Special radiator fan structure for microelectronic equipment

A heat dissipation fan and heat dissipation fan technology, applied to mechanical equipment, parts of pumping devices for elastic fluids, non-variable pumps, etc., can solve the problems of complex installation, easy to burn equipment, large volume, etc., and achieve faster The efficiency of heat dissipation, effective and uniform heat transfer, and the effect of increasing the heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

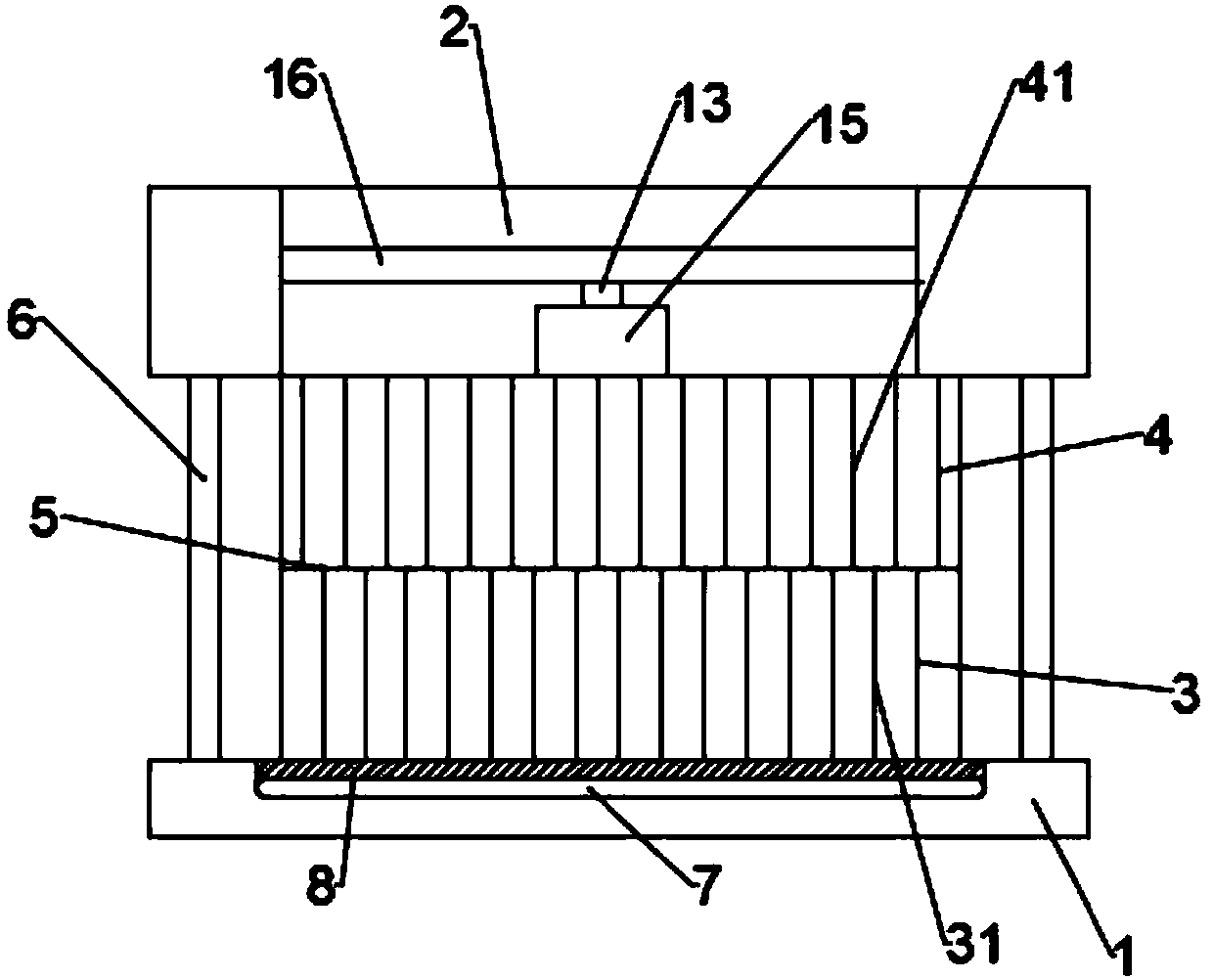

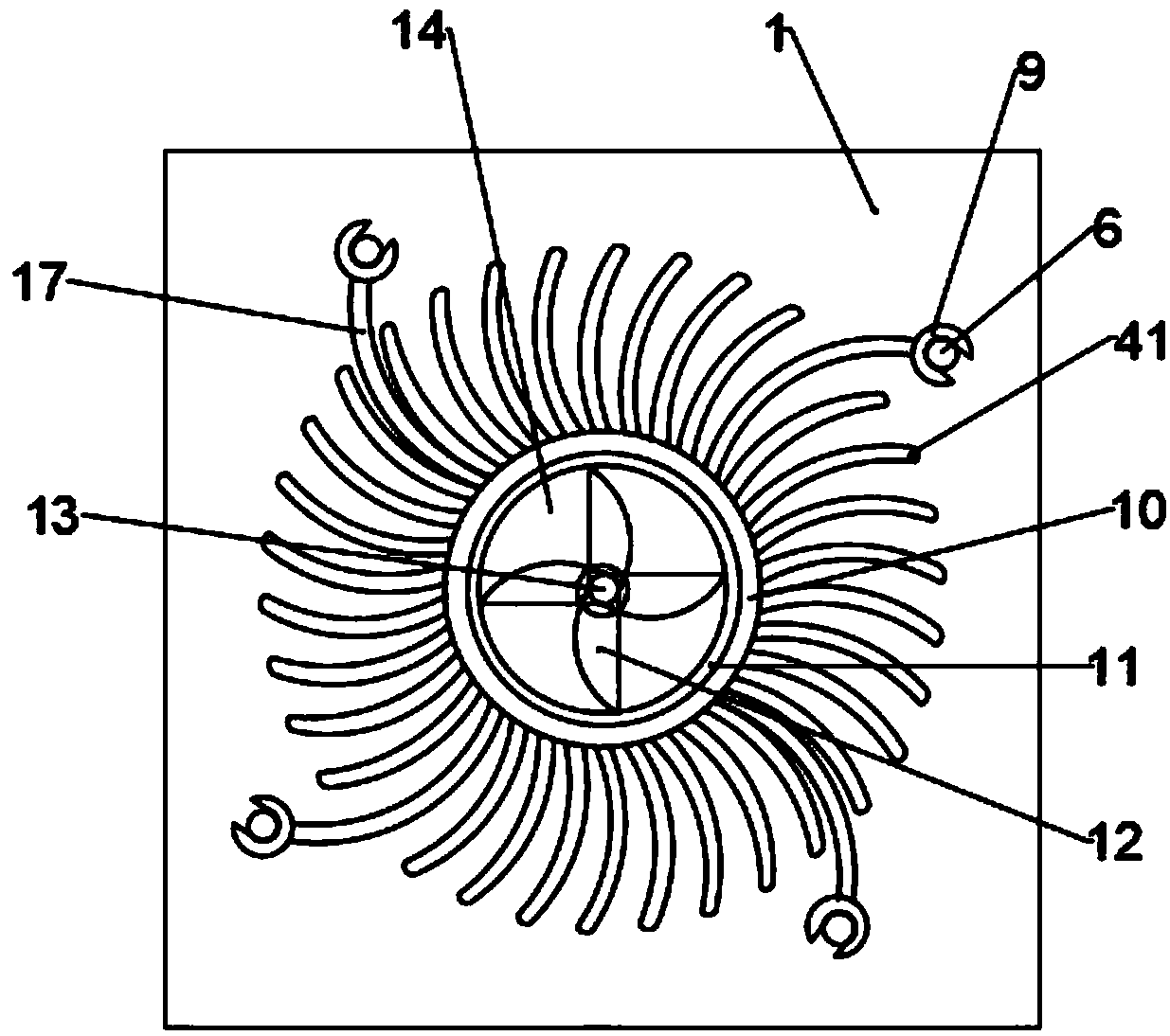

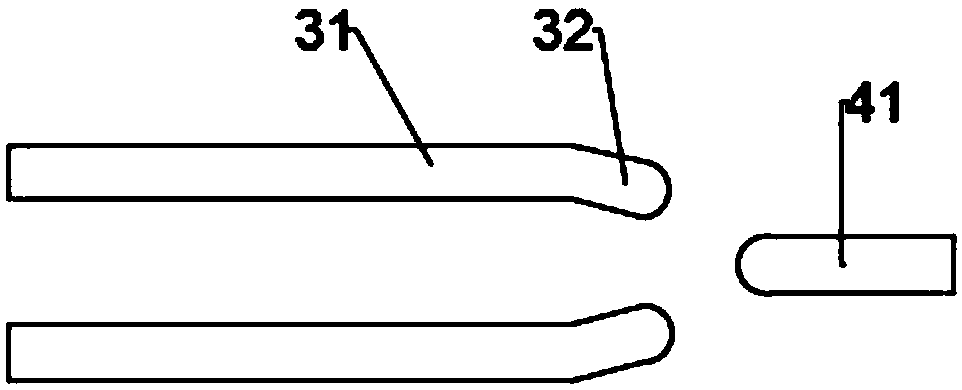

[0020] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention provides a special cooling fan structure for microelectronic equipment, including a bottom connecting plate 1, a fan 2, a first cooling fan 3 and a second cooling fan 4, and the bottom connecting plate 1 is installed on the first cooling fan 3 bottom, the first heat dissipation fan 3 and the second heat dissipation fan 4 are fixedly connected together, and the connection between the first heat dissipation fan 3 and the second heat dissipation fan 4 is provided with a flow gap 5, and the fan 2 is installed on the second On the top of the heat dissipation fan 4, a conduction ring 10 is arranged in the middle of the first heat dissipation fan 3 and the second heat dissipation fan 4, and the inner contact ring 11 is set inside the conduction ring 10, and the surface of the inner contact ring 11 is uniformly provided with Radiation sheet 111, and the radiation sheet 111 is embedded in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com