Normal sewing machine impurity removing device beneficial to safety and practicality

A lockstitch machine, a practical technology, is applied in sewing machine components, sewing equipment, textiles and papermaking, etc., can solve problems such as affecting physical health, and achieve the effects of simple structure, easy disassembly and assembly, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

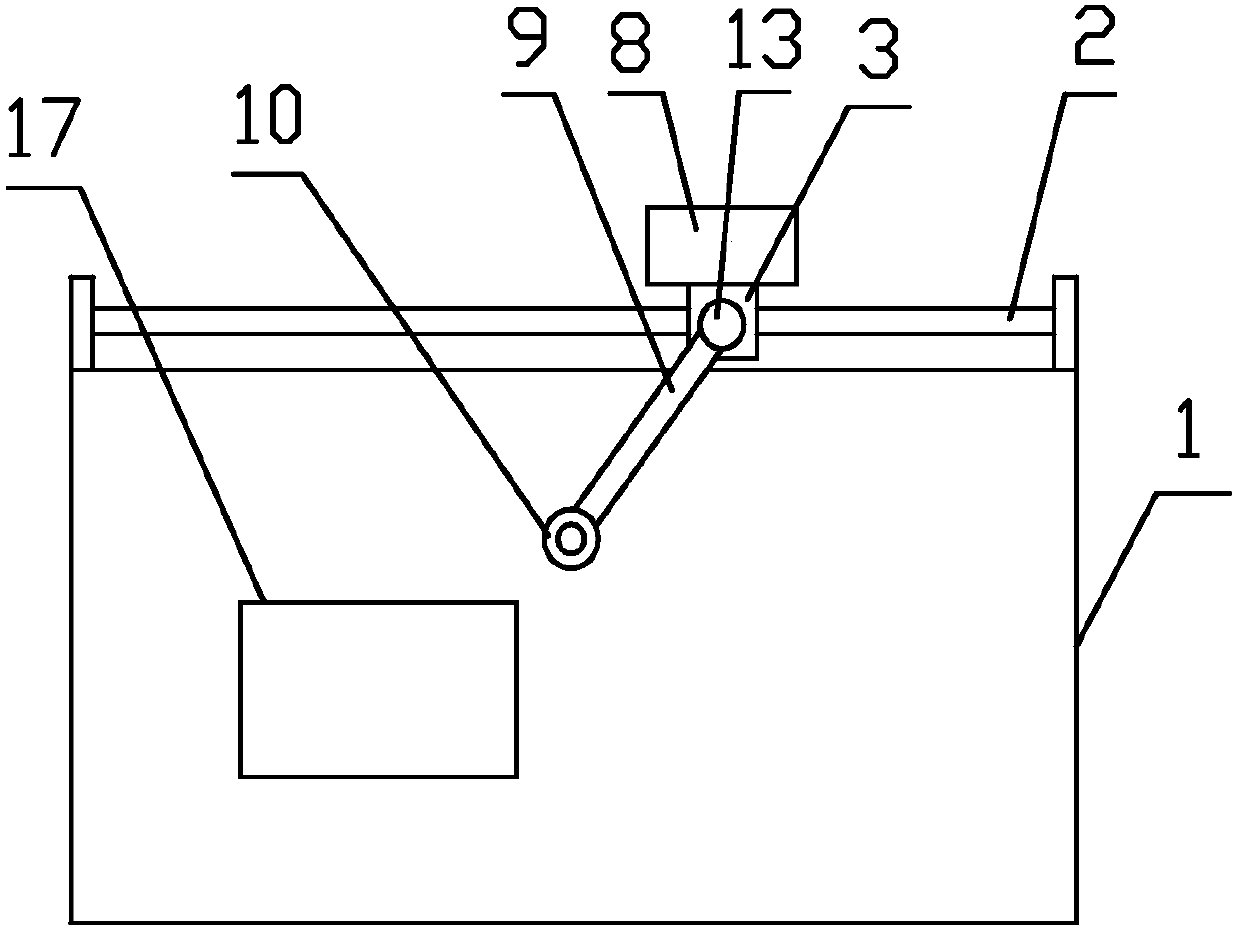

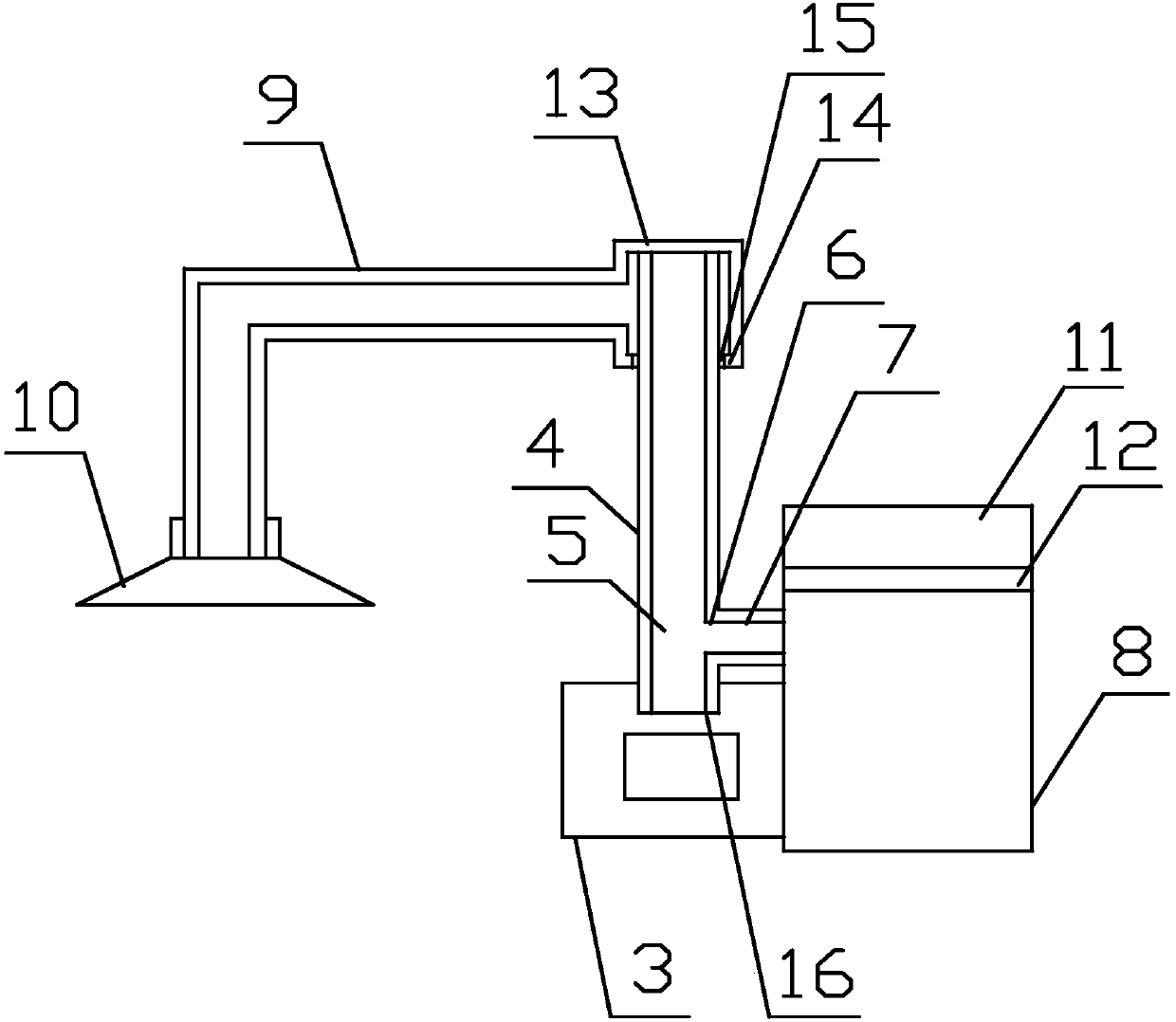

[0026] Such as figure 1 and figure 2 As shown, the present invention is conducive to a safe and practical lockstitch sewing machine impurity removal device, including a workbench rotating sleeve 1 rotating sleeve, the side wall of the workbench rotating sleeve 1 rotating sleeve is provided with a slide bar rotating sleeve 2 rotating sleeves, and the The long axis direction of the sliding bar rotating sleeve 2 rotating sleeve is arranged parallel to the long axis direction of the side wall; the sliding bar rotating sleeve 2 rotating sleeve is provided with a slider rotating along the sliding motion of the sliding bar rotating sleeve 2 rotating sleeve. Cover 3 rotating sleeves, the sliding block rotating sleeve 3 rotating sleeves are provided with vertical fixed column rotating sleeves 4 rotating sleeves; And the surface of the rotating sleeve 1 of the workbench is vertical; the rotating sleeve of the fixed column rotating sleeve 4 is provided with the rotating sleeve of the c...

Embodiment 2

[0028] Further improvement on the basis of Embodiment 1, the end of the second catheter rotating sleeve 9 rotating sleeve is connected with the fixed column rotating sleeve 4 rotating sleeve through the rotating sleeve rotating sleeve 13 rotating sleeve; the rotating sleeve