Assembling line for building decoration material shell powder shredding and grinding production

A technology for building decoration materials and shell powder, which is applied in the direction of grain processing, etc., can solve the problems of uneven force, high labor intensity, and different powder particle sizes, and achieves reduced labor intensity, high work efficiency, and low labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

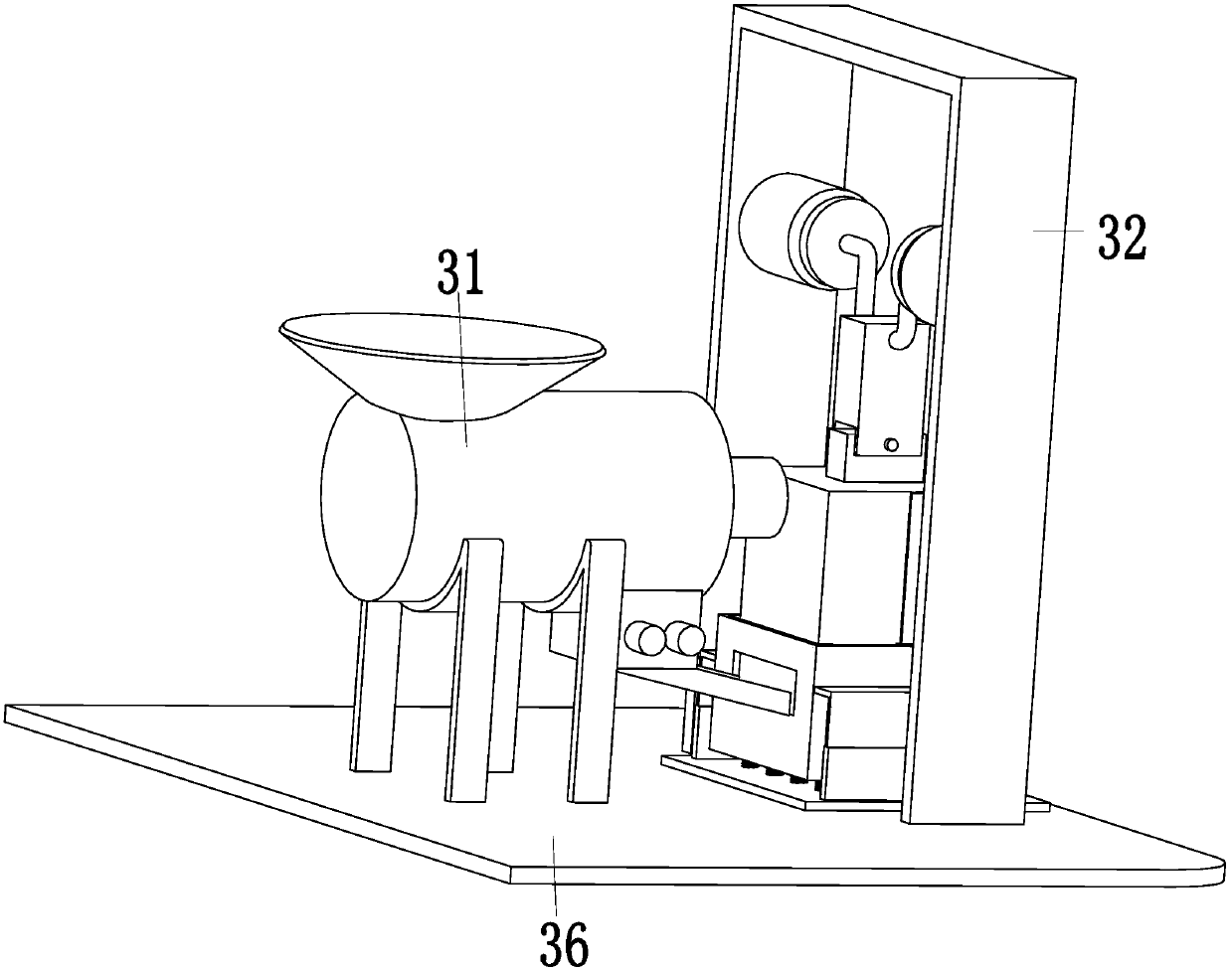

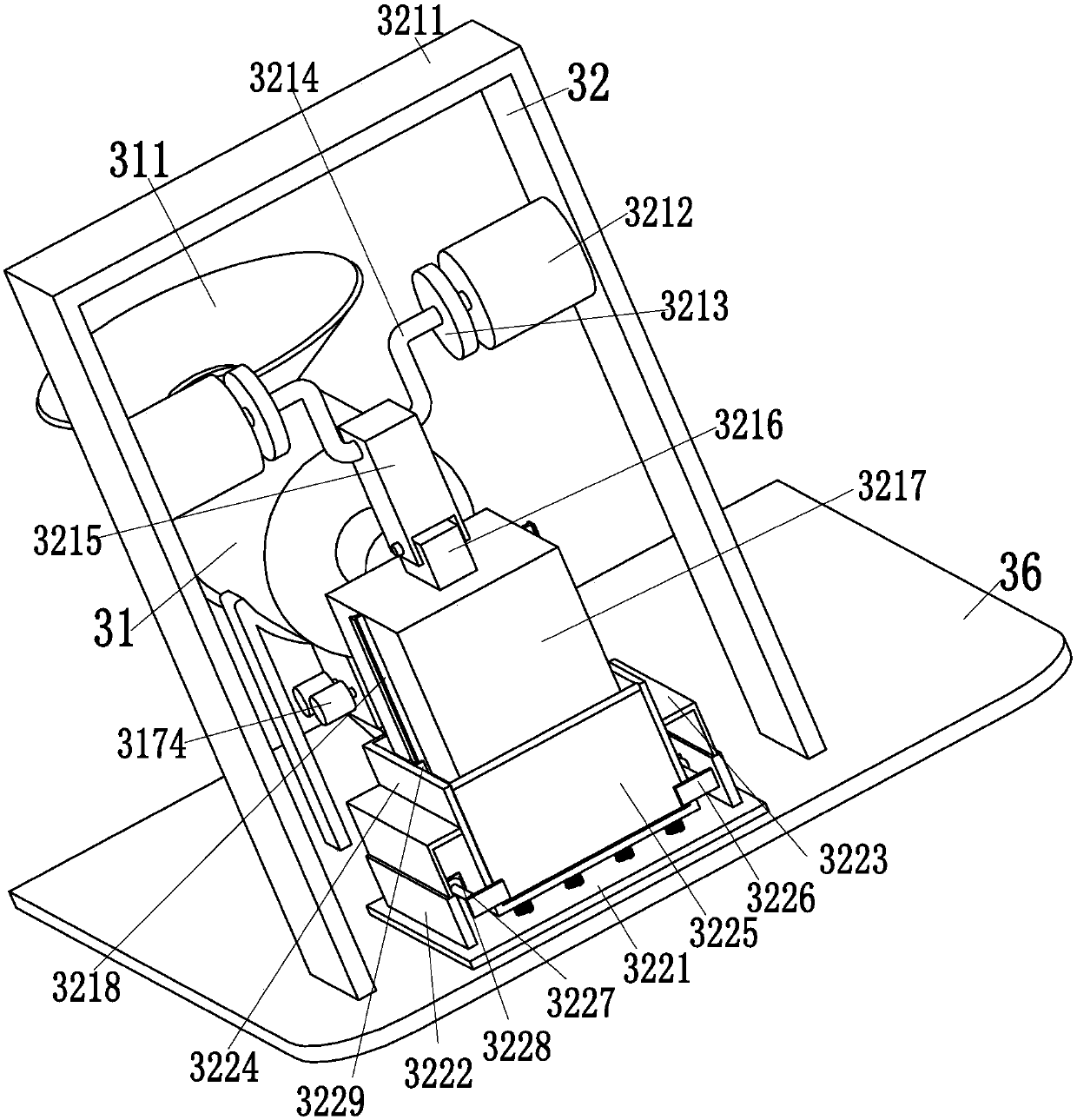

[0021] Such as Figure 1 to Figure 3As shown, in order to achieve the above object, the present invention adopts the following technical solutions: a production line for the crushing and grinding of building decoration material shell powder, including a base plate 36, a crushing mechanism 31 and a grinding mechanism 32, and the crushing mechanism 31 pairs The shell plays the role of cutting, and the grinding mechanism 32 plays the effect of reciprocating reloading and grinding to the shell. At the rear end, the crushing mechanism 31 and the grinding mechanism 32 cooperate to complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com