True triaxial multifunctional large deep mine laneway model testing machine

A model test, multi-functional technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of no pressure water system, insufficient loading pressure, no pressure holding effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

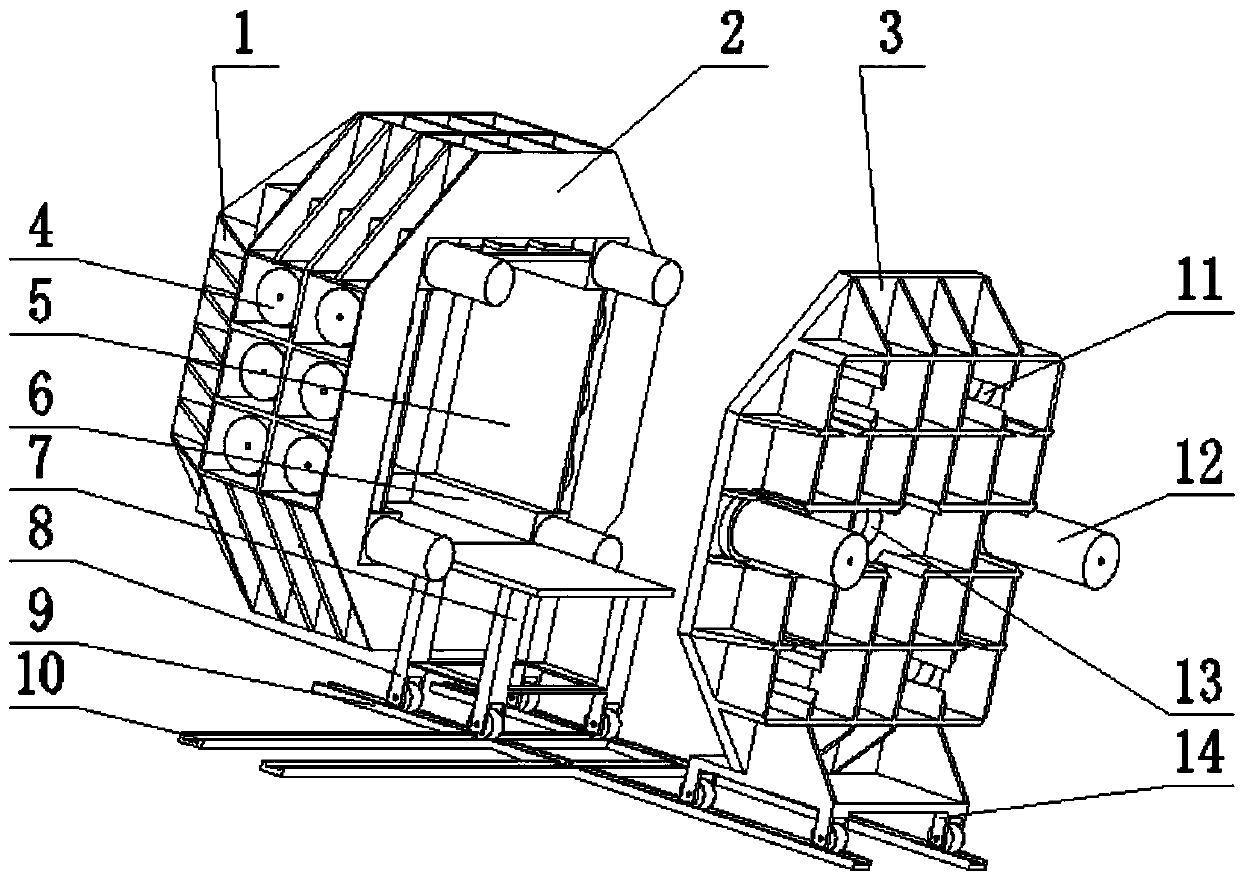

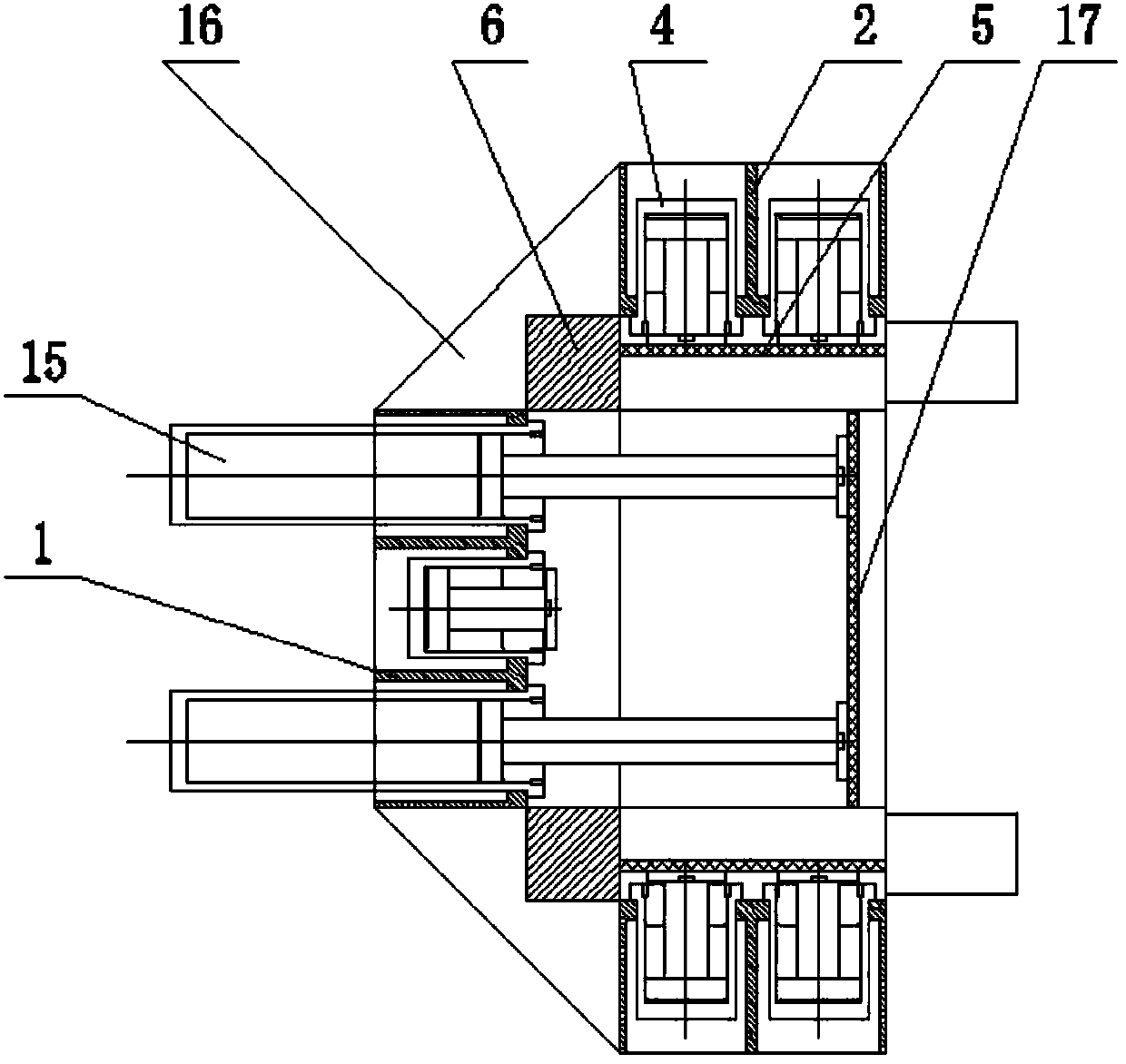

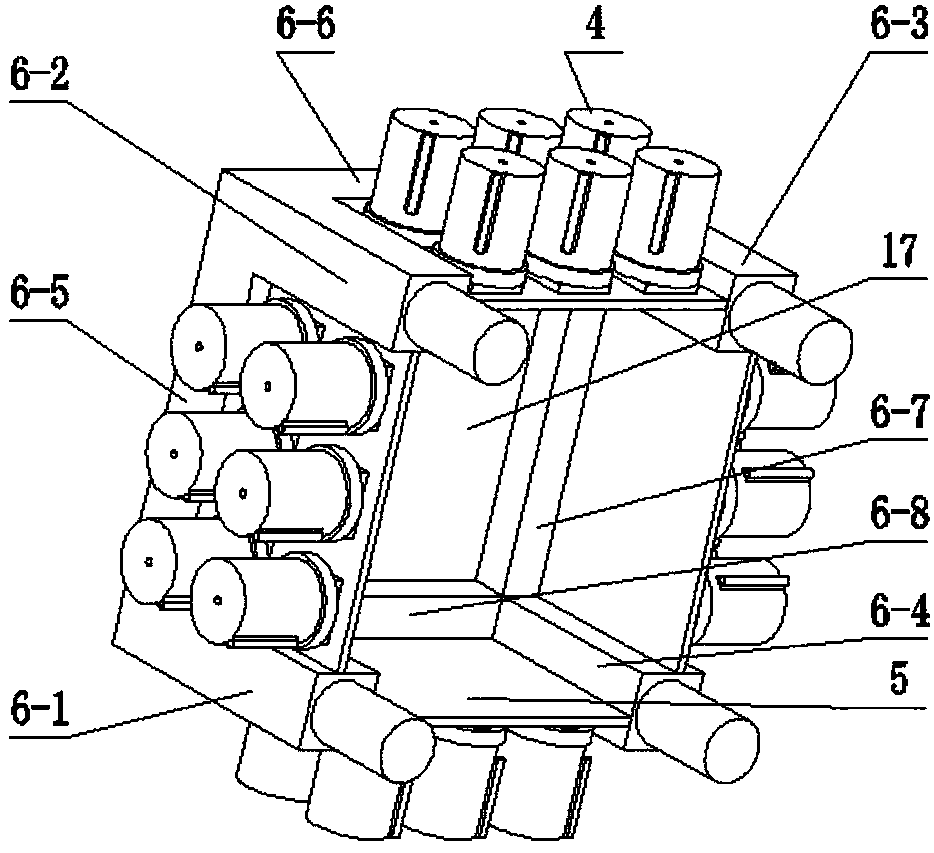

[0012] Reference attached Figure 1-3 : (1) Hydraulic actuators 4 are inlaid on the rear grid plate 1 and the four faces of the main frame 2 of the back shape, and the openings are arranged on the outside. The hydraulic actuators on the main frame 2 of the back shape The movable end of 4 is fixedly connected with the circumferential push plate 5; (2) Two upper and lower discharge cylinders 15 are embedded on the rear grid plate 1, and the movable end of the discharge cylinder 15 is fixedly connected with the discharge push plate 17; (3) The four longitudinal square columns 6-1, 6-2, 6-3, and 6-4 of the anti-interference frame 6 pass through the main frame 2 of the back shape, and their contact surfaces are welded and fixed, and the four circumferential square columns of the anti-interference frame 6 6-5, 6-6, 6-7, 6-8 are welded and fixed to the rear grid plate 1; (4) The reinforcing rib 16 is welded and fixed to the rear grid plate 1, and the main frame 2 of the round shape; (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com