rotating sleeve 13 rotating sleeve It is a cylindrical structure with one end open and one end closed in the axial direction, and the inner diameter of the rotating sleeve rotating sleeve 13 rotating sleeve is larger than the outer diameter of the fixed column rotating sleeve 4 rotating sleeve; the opening end inner wall of the rotating sleeve rotating sleeve 13 rotating sleeve protrudes along the circumferential direction There are ring plate rotating sleeves 14 rotating sleeves, the ring plate rotating sleeves 14 rotating sleeves are pressed and fixed by O-ring rotating sleeves 15 rotating sleeves and fixed column rotating sleeves 4 rotating sleeves; the rotating sleeve rotating sleeves 13 rotate The side ...

Embodiment 3

[0030] Further improvement on the basis of embodiment 2, the side wall of the rotating sleeve 8 of the collection chamber is fixed on the rotating sleeve of the slider rotating sleeve 3, and the rotating sleeve of the sliding block rotating sleeve 3 rotates the sleeve along the slide bar. sliding movement. The rotating sleeve 10 of the vacuuming device is sleeved on the top of the rotating sleeve 8 of the collection chamber, and the bottom of the rotating sleeve 8 of the collection chamber is provided with a discharge port. The slider rotating sleeve 3 is provided with a threaded mounting hole rotating sleeve 16 rotating sleeves, and the outer wall of the axial bottom end of the fixed column rotating sleeve 4 rotating sleeve is provided with an outer wall connected with the threaded mounting hole rotating sleeve 16 rotating sleeves. Screw threads; the axial bottom end surface of the rotating sleeve 4 of the fixed column is provided with a through hole communicating with the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com