Lubrication structure of a high-speed planetary reducer

A planetary reducer and lubricating structure technology, applied in the mechanical field, can solve the problems of high noise, unbalanced locking sleeve, small range of motor shaft diameter, etc., and achieve the effect of low noise and stable connection rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

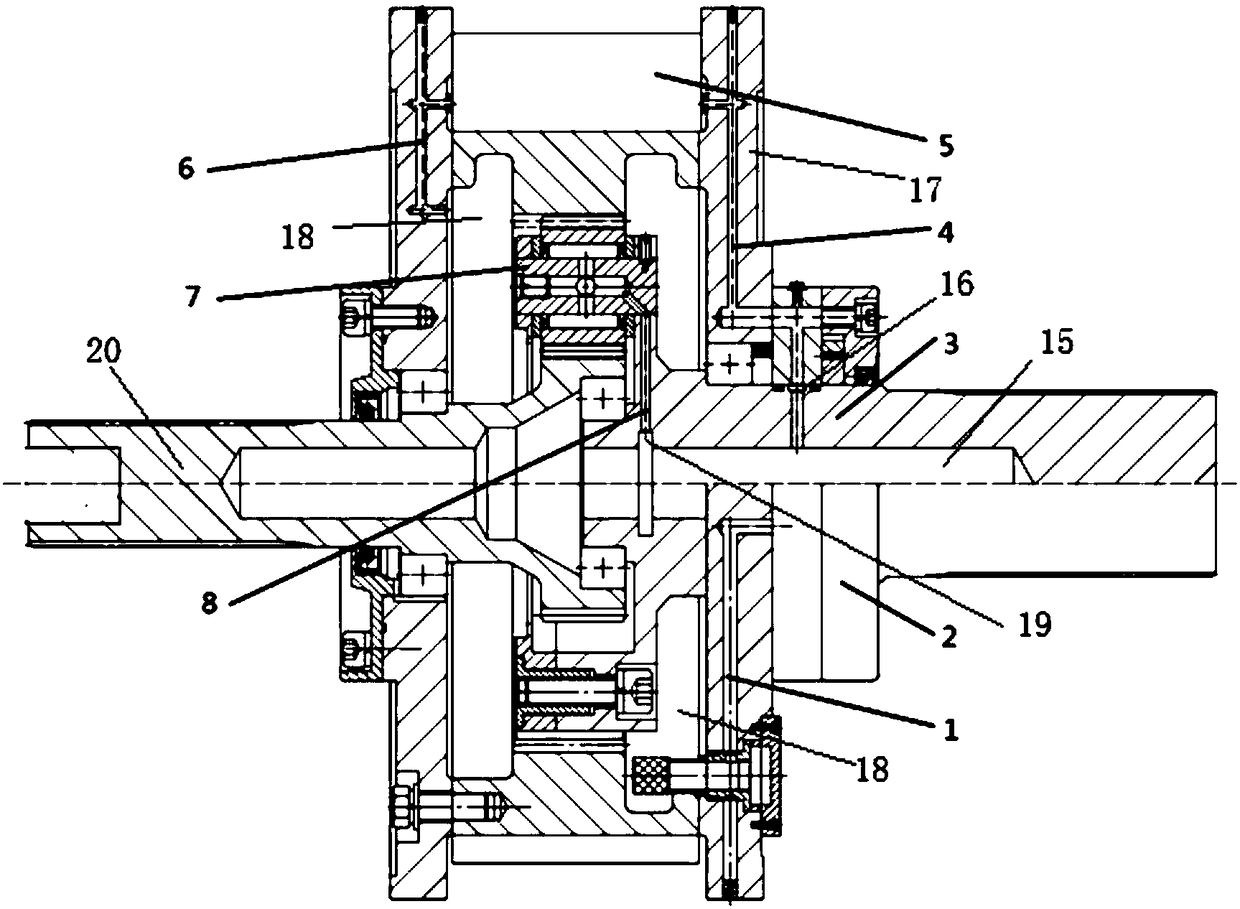

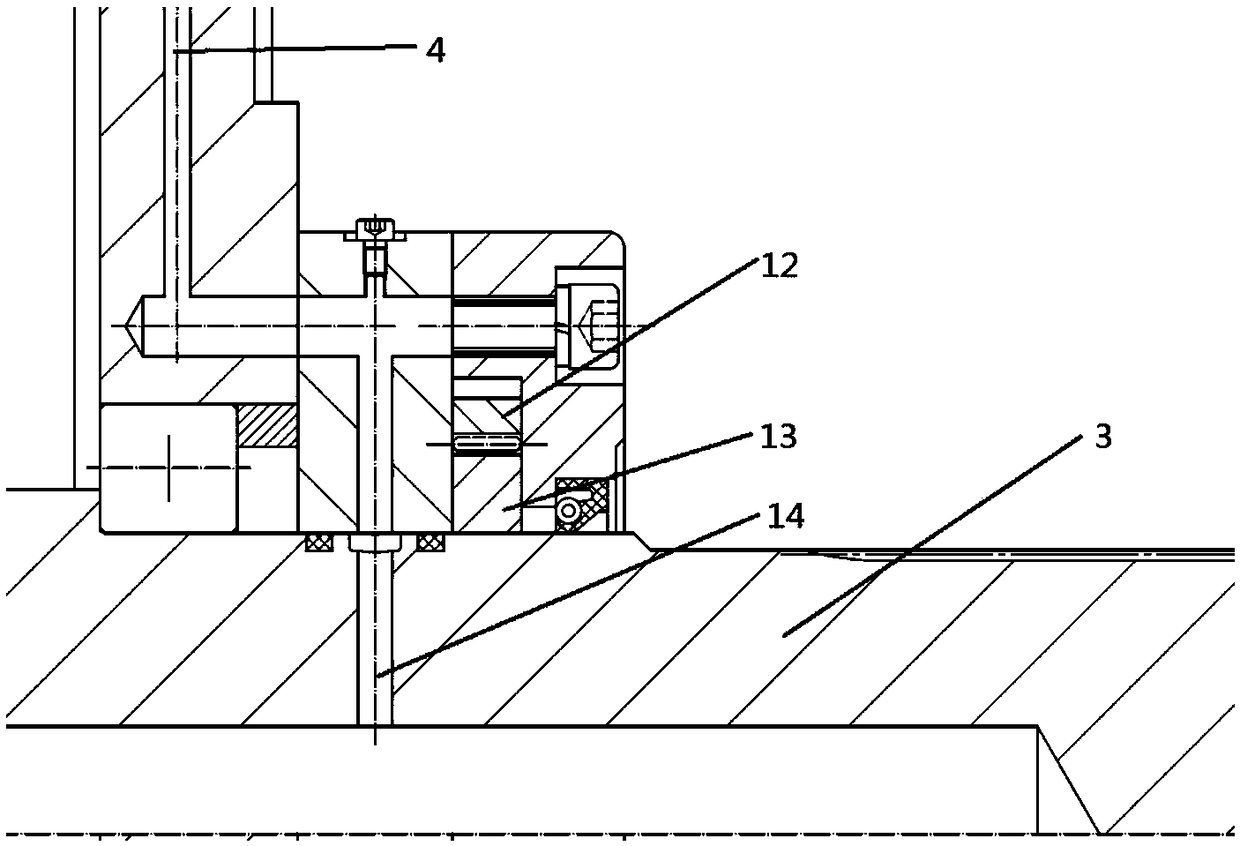

[0028] Such as Figure 1-3 The lubrication structure of a high-speed planetary reducer shown includes a housing 17, a gear mechanism 7 is installed in the housing 17, a box 18 is formed between the gear mechanism 7 and the housing 17, and the gear mechanism 7 is connected to the output shaft 3. The output shaft 3 is formed with a cavity 15 for containing lubricating oil, and the output shaft 3 is formed with an outer oil groove 16. The cavity 15 communicates with the outer oil groove 16 through the output shaft pressure oil passage 14, and the outer casing 17 is formed with an outer oil groove 16. Connected pressure oil passage 4, a radiator 5 is installed above the casing 17, and the pressure oil passage 4 surrounds the radiator 5 to dissipate heat and spray lubricating oil on the gear mechanism 7; the lower part of the box body 18 communicates with the gear oil pump through the negative pressure oil passage 1 2. The gear oil pump 2 is connected with the outer oil tank 16; th...

Embodiment 2

