A fiber optic adapter structure

An optical fiber adapter and optical fiber pin technology, which is applied in the field of optical communication, can solve the problems of long length of fiber pin 4, insufficient electromagnetic shielding performance of fiber optic adapters, and insufficiently compact optical device packaging, so as to reduce electromagnetic wave leakage and ensure optical transmission. The effect of transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

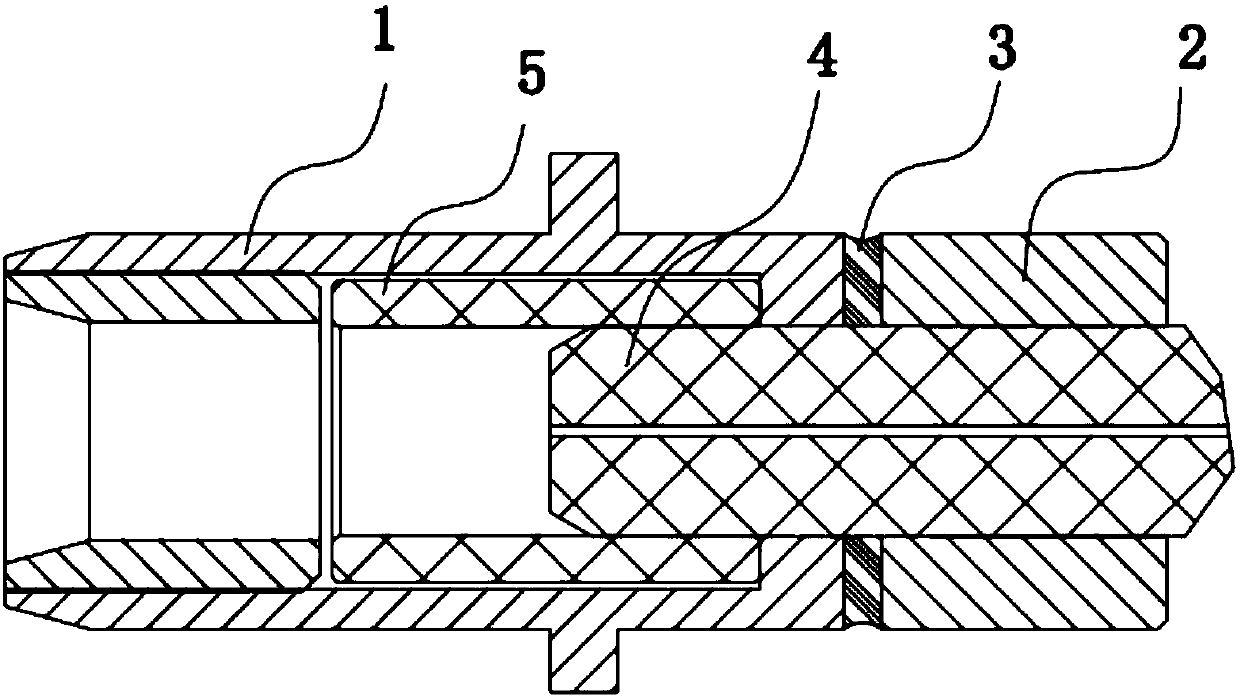

Embodiment 1

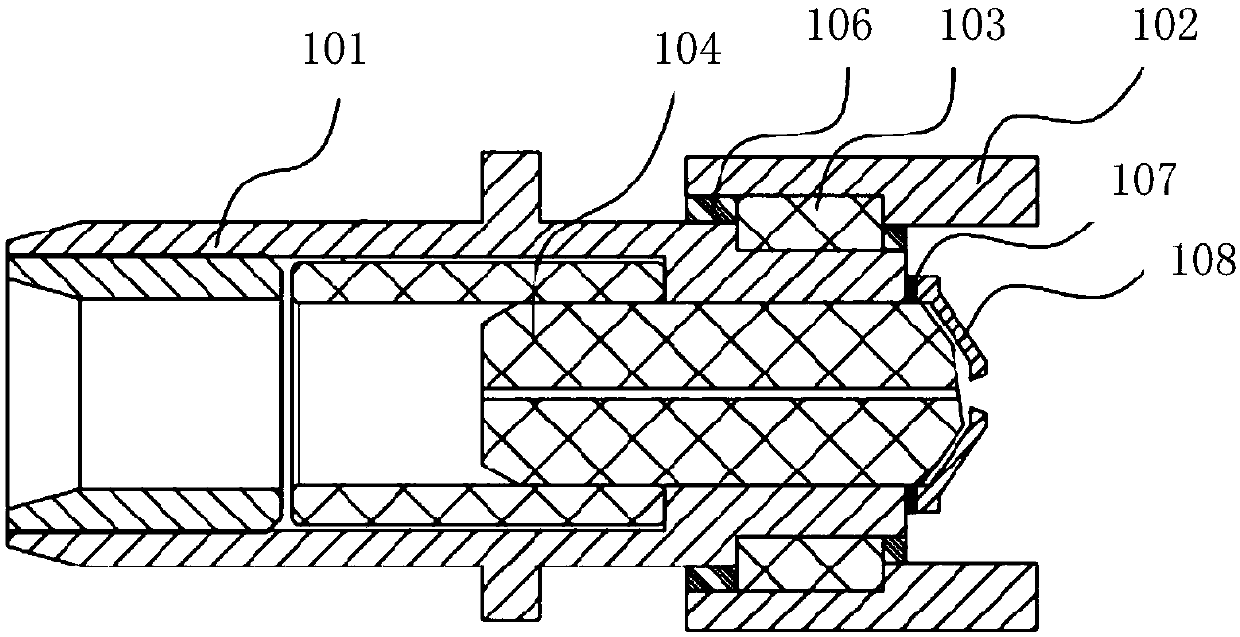

[0045] Embodiment 2 of the present invention provides an optical fiber adapter structure, such as figure 2 As shown, it includes a metal flange 101, a pipe body 102, an insulating ring 103, an optical fiber ferrule 104, and the structure also includes a shielding ring 108, specifically:

[0046] The optical fiber ferrule 104 is embedded in the metal flange 101, and the shielding ring 108 is fixed on the bottom of the metal flange 101 by conductive glue 107; wherein, the shielding ring 108 covers the ferrule 104 , and reserved a hole only for the laser signal to pass through;

[0047] The pipe body 102 is sleeved on the bottom of the metal flange 101 , and the insulation between the pipe body 102 and the metal flange 101 is realized by the insulating ring 103 .

