A Finite Element Simulation Method of Bonding Behavior Between Prestressed Beam and Concrete

A technology of prestressed beam and bonding performance, which can be used in instruments, measuring devices, mechanical devices, etc., and can solve the problems of high testing cost and difficulty in meeting actual needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] Now using the technology of the present invention to the document "Secondary anchorage in post-tensionedbridge systems, Elie El Zghayar, Kevin R. Mackie. ACI Structural Journal. 2013, 110(4): 629-638." The effective bond length is The 470mm prestressed beam specimen was simulated. The simulation method of this example includes the following steps:

[0072] Step 1: Build a geometric model.

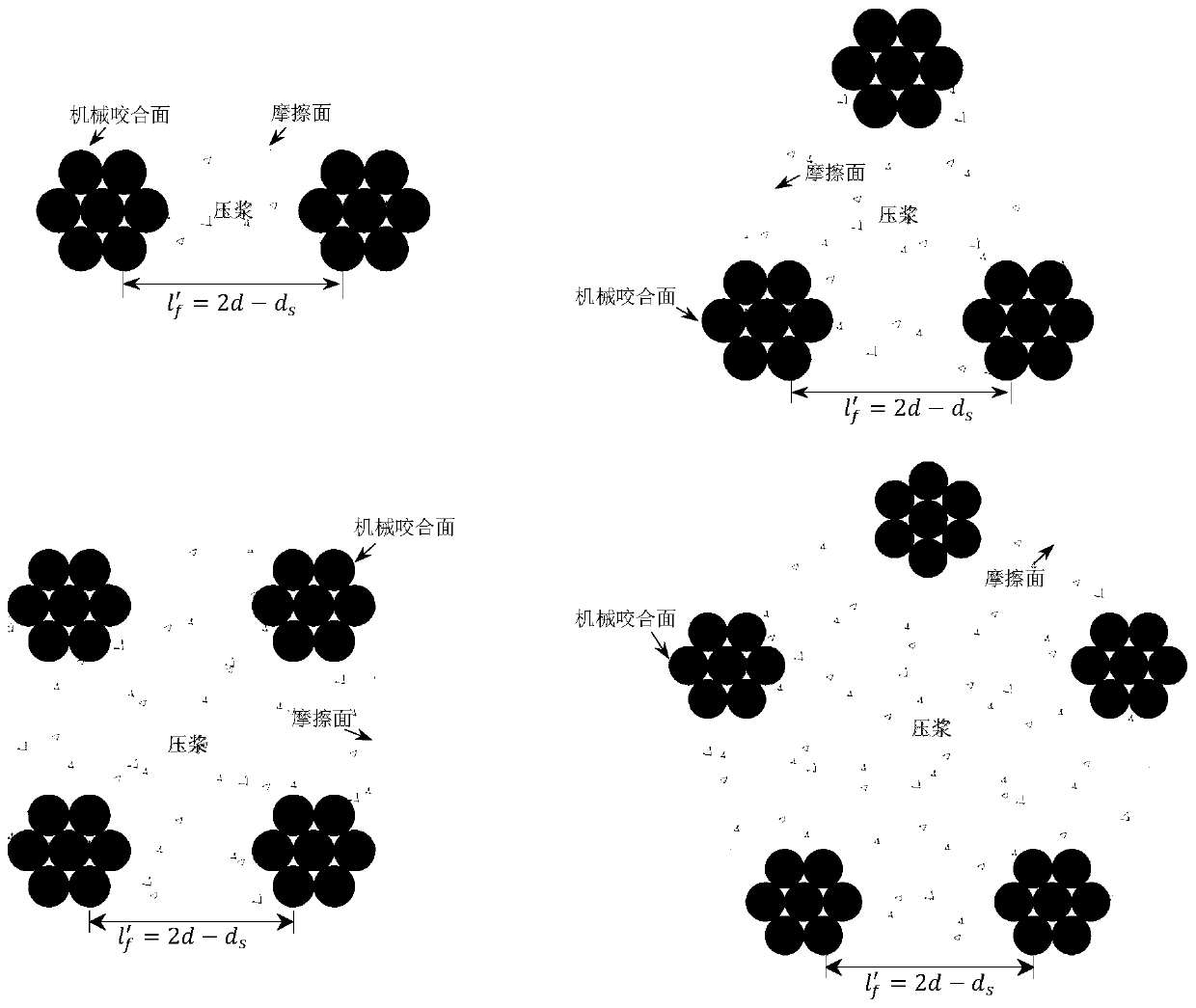

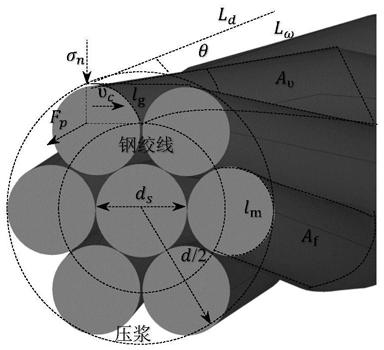

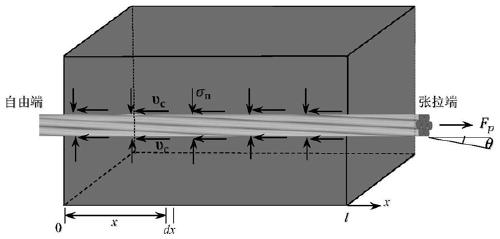

[0073] 1) Determine the geometric parameters of the structure. The geometric size of the test piece is 470mm×1981mm×610mm, using (Seven strands) steel strand, the extension length of the tension end is 250mm, and the extension length of the free end is 100mm. The specimen adopts a concrete cuboid with a strength of C50, a grouting material with a strength of 50MPa and ordinary steel bars of HRB400. The section characteristics and main parameters of the specimen are detailed in Image 6 , The mechanical properties of concrete and steel strands are shown in Table 1.

[0074] 2) Using ANSY...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com