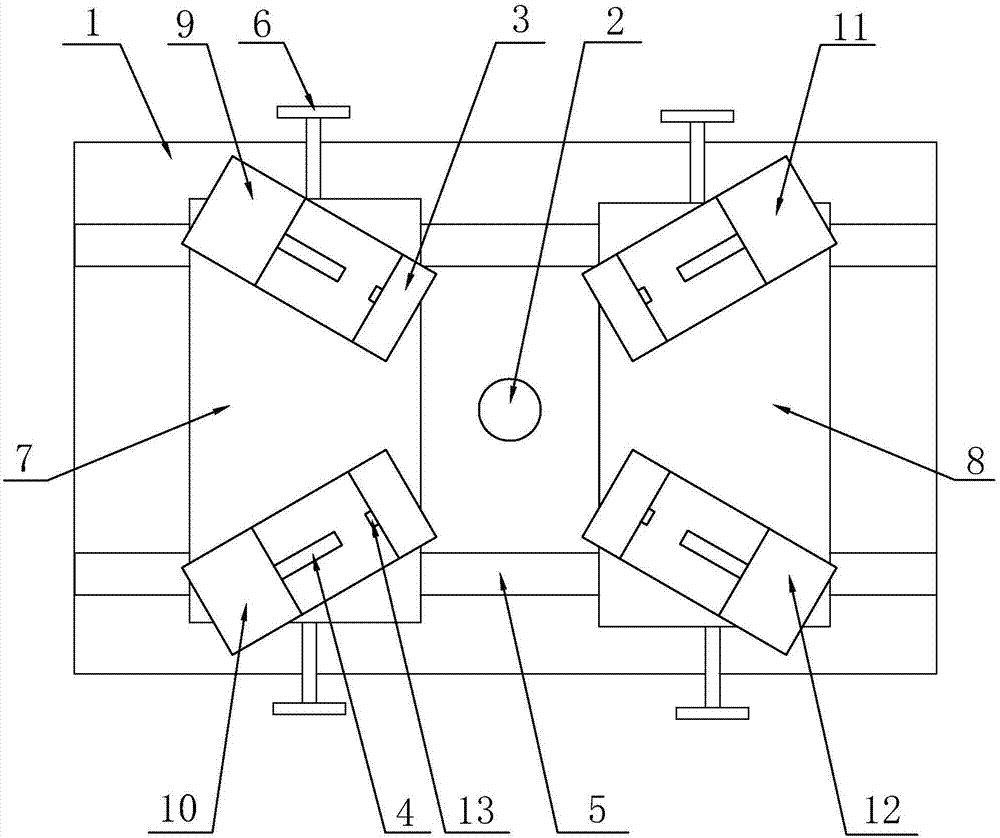

[0016] Such as figure 1 As shown, the present invention provides a new type of pot punching machine, including a machine table 1, which is provided with a plurality of clamps for fixing the pot body, and a positioning column 2 is erected at the center of the machine table 1. The direction is arranged around the positioning column 2, and the fixture is movably installed on the machine table 1. The fixture is provided with a limit block 3 for resisting the pot body and a drilling bit 4 for punching the pot body. On the limit block 3 A boss 13 corresponding to the matching drilling bit is provided, and the drilling bit 4 is detachably inserted on the fixture. Fixture position is easy to adjust like this, can be applicable to the pot body of different models to carry out punching, and can change and change perforating bit 4 quickly according to production requireme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com