[0048] The embodiment of the present invention provides an optical fiber adapter structure. The metal flange 101, the insulating ring 103 and the tube body 102 are radially assembled from the inside to the outside, w...

Embodiment 2

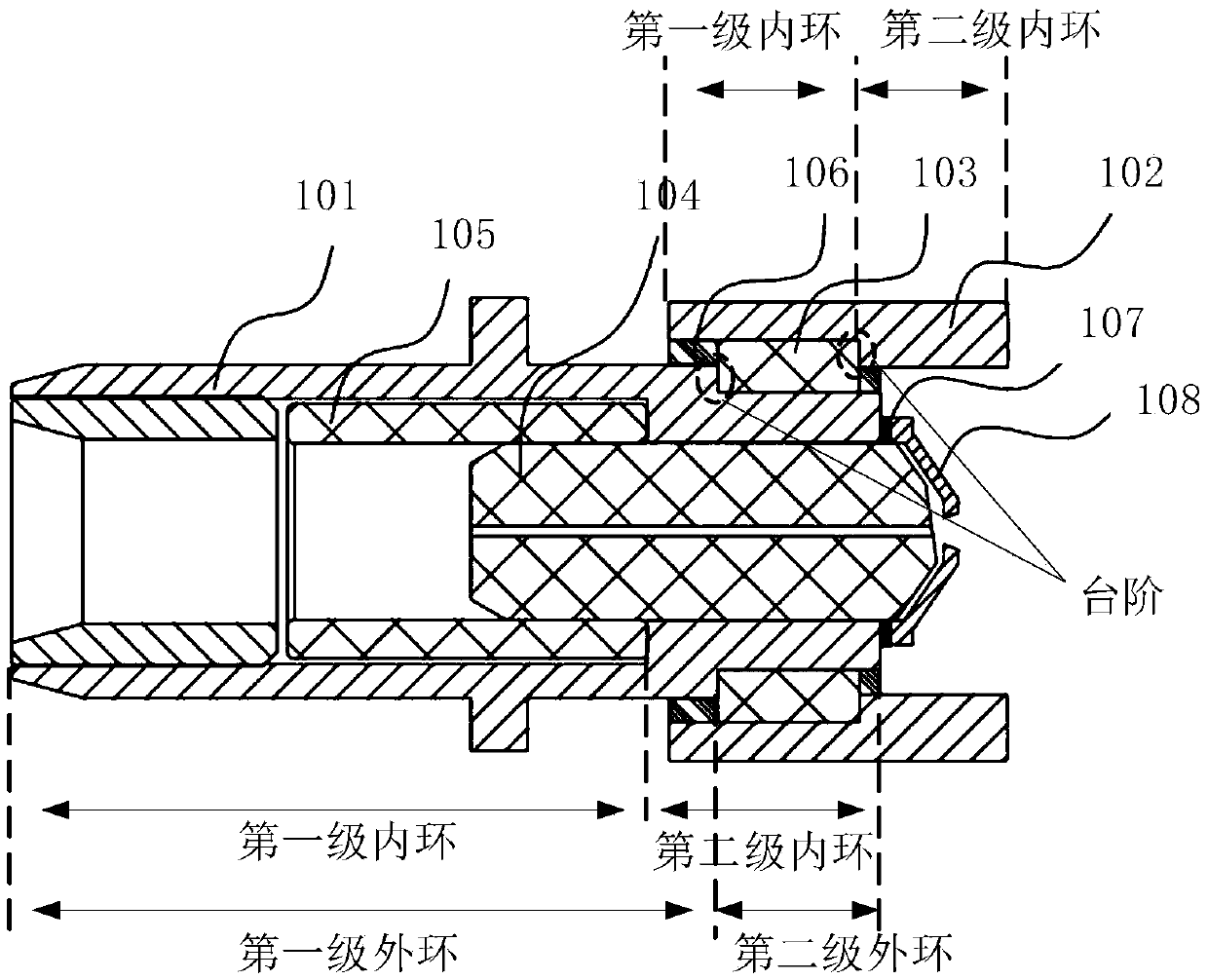

[0058] Embodiment 2 of the present invention provides an optical fiber adapter structure, such as image 3 As shown, it includes metal flange 101, pipe body 102, insulating ring 103, optical fiber ferrule 104 and sleeve 105, and the structure also includes insulating glue 106, conductive glue 107 and shielding ring 108, specifically:

[0059] The first-stage inner ring of the metal flange 101 is provided with the sleeve 105, and the second-stage inner ring is embedded with the pin 104, wherein the inner diameter of the second-stage inner ring is smaller than that of the first-stage inner ring , and the metal flange 101 is located on the outer wall of the second-level inner ring, and a second-level outer ring is provided, and the diameter length of the second-level outer ring is smaller than the first-level outer ring of the metal flange 101, and the The first-level outer ring is the outer wall of the main body of the metal flange 101; the metal flange 101 is located on the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com