Vacuum stirring type ultrasonic wave dispersing breaking treatment tank

A technology of vacuum stirring and processing tank, applied in grain processing, dissolving, mixer and other directions, can solve problems such as affecting battery quality, insufficient fusion of carbon powder and conductive agent, etc., to achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

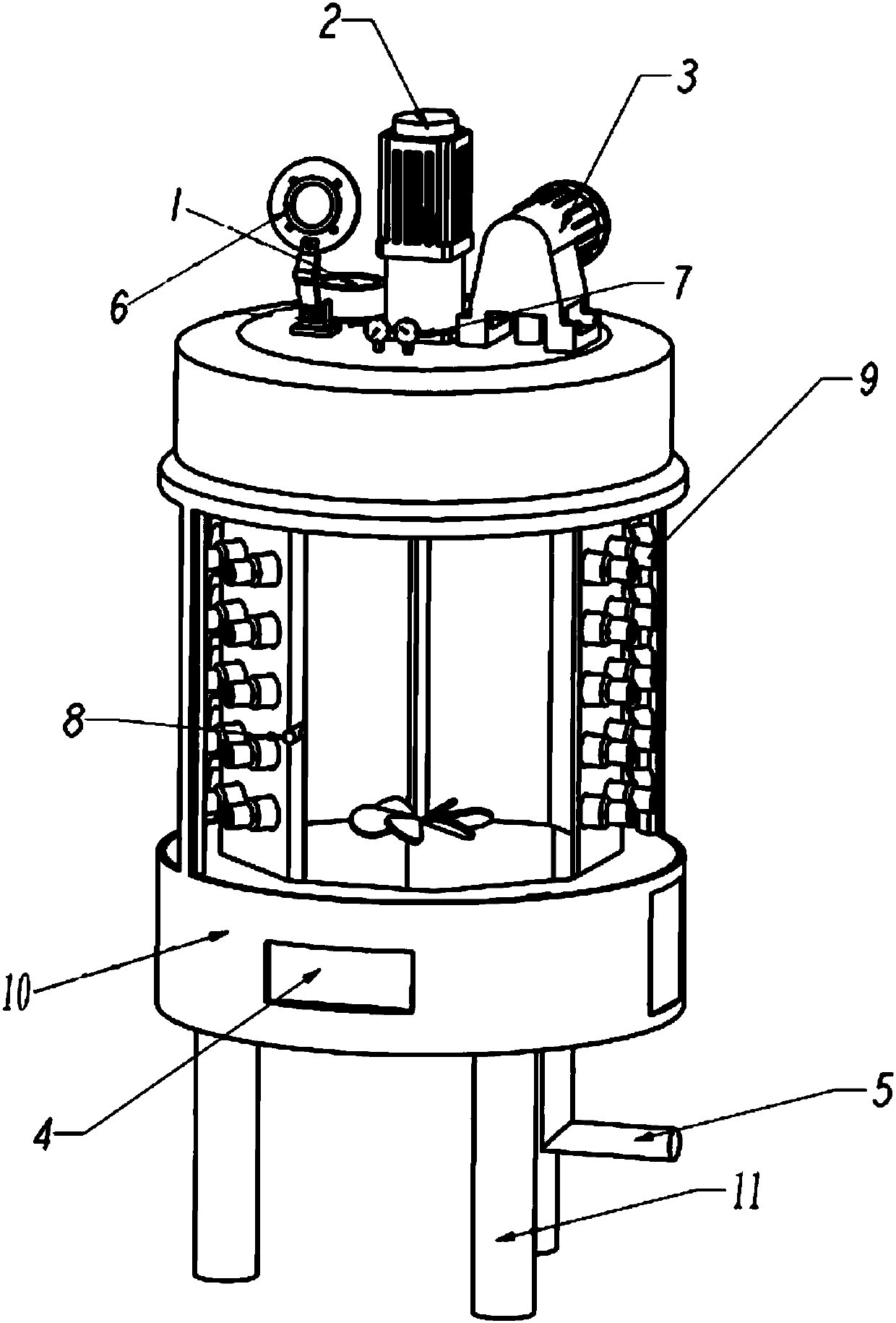

[0015] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings.

[0016] As shown in Figure 1, a vacuum agitation type ultrasonic dispersion and crushing treatment tank of an example of the present invention includes a treatment tank body 10, the top of the treatment tank body 10 is provided with a stirring motor 2 in the middle, and both sides of the stirring motor 2 are respectively provided with inlets 1 and a vacuum pump 3, a sealing cover 6 is movably arranged on the feed inlet 1, a discharge port 5 is arranged at the bottom of the processing tank body 10, and a number of ultrasonic vibrators 9 are arranged on the periphery of the processing tank body.

[0017] Wherein, the top of the processing tank body 10 is also provided with a vacuum gauge 7 for detecting the vacuum degree inside the processing tank.

[0018] Wherein, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com