Sealed floor drain for preventing water from leaking in dehydrating process

A technology of sealing ground and rotating plates, which is applied in waterway systems, water supply devices, drainage structures, etc. It can solve the problems of water leakage around the floor drain, poor sealing between dehydration pipes and sewers, easy loss of cover plates and filter nets, etc., and achieves increased Airtightness, labor saving, and the effect of avoiding the loss of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

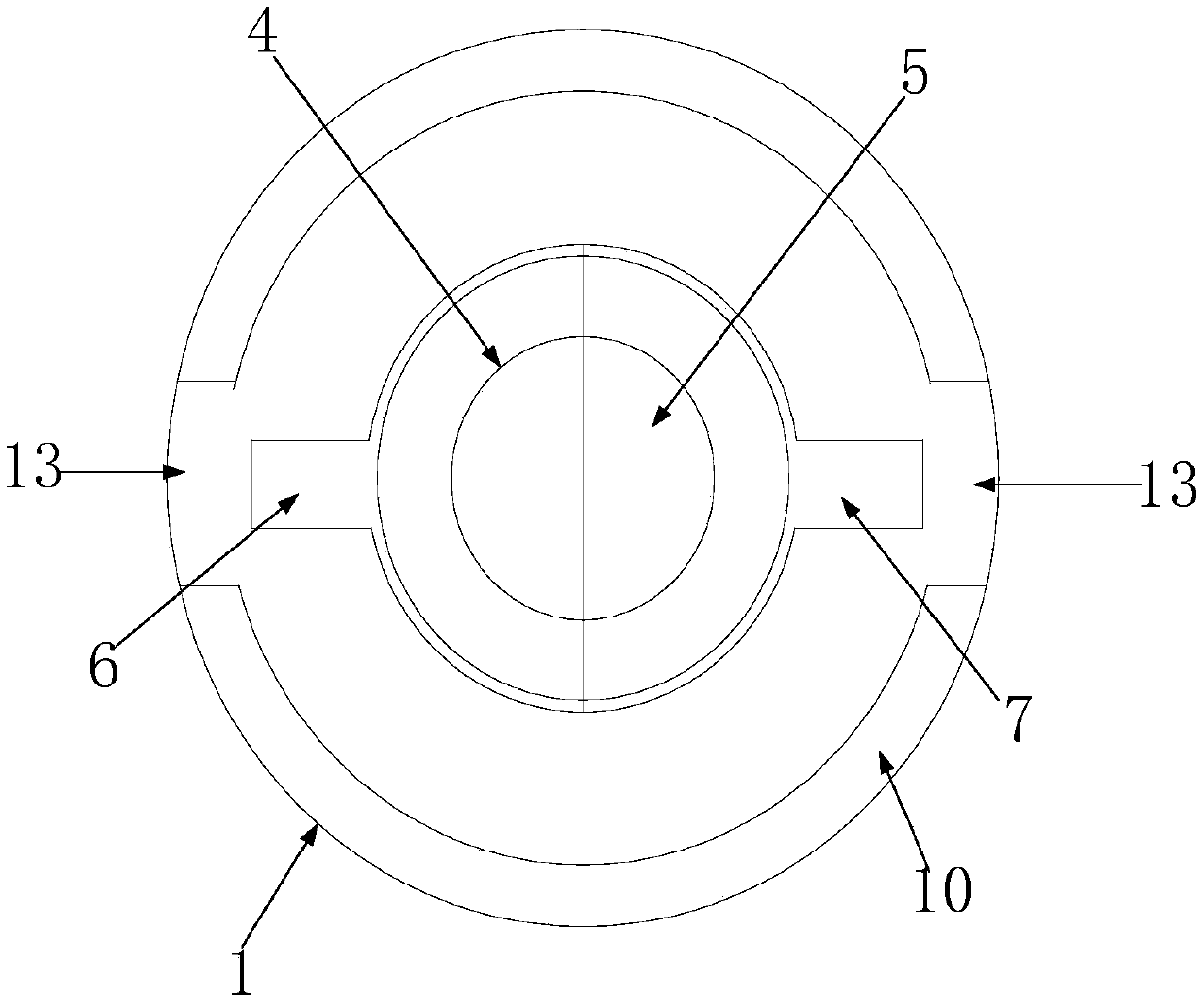

[0022] Such as Figure 1 to Figure 2 As shown, the sealed floor drain to prevent water leakage during dehydration includes a base 1 and a pressure pipe 2. The base 1 is a barrel-shaped structure without a cover, and a through hole 3 is provided at the bottom, and a sealing ring is provided on the edge of the through hole 3. In order to achieve filtration For the purpose of hair, a filter screen 12 is arranged below the through hole 3 . A first rotating plate 4, a second rotating plate 5, a first rotating rod 6 and a second rotating rod 7 are arranged inside the base 1, and the right end of the first rotating plate 4 is in contact with the left end of the second rotating plate 5 to form a basin structure. The basin opening matches the through hole 3, the left end of the first rotating plate 4 is fixedly connected to the right end of the first rotating rod 6, the right end of the second rotating plate 5 is fixedly connected to the left end of the second rotating rod 7, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com