Bearing with dust-proof and heat dissipation functions

A functional and dust-proof technology, applied in the direction of bearing components, shafts and bearings, bearing cooling, etc., can solve the problems of reducing the friction coefficient of mechanical load, the bearing can not work normally, the service life of the bearing is shortened, etc. Dustproof and heat dissipation effect, ensure normal use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

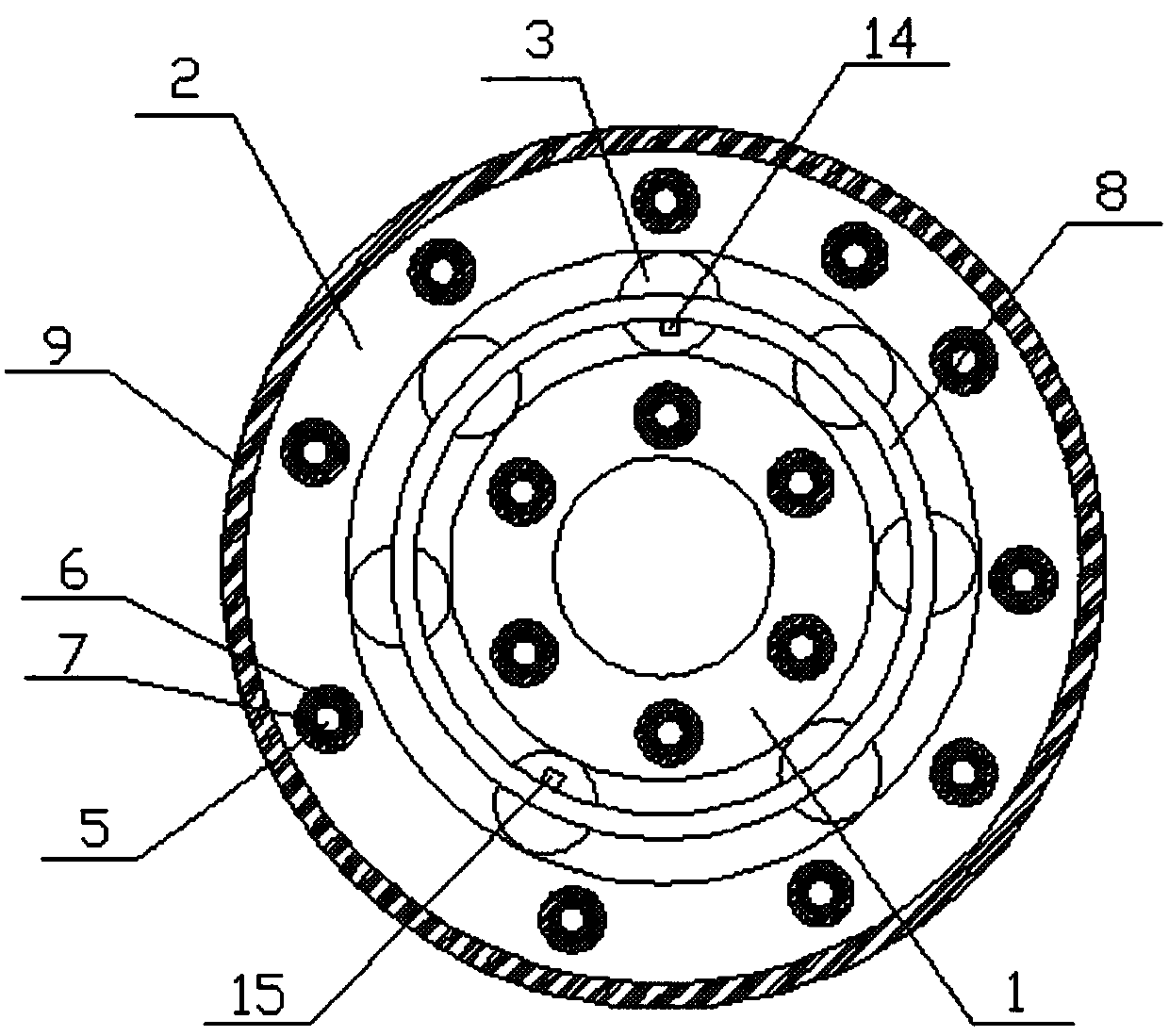

[0019] Such as Figure 1-Figure 4 As shown, a bearing with dust-proof and heat-dissipating functions includes an inner ring 1, an outer ring 2, a ball 3 and a plastic dust cover 4, the ball 3 is arranged between the inner ring 1 and the outer ring 2, and the inner ring 1 Both the ring 1 and the outer ring 2 are provided with a plurality of heat dissipation holes 5, the inner wall of the heat dissipation holes 5 is provided with a heat conduction layer 6, the inner wall of the heat conduction layer 6 is provided with a heat dissipation layer 7, and one side of the ball 3 is provided with Cooling pipe 8, the inner cavity of the cooling pipe 8 is filled with coolant, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com