Filling plug screwing and heat sealing integrated machine

An all-in-one machine and liquid injection technology, applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve the problems of difficult to meet production requirements, high labor intensity, high cost, and meet the requirements of ensuring heat sealing quality, The effect of improving work efficiency and meeting output requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to facilitate understanding of the present invention, the present invention enumerates the following examples. It should be clear to those skilled in the art that the embodiments are only for helping to understand the present invention, and should not be regarded as specific limitations on the present invention.

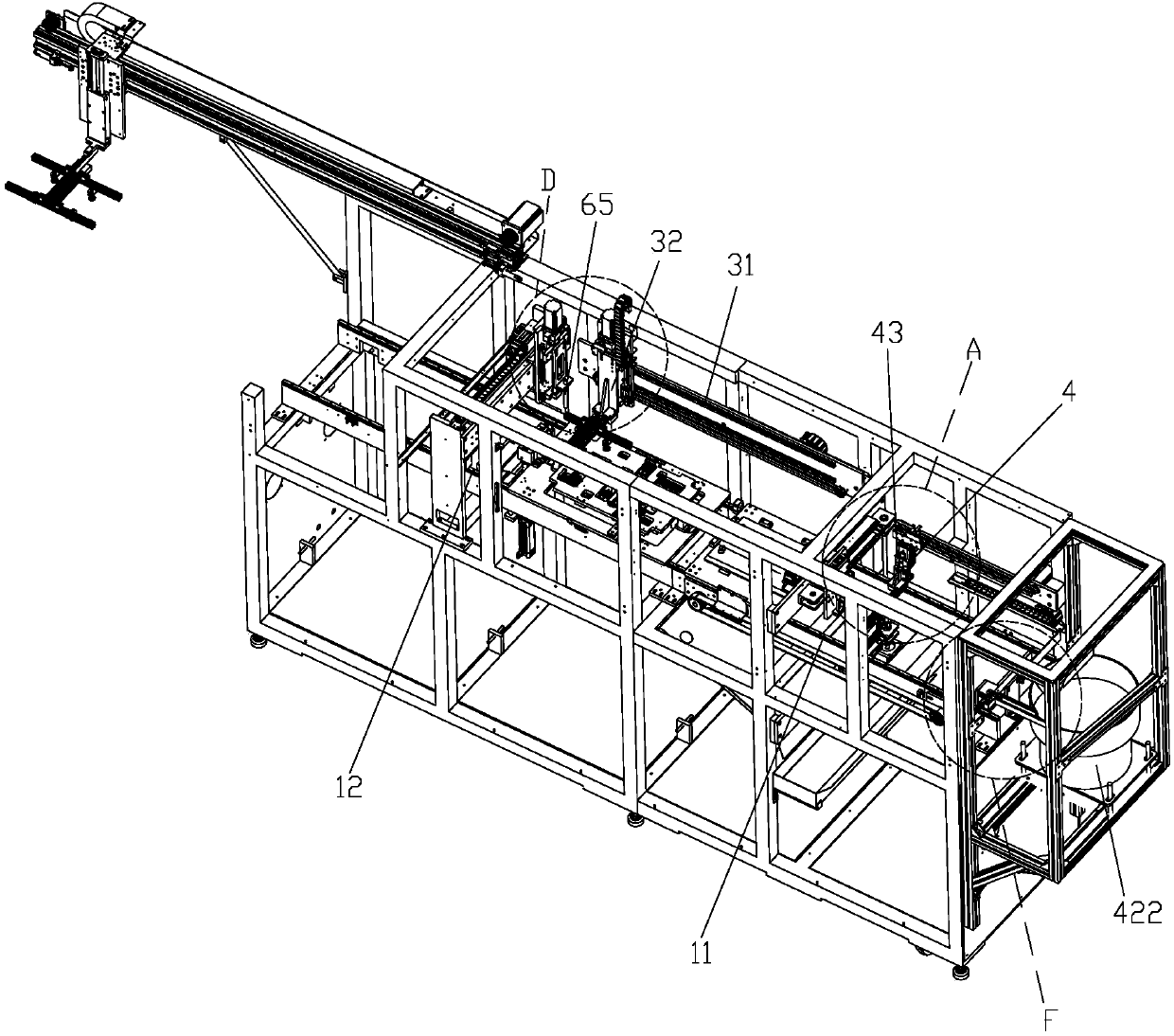

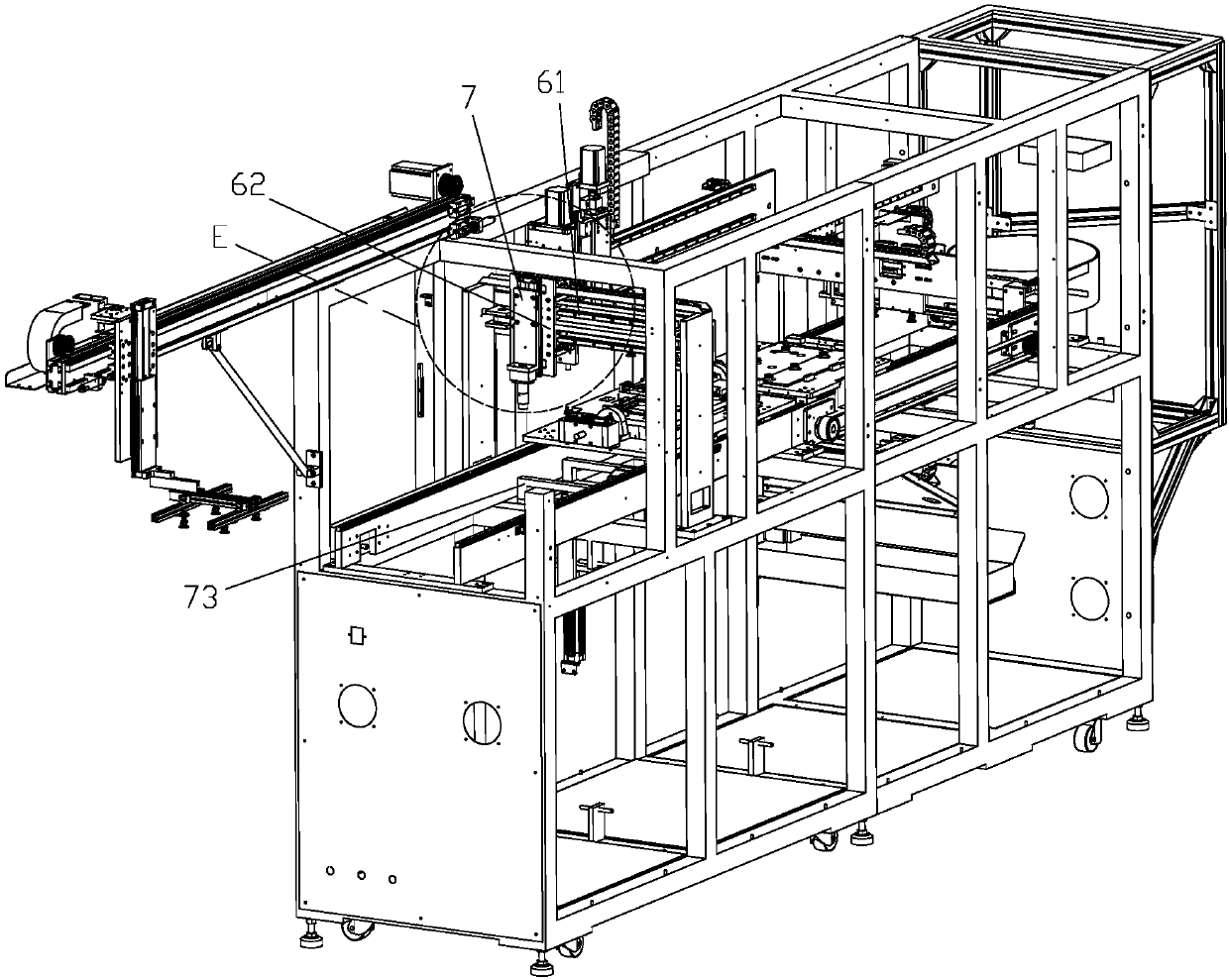

[0032] like Figure 1 to Figure 11As shown, a liquid injection plug screw cap heat sealing machine includes a frame 1, and the frame 1 is provided with a first bottom slide rail 11 and a second bottom slide rail 12; the first bottom slide rail 11 The upper frame is provided with a liquid injection plug mobile workbench 13 which can slide along its longitudinal direction for placing the battery cover taken out from the injection molding machine. The liquid injection plug is sucked and placed on the liquid injection hole of the battery cover, and the placed liquid injection plug is screwed into the automatic pick-and-place screw cap assembly in the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com