[0035] Such as Figure 5-7 As shown, the gear mechanism 7 is connected with an input shaft 20, and the input shaft 20 is locked and connected with the motor shaft 22 through a locking sleeve 21. The locking sleeve 21 includes a locking sleeve body 23, and the locking sleeve body 23 is symmetrically provided with The vertical groove 24 and the locking sleeve body 23 on both sides of the vertical groove 24 are connected through the upper ring body 25 , and are formed with opposite threaded holes 27 , and the upper ring body 25 is provided with a horizontal groove 26 perpendicular to the vertical groove 24 .

[0036] The vertical groove 24 is on the central axis of the horizontal groove 26 .

Embodiment 3

[0038] In order to ensure the wear resistance of the sun gear and the planetary gear in the gear mechanism, the composition of the sun gear and the planetary gear is as follows: zinc 83-86%, iron 4-8%, aluminum 2-8%, silicon 2.4-3%, carbon 0.1% ~1%, copper 0.2~0.5%, magnesium 0.5~1%, vanadium 0.1~0.5%, chromium 0.005~0.007%, lead 0.002~0.005%, titanium 0.003~0.008%. Add the above materials into the furnace in proportion, heat at high temperature to melt, stir, and the heating rate is 6 degrees Celsius per minute and 3 degrees Celsius per minute, mixed and heated alternately; the melting time is 2.5 to 3 hours, stirring once every half an hour, Stir for 1 to 3 minutes each time; then transport the molten metal to the holding furnace, then inject it into the die-casting machine for die-casting, cool down, and obtain the preliminary products of the sun gear and the planetary gear, and then polish and drape to obtain the final product. After testing, the elongation performance, te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com